Three-dimensional grouting model test device and method

A technology of grouting model and test device, applied in the direction of material inspection products, etc., can solve problems such as not being able to guide the rational design of grouting engineering, affecting research progress, scientific understanding of difficult grouting process, etc., to achieve long-term stability. performance, advanced technical parameters, and the effect of enhancing scientific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

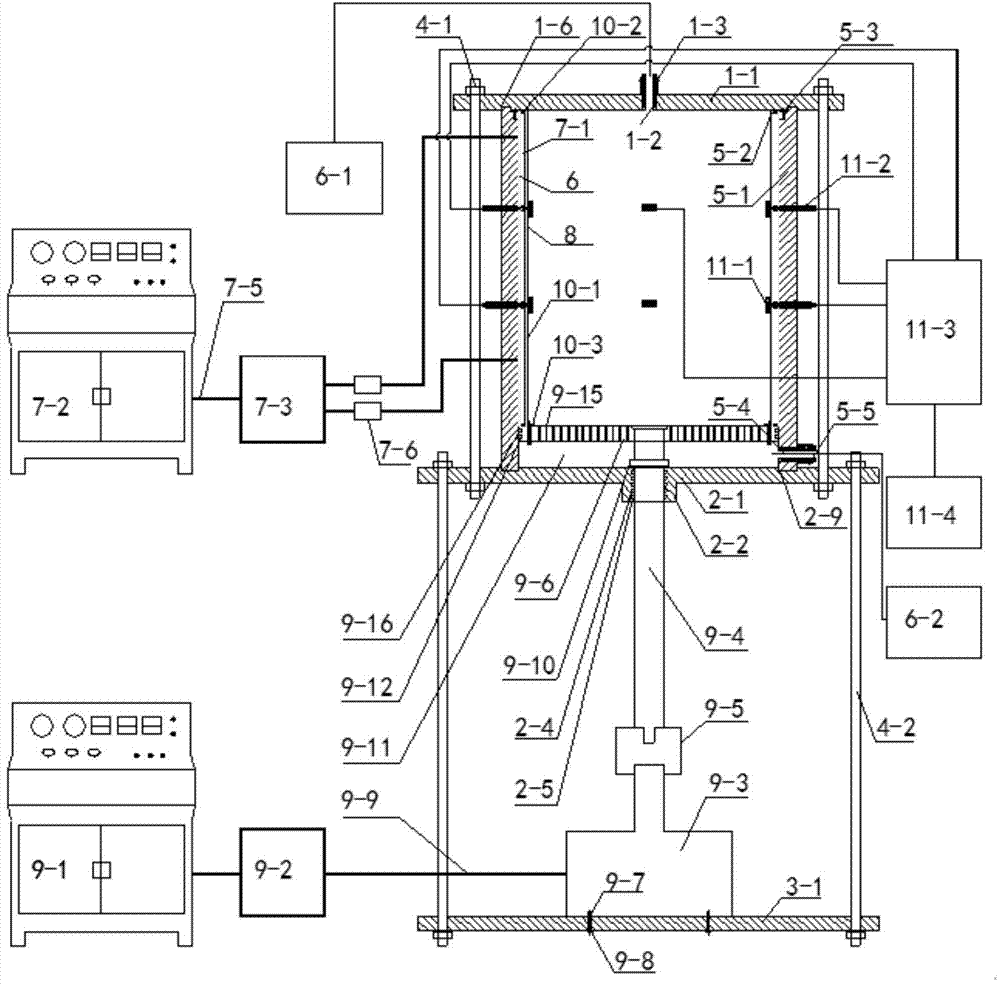

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

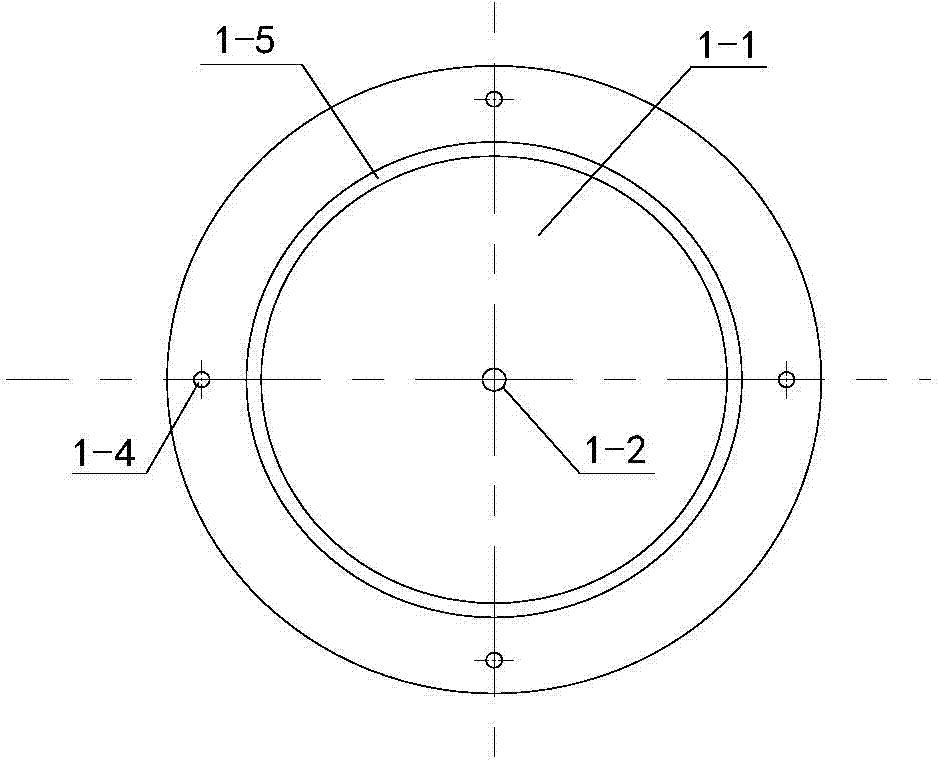

[0043] Such as figure 1 , figure 2 As shown, the first reaction force plate 1-1 is processed into a Φ660*25mm (diameter 660mm, height 25mm) disc