A usb3.0 type optical fiber connector connection assembly

A technology of USB3.0 and fiber optic connectors, applied in optical components, light guides, optics, etc., can solve the problems of small joint bearing force and clamping force, affecting optical fiber connection performance, affecting transmission performance, etc., and achieves high tensile strength , Ensure long-term stable use effect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described and illustrated below in conjunction with the accompanying drawings and embodiments.

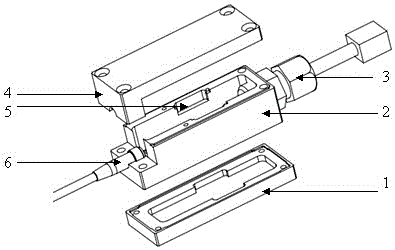

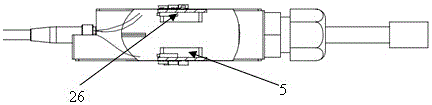

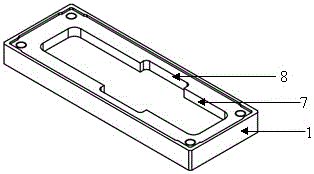

[0035] It includes a connector package, which includes an upper case cover 4, an intermediate case 2, and a base 1 that are stacked and connected up and down. The entire package is rectangular, and the base is long and narrow. An open cavity 7, the middle upper end of the cavity is provided with a lower chip fixing position 8, the upper end surface of the base is provided with a spigot along the periphery, the upper end of the base is matched with the intermediate housing, and the intermediate housing 2 is also narrow and long , there is a cavity that penetrates up and down in the housing, the cavity corresponds to the cavity of the base, and the lower chip fixing position 5a is set at the lower end of the housing corresponding to the lower chip fixing position of the base, which can be used to fix a photoelectric conversion chip 26. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com