Single-mode fiber contact and manufacture method thereof

The technology of a single-mode optical fiber and its manufacturing method is applied in the field of single-mode optical fiber contacts and its manufacturing, and can solve problems such as easy burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

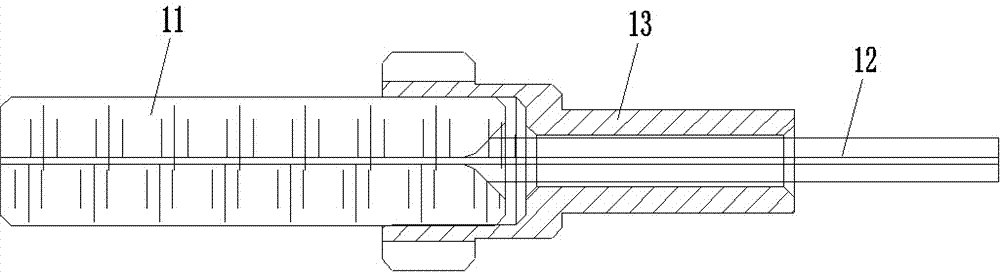

[0019] Examples of single-mode fiber optic contacts, such as Figure 1-2 As shown, the single-mode optical fiber contact piece includes a ferrule 11 and a single-mode optical fiber 12 passing through the ferrule 11 .

[0020] In this embodiment, the ferrule 11 is made of a ceramic ferrule and a tubular handle 13 is fixed at the tail. Its structure is the prior art, so it will not be repeated here.

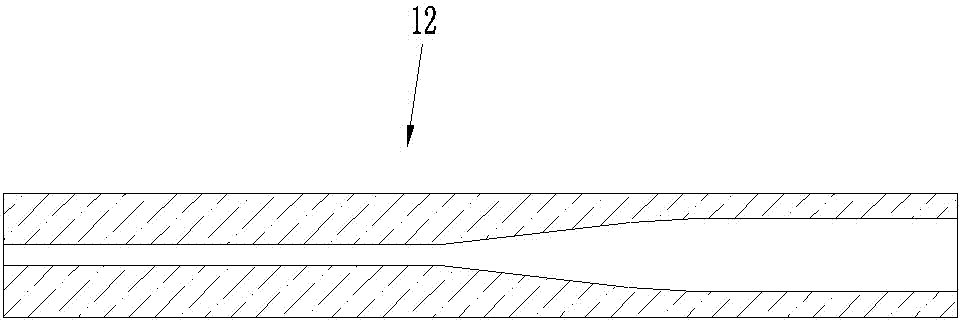

[0021] The single-mode fiber 12 uses a Geo 2 Dopant optical fiber, one end of the single-mode optical fiber 12 that penetrates the ferrule is a thermal diffusion optical fiber formed by thermal diffusion. After thermal diffusion, the Ge atoms contained in the Geo2 dopant in the single-mode optical fiber 12 diffuse, and its The refractive index distribution changes along the fiber axis, the mode field diameter is increased, and the core diameter can be changed from the original 9 microns to 55 microns, so it can be used to transmit high-power optical signals. When transmitting opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com