Fireworks tight film packaging machine

A technology of tightening hoops and fireworks, which is applied in the field of fireworks tight hoop film packaging machines, which can solve the problems of rope loosening, unfavorable production, and high repair rate, and achieve the effects of avoiding easy loosening, reducing production costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

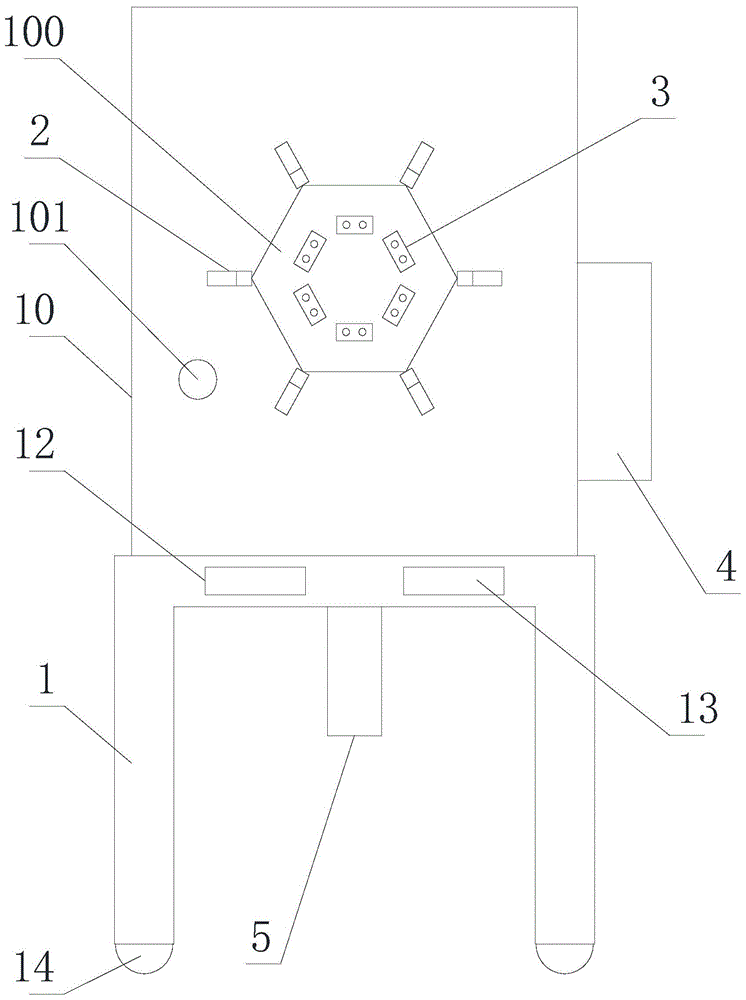

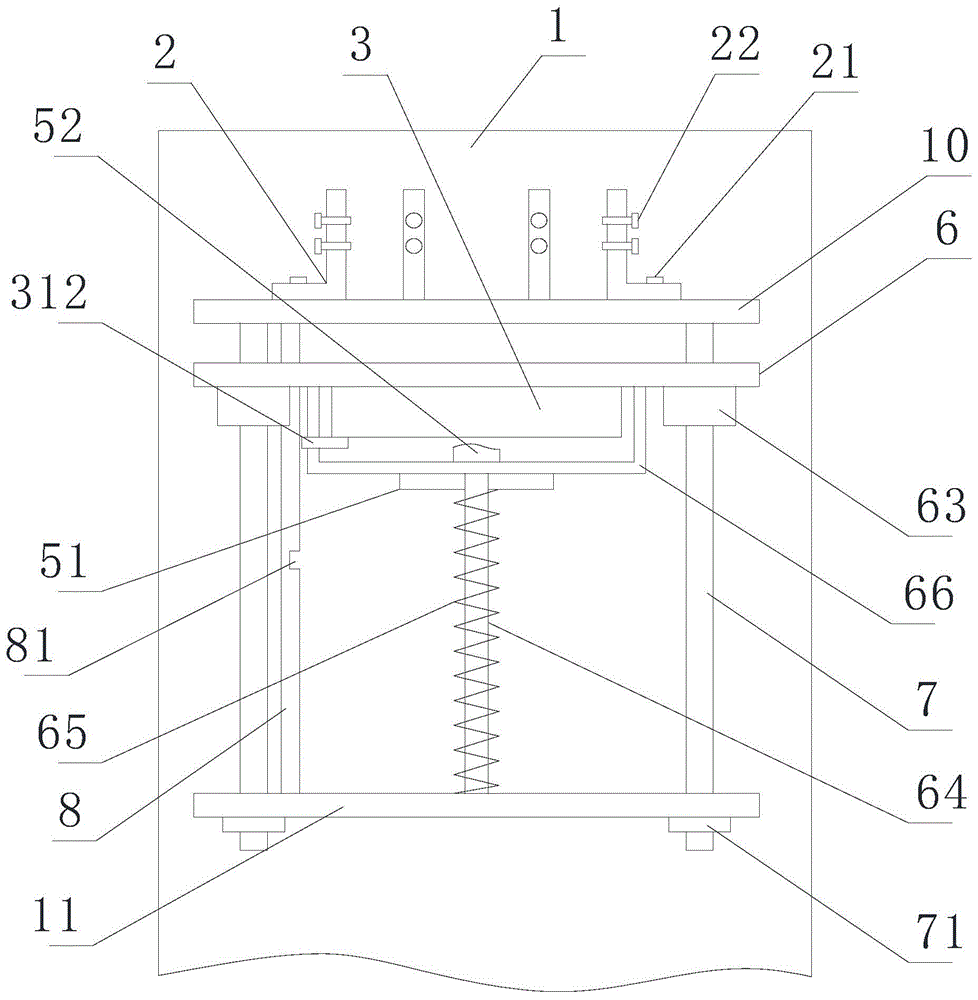

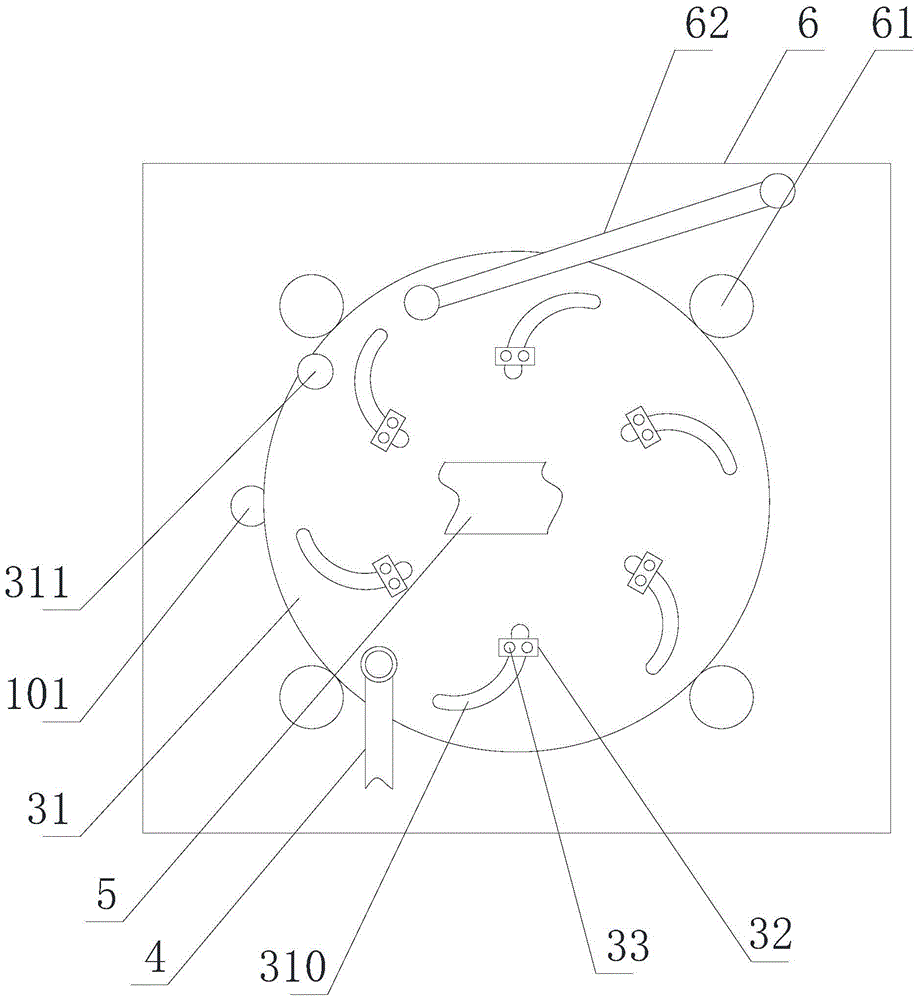

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, the fireworks tight film packaging machine includes a frame 1 and a first vertical plate 10 fixedly connected to the upper middle of the frame 1 with a positioning hole 100. The positioning hole can be a regular polygonal hole or a circular hole. The first vertical plate 10 on the outer edge of the hole 100 is provided with a fixing assembly 2 for fixing the fireworks on the first vertical plate 10, and a stretcher for stretching the tight membrane is provided at the center of the positioning hole 100. Component 3, the frame 1 is provided with a driving component 4 for driving the expansion component 3 to work and a control component 5 for controlling the return of the expansion component 3, and the first vertical plate 10 is provided with a control component 3 to move Stroke limit switch 101, the expansion assembly 3 includes a turntable 31, at least two sliders 32 movably connected to the turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com