Composition and method for roads, parking lots, and driving surfaces

A composition and polymer technology, applied in chemical instruments and methods, devices for coating liquids on surfaces, roads, etc., can solve problems such as increased sensitivity, performance degradation, and reduced lifespan of repaired parts, and achieves rapid solidification, Fast drying and curing time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Cationic asphalt sealer compositions were prepared by adding the following components to water in the amounts given and in the order listed.

[0071] .

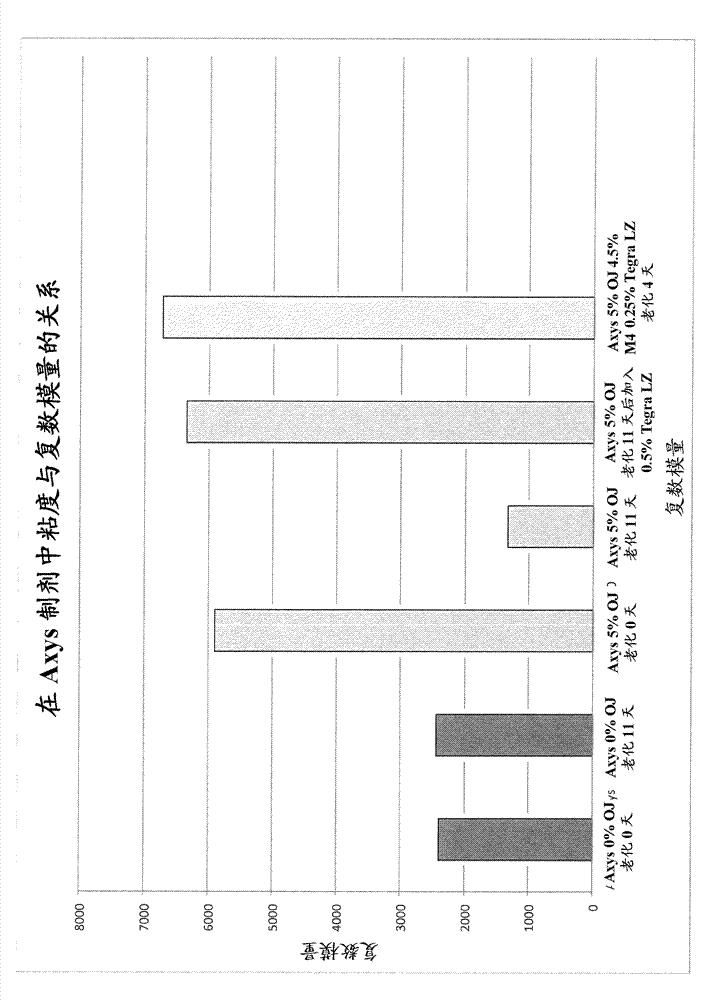

[0072] The complex modulus of the hardened sealant was 2300 kPa when the material was aged for only 4 hours before the test was started and then allowed to cure for 4 days (Composition A). The complex modulus of the hardened sealant was essentially the same when applied after 11 days of storage and allowed to cure for 17 hours (Composition B). The results are shown in the accompanying drawings.

[0073] A sealant composition comprising a polar polymer hardener (polyvinyl alcohol) was then prepared as follows:

[0074] .

[0075] When applied within 4 hours and allowed to cure for 4 days (Composition C), the complex modulus of the hardened sealant skyrocketed to 5900 kPa. However, when the composition (Composition D) was stored for 11 days, the composition settled to a point where it could not be reversed by mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| complex modulus | aaaaa | aaaaa |

| complex modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com