T-section steel pipe recycled concrete pier body

A technology of recycled concrete and steel pipes, applied in bridge materials, buildings, bridge construction, etc., can solve problems such as landslides, waste of land and resources, riverbed diversions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

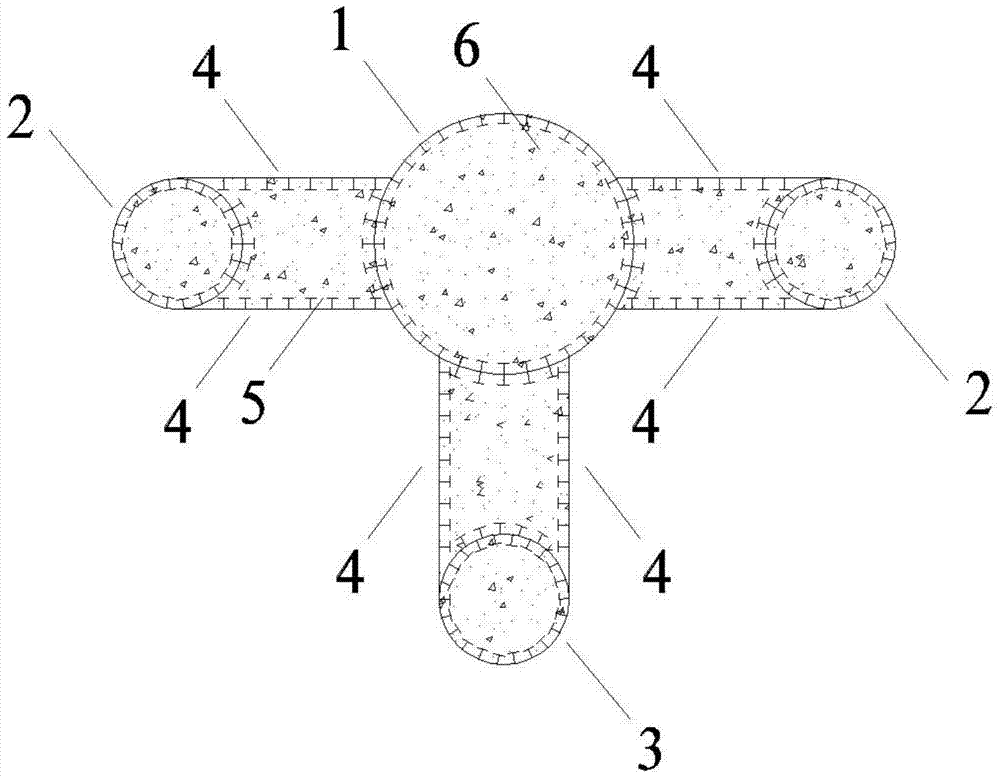

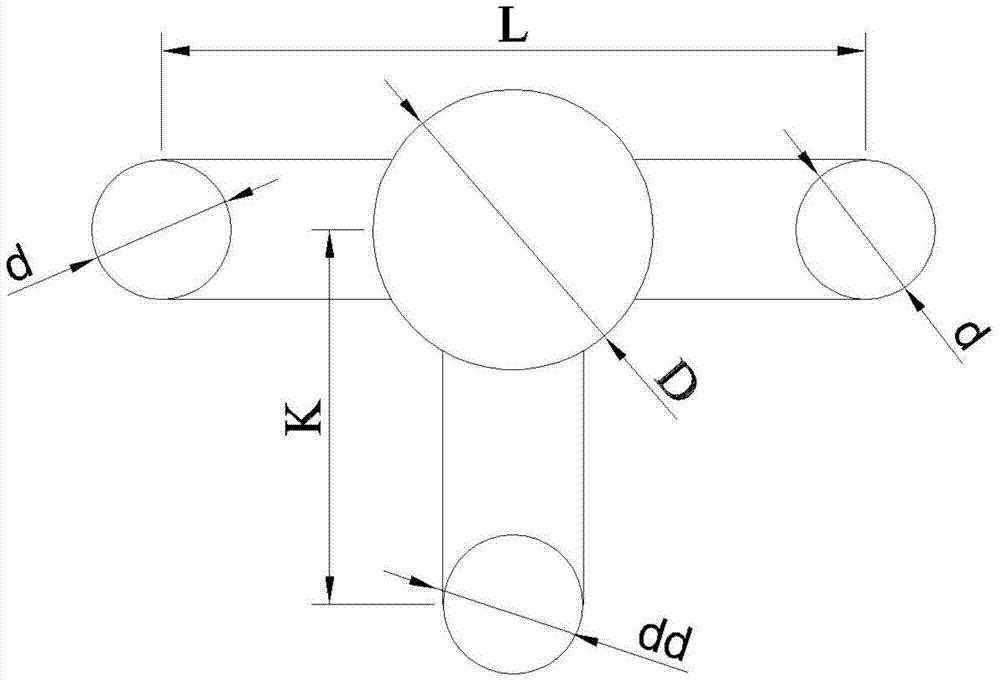

[0019] like figure 1 As shown, the T-shaped cross-section steel pipe recycled concrete pier body of the present invention includes a T-shaped pier body, and the T-shaped pier body is formed by welding four circular steel pipes and six rectangular steel plates (decorated plates), and the circular steel pipes are divided into main steel pipes 1 and auxiliary steel pipe 2 / 3, the main steel pipe 1 is located at the corner of the T-shaped pier body, each auxiliary steel pipe is welded with the double steel plate 4 and the main steel pipe 1 as the three limbs of the T-shaped pier body and the double steel plate 4 is connected with the auxiliary steel pipe Cut welding, the auxiliary steel pipe is located at the end of each limb; the interior of the steel pipe and the cell surrounded by the steel plate are welded with shear studs 5 and poured steel fiber micro-expansion recycled concrete 6.

[0020] Production process

[0021] The wall thickness of the selected circular steel pipe sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com