A monitoring and early warning method for filling body failure and instability precursor information

A filling body and precursor technology, which is applied to alarms, measuring devices, signal transmission systems, etc., can solve problems such as high filling costs, unclear stability status, and incomplete on-site monitoring data, and achieve simple construction and improved accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

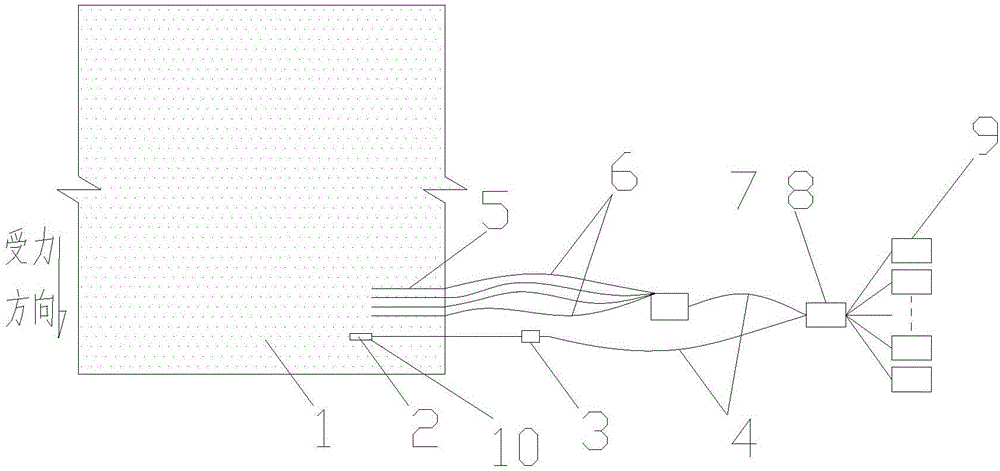

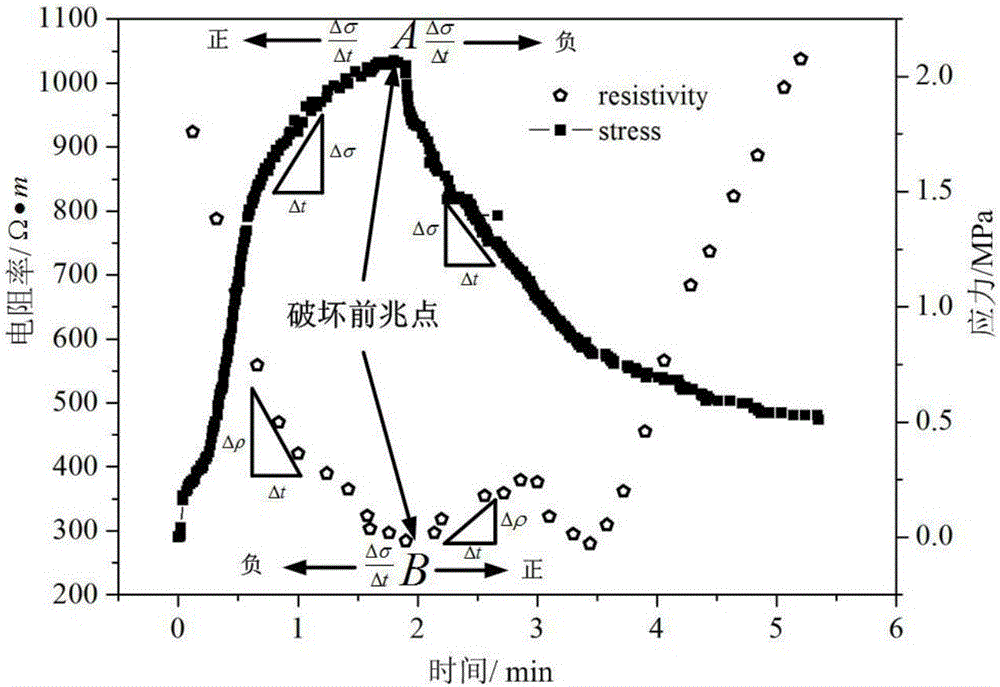

[0021] Combine figure 1 , figure 2 As shown, a kind of filling body damage and instability precursor information monitoring and early warning methods, including filling body 1, pressure pillow 2, digital display stress meter 3, optical fiber data line 4, needle electrode 5, copper wire 6, resistivity acquisition host 7 The data collection terminal 8, the user computer 9, the strain gauge 10, the strain gauge 10 installed on the pressure pillow 2 in the filling body 1 transmits the pressure signal through the oil pipe to the digital display stress gauge 3; the needle electrode 5 passes The copper wire 6 transmits the resistivity signal in the filling body 1 to the resistivity acquisition host 7; the stress data collected by the digital display stress meter 3 and the resistivity data collected by the resistivity acquisition host 7 are then transmitted through the optical fiber data line 4 To the data collection switchboard station 8, and finally through the data collection switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com