made of high-strength alloy steel. Drill a Φ20mm grouting hole 1-2 at the center of the first reaction plate, cement the mining quick joint I 1-3, and connect the grouting equipment 6-1; drill 4 symmetrically distributed holes on the first reaction plate Φ590mm circle Φ20mm fixing hole I 1-4, so that the fastening screw I4-1 passes through; the lower surface of the first reaction force plate is processed with a Φ500*470*5mm annular groove I 1-5, and the built-in rubber gasket rubber gasket I 1- 6.

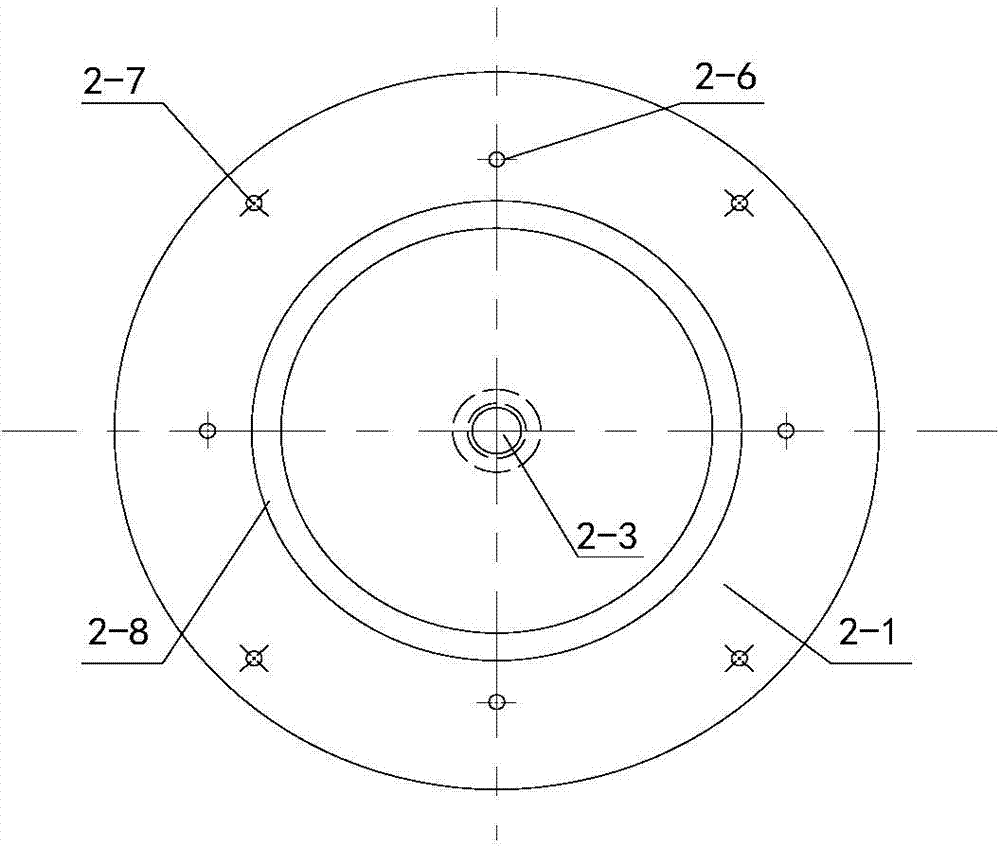

[0044] Such as figure 1 , image 3 As shown, the second reaction force plate 2-1 is processed into a Φ780*25mm disc made of high-strength alloy steel, and a Φ90*30mm cylindrical spacer 2-2 is welded on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com