Engine case cover for forklift

An engine box, forklift technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of easy fracture, not very high strength, unable to protect the engine well, and achieve convenient operation and clear ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

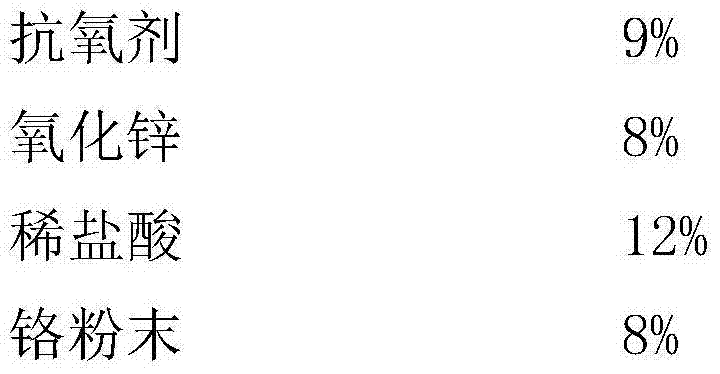

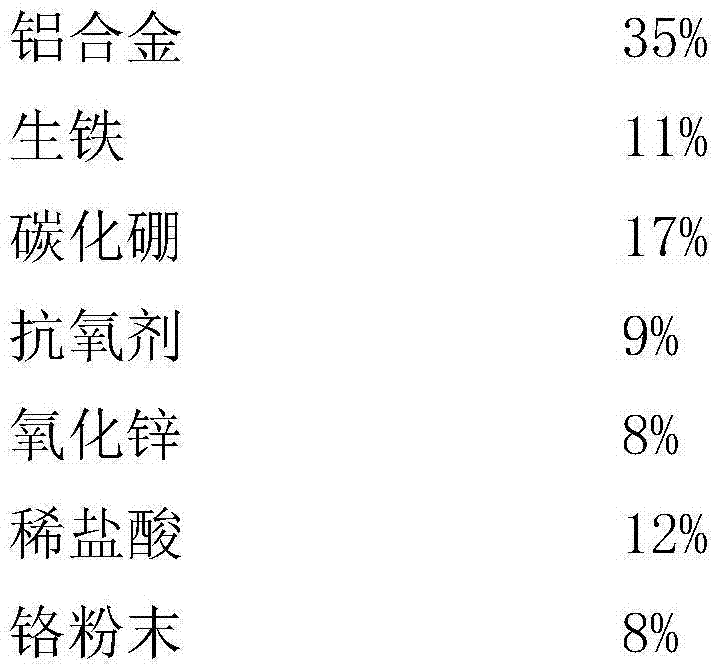

[0018] An engine case cover for a forklift, characterized in that it comprises the following components,

[0019]

[0020] The present invention also provides a method for preparing an engine case cover for a forklift, comprising the following steps,

[0021] Step 1. Melt aluminum in a high-temperature melting furnace at 710-790°C for 30-47 minutes, then take out the liquid and place it in a constant temperature furnace at 650-723°C to maintain the temperature;

[0022] Step 2: Put the pig iron in a melting furnace at 589-666°C to melt for 25-38 minutes, then take out the liquid and place it in another constant temperature furnace at 526-577°C to keep the temperature;

[0023] Step 3. Put the aluminum solution, zinc oxide, chromium powder, antioxidant, pig iron solution, boron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com