Automobile bumper color registration and spraying process

A bumper and bumper cover technology, which is applied to the coating, the device for coating liquid on the surface, and the pretreatment surface, etc., can solve the problems such as the increase of the environmental particle index of the production line, the difficulty of cleaning, and the reduction of the spraying quality, so as to avoid The effect of product scratches, reducing paint slag pollution, and saving intermediate glue tearing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

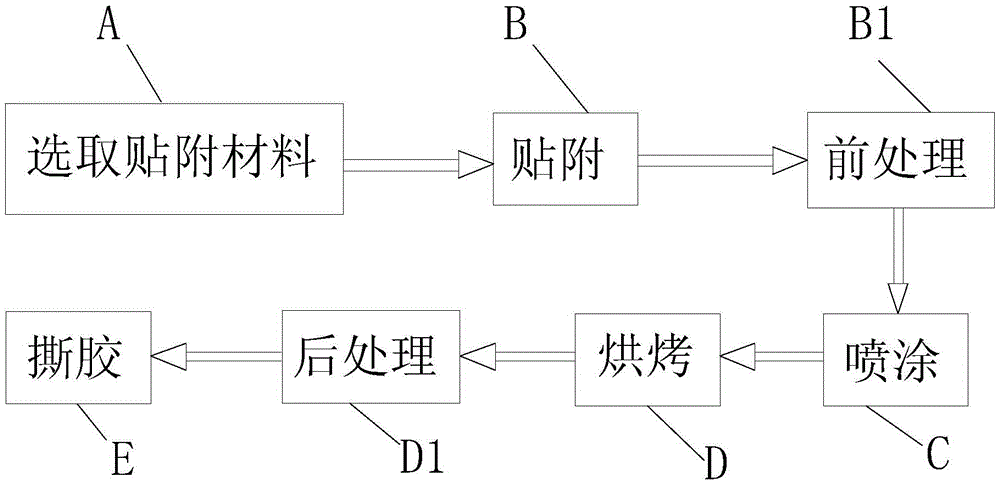

[0047] A kind of automobile bumper color registration and spraying process, this process comprises the following steps (see figure 1 Process flow chart shown):

[0048] A. Select the attachment material:

[0049] Select tapes and films with high viscosity, high temperature resistance, moderate softness, and flat edges as the attachment raw materials, the tape is 3M4737 tape; the film is a masking paper film integrating masking paper;

[0050] The physical properties of the selected 3M4737 tape are as follows: width: 5mm, high temperature resistance above 120 °C, soft tape, straight lines and no burrs; the physical properties of the selected film are as follows: high temperature resistance above 120 °C, the overall width is 700mm.

[0051] B. Attach:

[0052]Place the bumper flat on the workbench, first attach the 3M4737 tape to the edge of the color separation tank and the bottom of the color separation tank, use tools to compact the 3M4737 tape, then attach the film to th...

Embodiment 2

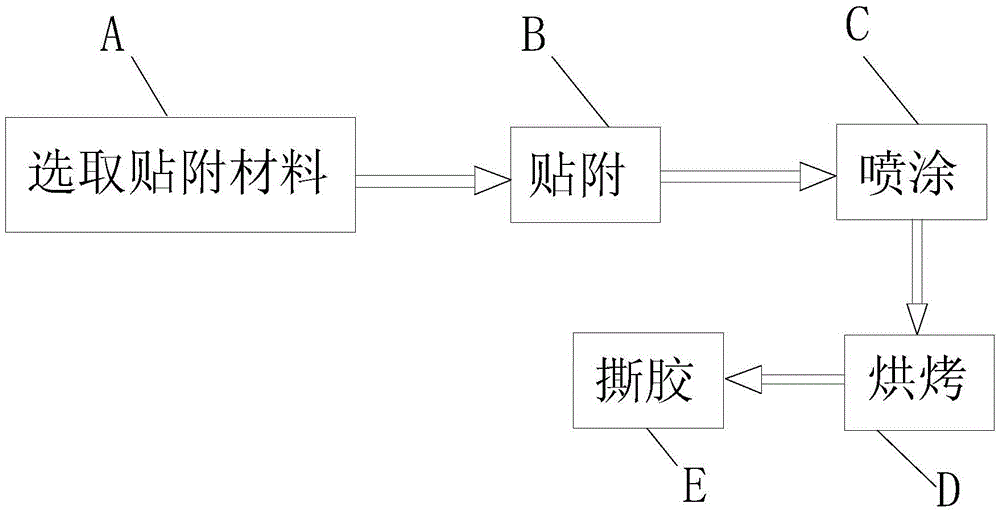

[0064] A kind of automobile bumper color registration and spraying process, this process comprises the following steps (see figure 2 Process flow chart shown):

[0065] A. Select the attachment material:

[0066] Select tapes and films with high viscosity, high temperature resistance, moderate softness, and flat edges as the raw materials for attachment, and the tapes described are 3M4737 tapes;

[0067] The physical properties of the selected 3M4737 tape are as follows: width: 3mm, high temperature resistance of 100 °C, soft tape, straight lines and no burrs; the physical properties of the selected film are as follows: high temperature resistance of 100 °C, the overall width is 500mm.

[0068] B. Attach:

[0069] Place the bumper flat on the workbench, first attach the 3M4737 tape to the edge of the color separation tank and the bottom of the color separation tank, compact the 3M4737 tape with a tool, and then attach the film to the 3M4737 tape with double-sided tape , ...

Embodiment 3

[0077] A kind of automobile bumper color registration and spraying process, its step is the same as embodiment one, but relevant parameters are different:

[0078] In the step A, the width of the selected 3M4737 adhesive tape is: 8mm, resistant to high temperature of 110°C, the film is resistant to high temperature of above 110°C, and the overall width is 1000mm.

[0079] In the step C, the line speed during spraying is 2m / min, the spray gun pressure is 0.8Mpa, the flow rate is 200ml / min, the spray gun distance is 30cm, and the film thicknesses of the primer, topcoat and varnish are 15um, 28um, and 30um in sequence ,

[0080] In the step D, the baking temperature is 60° C., and the baking time is 85 minutes;

[0081] In the step E, when tearing the glue, ensure that the angle between the peeling surface of the 3M4737 tape and the bumper of the car is α=150 degrees, and the peeling speed is 0.2m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com