A temperature flow rate control device and test method for transformer oil insulation thermal aging test

A flow rate control device, transformer oil technology, applied in the direction of testing dielectric strength, etc., can solve the problem of inability to realize oil temperature gradient change, etc., and achieve the effect of low cost and substantial accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In the following, a temperature flow rate control device for transformer oil insulation thermal aging test and a test method thereof according to the present invention will be further described in detail according to the drawings and specific embodiments.

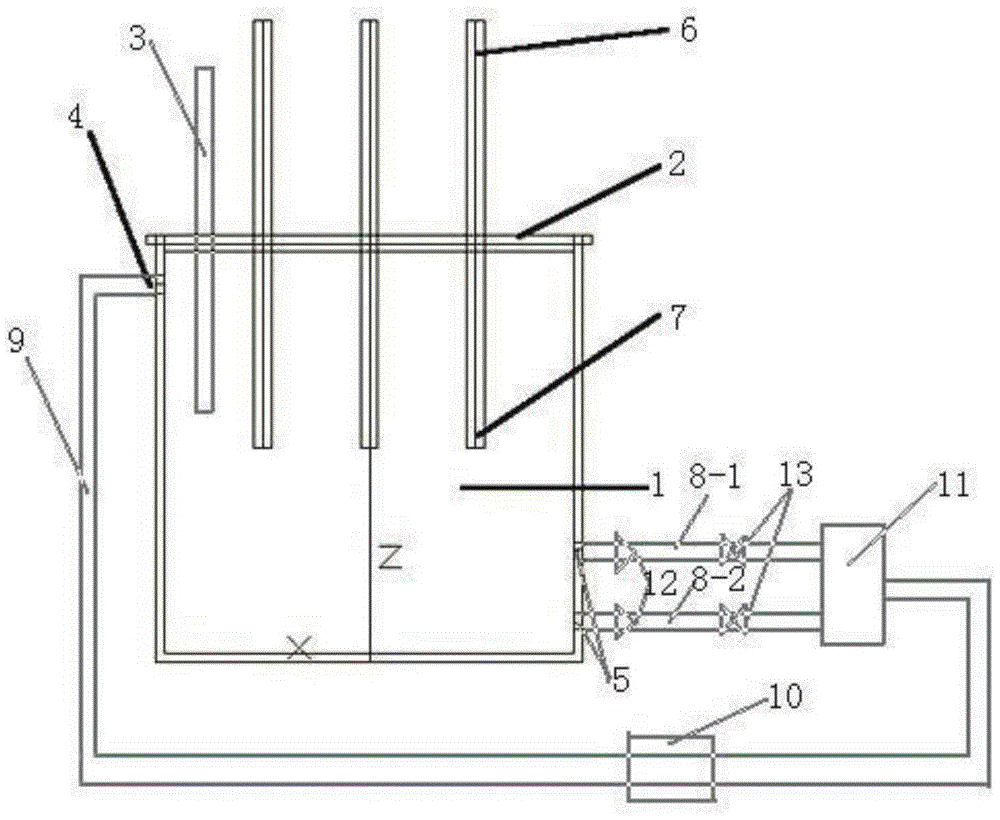

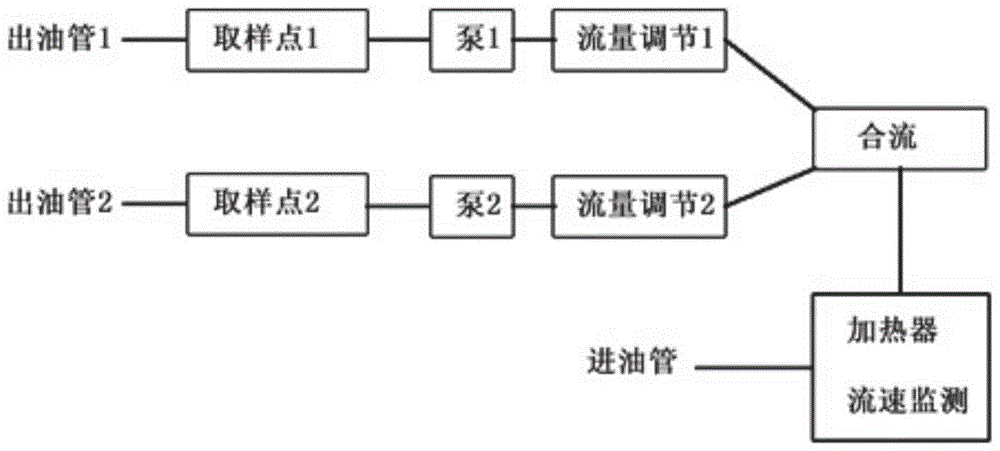

[0058] Such as figure 1 A temperature flow rate control device for thermal aging test of transformer oil insulation is shown, which is used to cooperate with quantitative research on thermal aging of transformer oil insulation, including cavity system and piping system;

