A method for ultra-fine crushing of the cell wall of large seaweed Asparagus

A technology of fine crushing and cell wall, applied in the field of ultrafine crushing of the cell wall of large seaweed asparagus, achieving the effect of low processing cost, easy access to processing equipment, and less labor required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

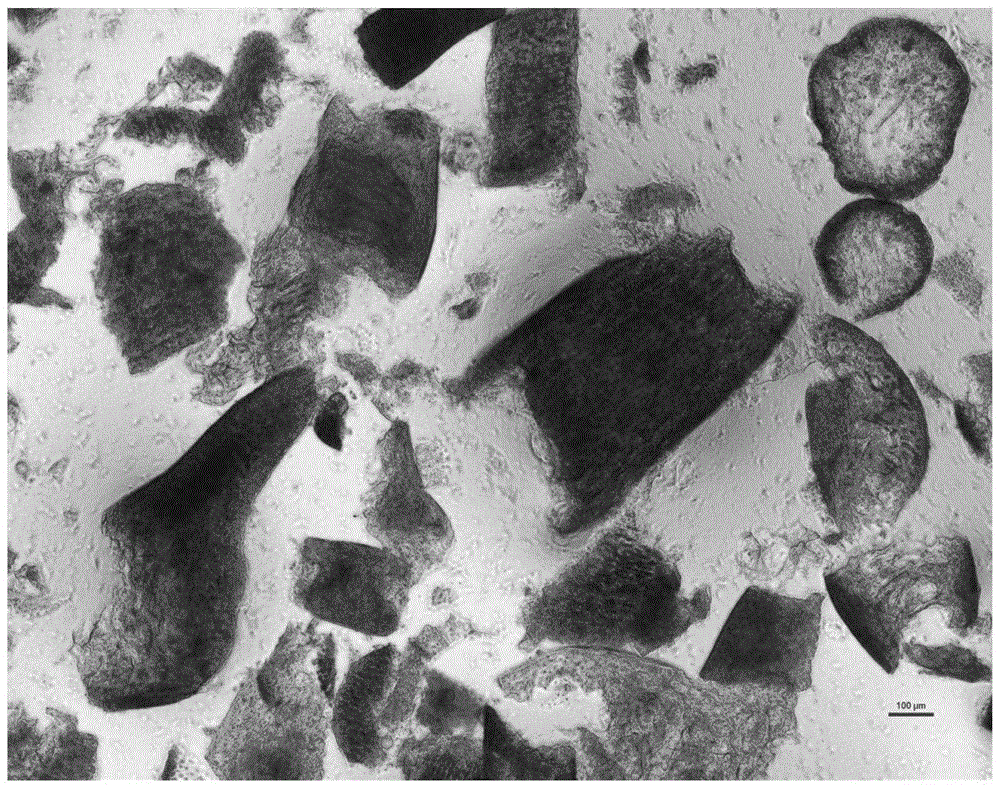

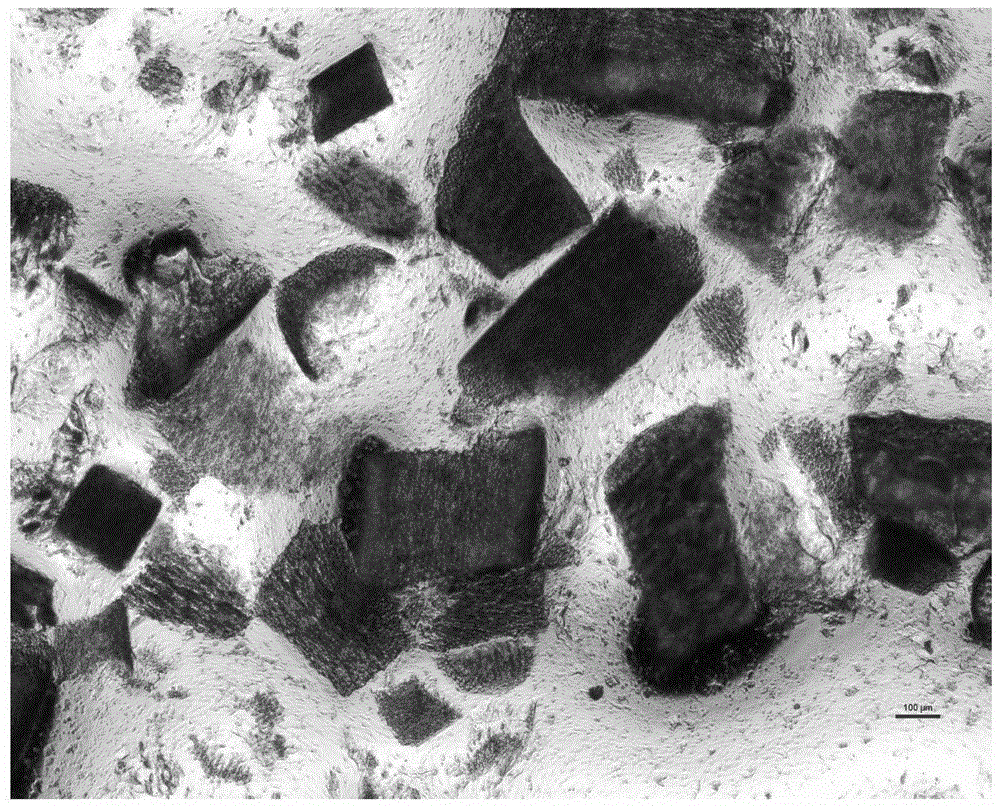

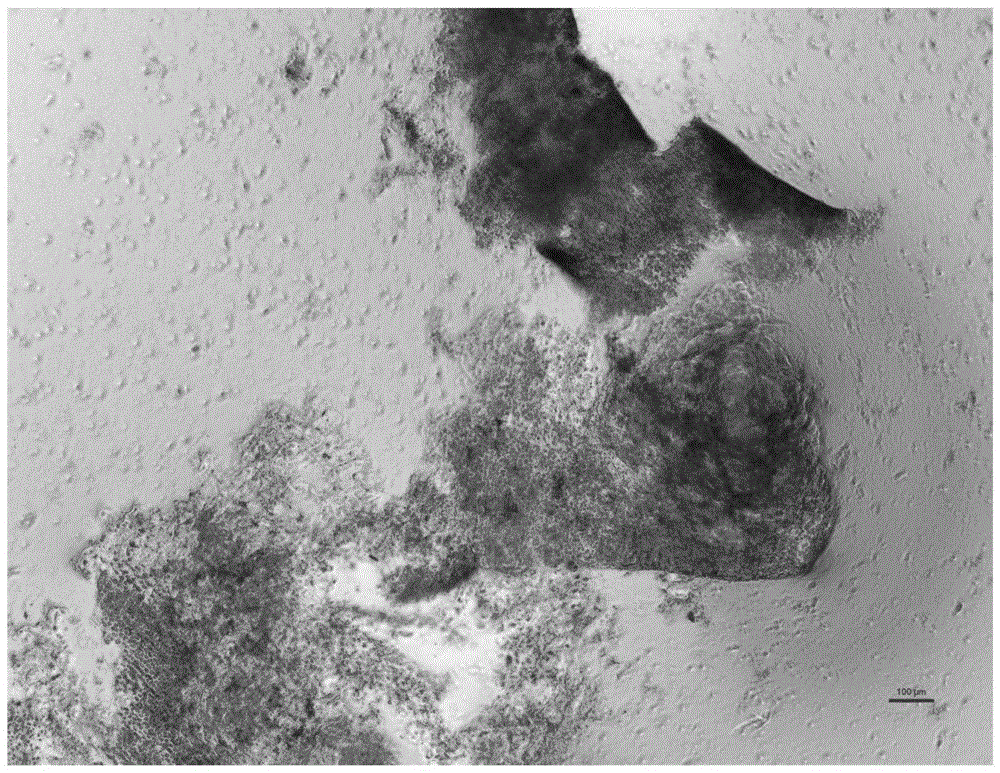

Image

Examples

Embodiment 1

[0019] (1) Fresh dark reddish-brown thick asparagus-981 (981 asparagus) from Nan'ao Island, Shantou, Guangdong, or asparagus-981 stored at low temperature, washed with water and drained.

[0020] (2) Mix the above-mentioned asparagus with PBS buffer according to the ratio of weight to volume (W (g) / V (ml)), asparagus: PBS buffer = 1:2, mix and put into cylindrical ice Store in the freezer at -20°C for 5 hours.

[0021] (3) Adjust the ultra-fine crushing device so that the dihedral angle formed by the ice-shaving knife and the ice-shaving table is 50°-60°, and the vertical height between the blade of the ice-shaving knife and the ice-shaving table is less than 0.5mm.

[0022] (4) Place the above-mentioned frozen seaweed ice cubes in the above-mentioned adjusted ultra-fine crushing device for crushing.

[0023] (5) Collect the broken seaweed ice in the above step (4), melt the broken seaweed ice at 4°C and then freeze it again at -20°C, then repeat the above breaking, repeat 5 ...

Embodiment 2

[0026] (1) Fresh dark reddish-brown thick asparagus-981 from Nan'ao Island, Shantou, Guangdong Province or asparagus-981 stored at low temperature, washed with water and drained.

[0027] (2) Mix the above-mentioned asparagus with PBS buffer according to the ratio of weight to volume (W (g) / V (ml)), asparagus: PBS buffer = 1:2, mix and put into cylindrical ice Place in the tank at -80°C for 3 hours.

[0028] (3) Adjust the ultra-fine crushing device so that the dihedral angle formed by the ice-shaving knife and the ice-shaving table is 50°-60°, and the vertical height between the blade of the ice-shaving knife and the ice-shaving table is less than 0.5mm.

[0029] (4) Place the above-mentioned frozen seaweed ice cubes in the above-mentioned adjusted ultra-fine crushing device for crushing.

[0030] (5) Collect the broken seaweed ice in the above step (4). The crushed seaweed ice melts at 25°C and freezes again at -80°C, then repeats the above breaking. Repeat 3 times to compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com