Laminated busbar for photovoltaic grid-connected inverter

A technology of stacking busbars and inverters, which is applied in photovoltaic power generation, converting equipment structural components, converting AC power input into DC power output, etc. and cost increase, to achieve the effect of easy unified and standardized production, wide application range and excellent use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

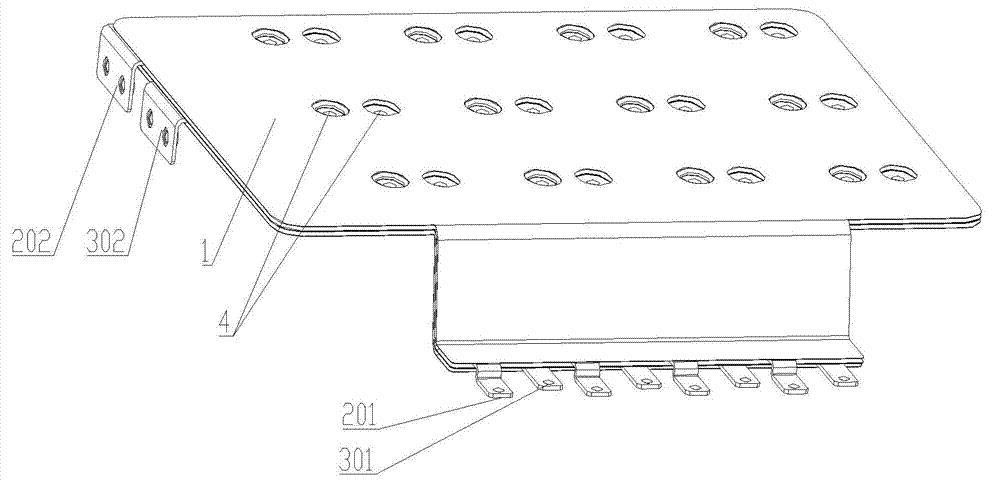

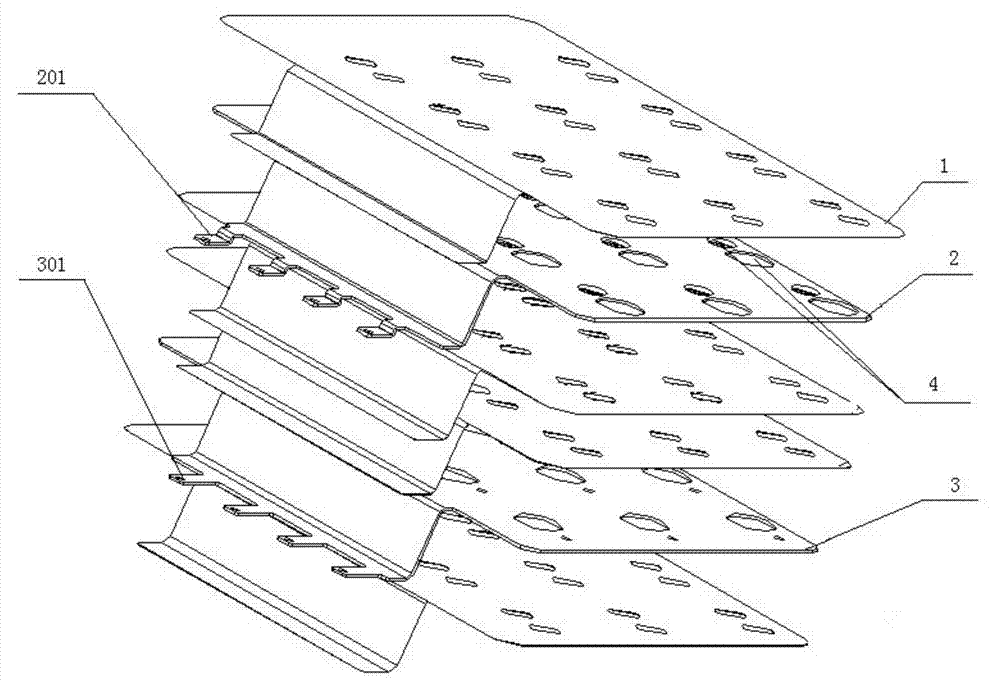

[0043] Such as figure 1 As shown, the present invention includes an insulating and heat-conducting layer 1 and a red copper copper plate. The red copper copper plate is rectangular and has two layers. The two sides of each layer are respectively provided with an insulating and heat-conducting layer 1. The insulating and heat-conducting layer 1 is fixedly connected to the red copper copper plate. Together, they form a flat whole without gaps. On the copper plate and the insulating and heat-conducting layer 1, positive and negative capacitor connection holes 4 are respectively provided at corresponding intervals. One side of the copper plate is provided with a positive and negative terminal, and the adjacent side Side intervals are provided with IGBT positive and negative terminals.

[0044] The insulating and heat-conducting layer 1 is PET insulating paper. The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com