[0059] The cavity system includes a cavity (1) for holding transformer oil, a cover (2) for sealing the cavity, and an electrochemical monitor (3);

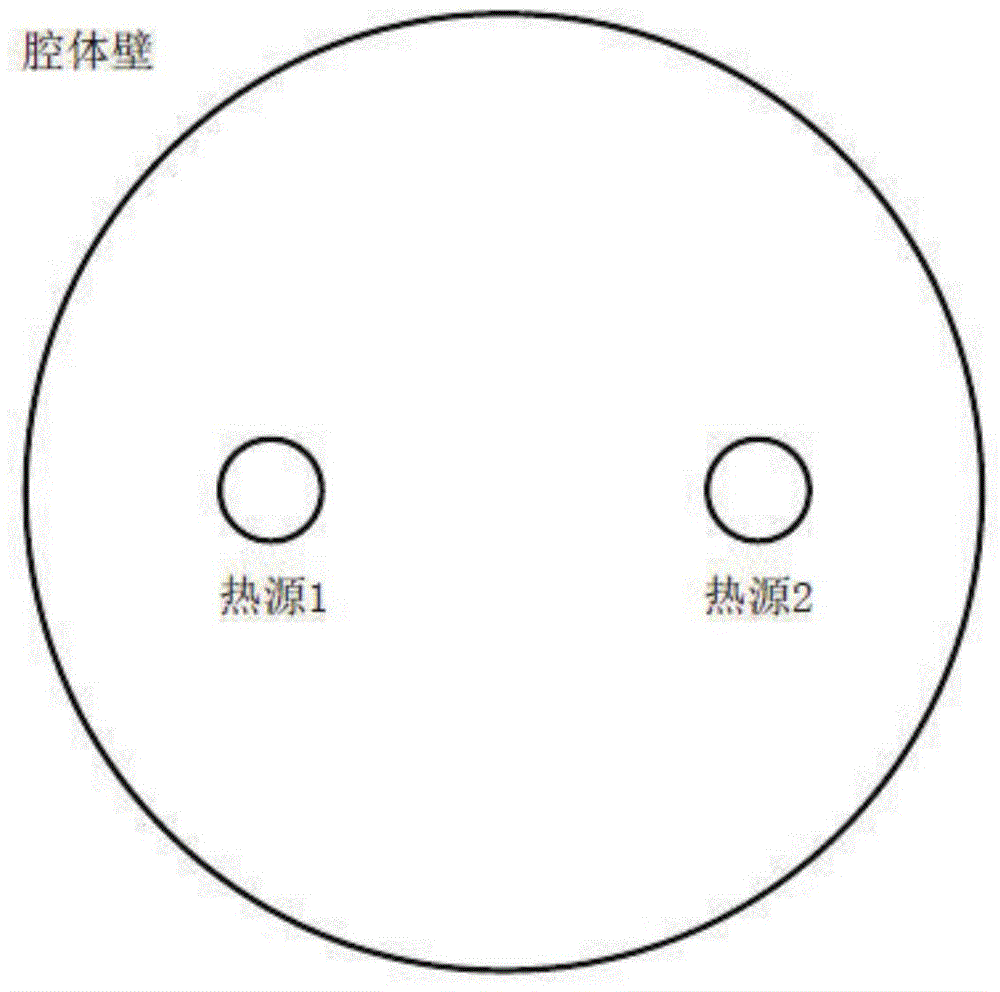

[0060] An oil inlet (4) and at least two oil outlets (5) are opened on the cavity, at least three openings are set on the sealing cavity cover, and the A temperature detector (6) and a simulated heat source (7) are built into the opening;

[0061] The electrochemical monitor is used to realize the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com