Spiral gas distributor

A gas distributor and spiral technology, applied in the field of gas distribution devices, can solve the problems of easily blocked distribution channels, insufficient distribution points, complex structure, etc., so as to alleviate flue gas concentration or dead zone, facilitate popularization and application, and improve desulfurization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

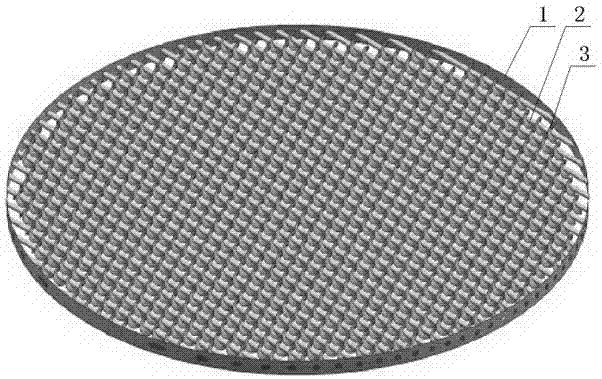

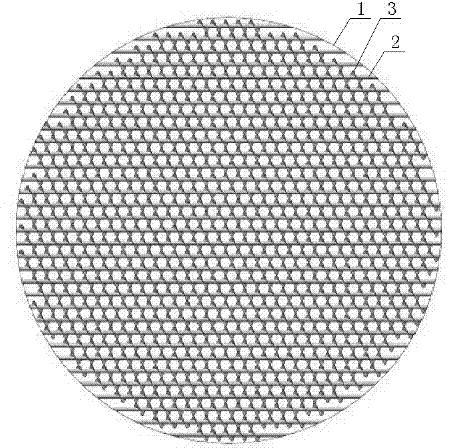

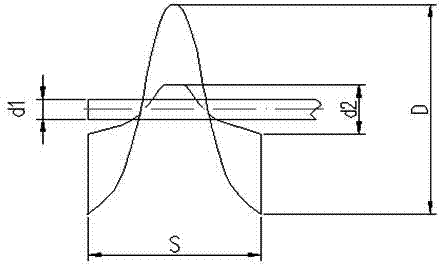

[0015] Such as figure 1 As shown in -3, the spiral gas distributor includes a circular support frame 1 fixedly connected to the inner wall of a large-scale sulfur dioxide absorption tower with a diameter of 12.5m, and 33 main shafts 2 and 33 main shafts 2 are fixedly connected in the circular support frame 1 Arranged in parallel, each main shaft 2 is connected with a helical blade 3, and the helical blades 3 with the main shaft 2 are placed in a right-hand direction parallel to the inlet direction of the flue gas, and are arranged in an equidistant staggered manner.

[0016] The diameter d1 of the main shaft 2 is 0.114m, and the distance L between two adjacent main shafts 2 is 0.37m. The pitch S of the helical blade 3 is 0.38m, the inner diameter d2 is 0.114m, the outer diameter D is 0.37m, the blade width C of the helical blade 3 is 0.128m, and the blade thickness b is 0.005m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com