Strip steel surface rust removing apparatus

A strip steel and equipment technology, applied in the field of strip steel surface rust removal equipment, can solve the problems of high cost, human harm, large loss, etc., and achieve the effects of high processing accuracy, thorough rust removal, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

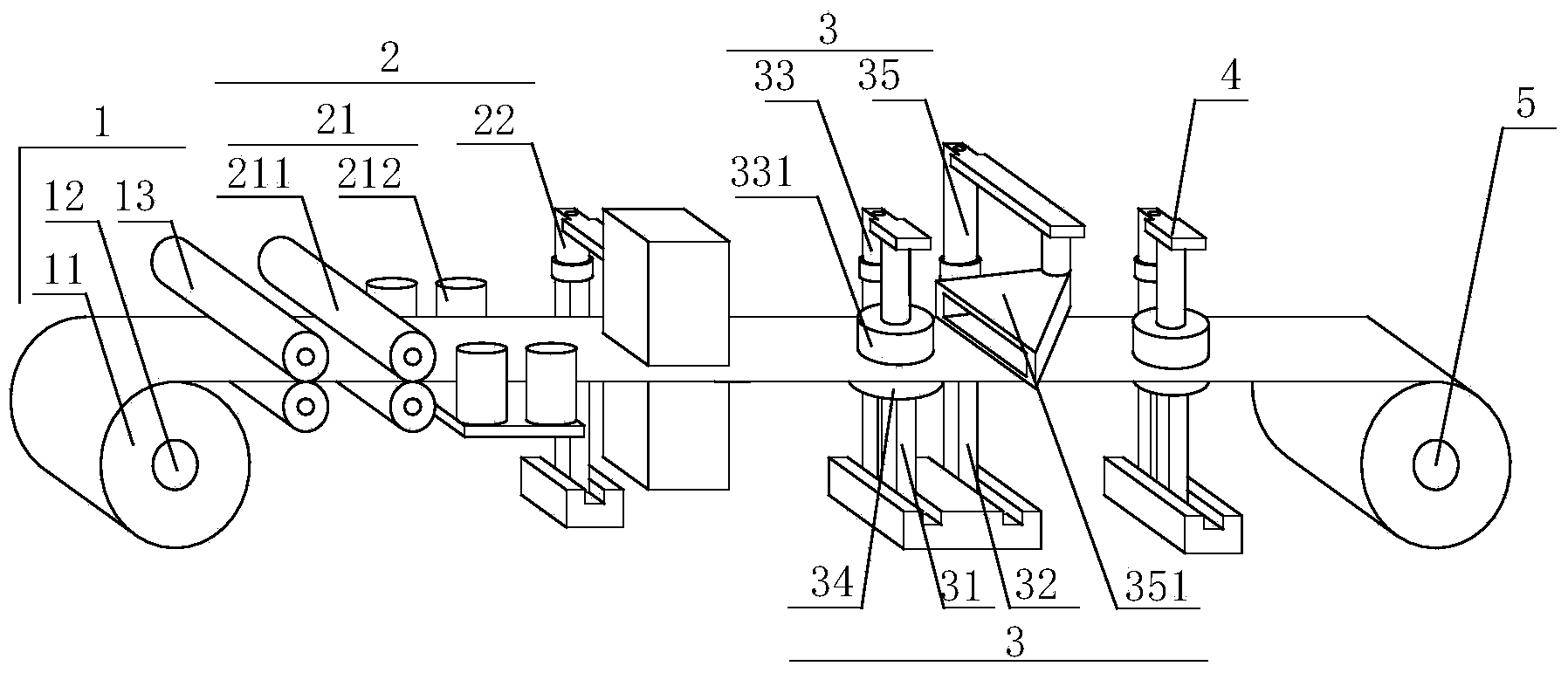

[0018] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a strip steel surface derusting equipment proposed by the present invention.

[0019] refer to figure 1 , a kind of steel strip surface derusting equipment that the present invention proposes, comprises: feeding device 1, detection device 2, derusting device 3, flushing device 4, winding device 5;

[0020] The feeding device 1 comprises a raw material rack 11, a first drive mechanism 12, and an uncoiling mechanism 13. The first driving mechanism 12 is used to drive the raw material rack 11 to rotate so as to send out the coiled steel strip. into a flat strip;

[0021] The detection device 2 includes a limit mechanism 21 and a CCD detection mechanism 22. The limit mechanism 21 is used to limit the horizontal and vertical positions of the flat steel strip during the feeding process, which includes a vertical limit mechanism 211 and a horizontal limit mechanism. Mechanism 212, the vertical limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com