Method for controlling grinding efficiency and surface quality of particle-reinforced titanium-based composite material

A titanium-based composite material and particle-reinforced technology, which is applied in the direction of automatic grinding control devices, grinding machine parts, workpiece feed movement control, etc., can solve the problems of poor surface quality and low processing efficiency, and achieve improved processing Effects of improving surface quality, improving machining accuracy and efficiency, and omitting the grinding wheel dressing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1, rough grinding parameter setting, including grinding wheel linear speed 30m / s, workpiece feed speed 3000mm / min, grinding depth 0.030mm, grinding 1 time, grinding wheel without dressing.

[0020] Step 2, semi-finishing parameter setting, including grinding wheel linear speed 30m / s, workpiece feed speed 6000mm / min, grinding depth 0.015mm, grinding 4 times, grinding wheel without dressing.

[0021] Step 3, fine grinding parameter setting, including grinding wheel linear speed 30m / s, workpiece feed speed 9000mm / min, grinding depth 0.005mm, grinding 2 times, grinding wheel without dressing.

[0022] Step 4, light grinding parameter setting, including grinding wheel linear speed 30m / s, workpiece feed speed 12000mm / min, grinding 1 time, grinding wheel without dressing.

Embodiment 2

[0023] Embodiment 2. Verification test:

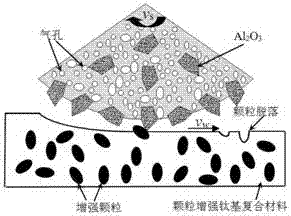

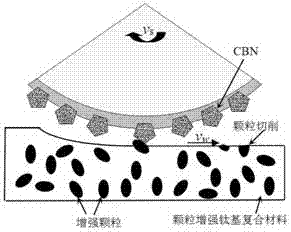

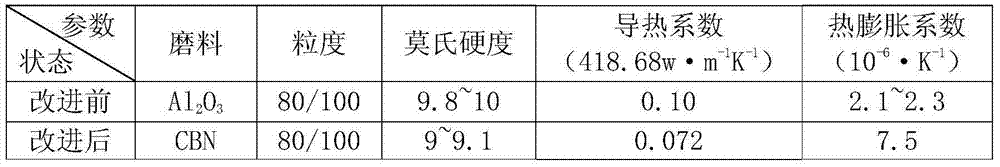

[0024] Comparative experiments were carried out from the aspects of abrasive types and grinding parameters to determine the process method that can effectively control the grinding efficiency and surface quality of particle-reinforced titanium matrix composites. The abrasive parameters of the traditional and the present application are shown in Table 1, the grinding parameters of the traditional and the control method of the present application are shown in Table 2 (corresponding respectively before and after improvement), and the (traditional) grinding wheel dressing parameters before improvement are shown in Table 3 , in the improved control method of the present application, there is no need to dress the grinding wheel. Table 2, v s , v w 、a p The symbols correspond to the grinding wheel linear speed, workpiece feed speed and grinding depth respectively.

[0025] Table 1 Abrasive parameters before and after improvement

[0026]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com