Packaging structure of multi-chip wide bandgap power module based on conductive metal clip interconnection

A conductive metal and power module technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the service life of power modules, increasing the volume of power modules, and accelerating the failure of power modules, so as to reduce the possibility of failure, The effect of reducing module size and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

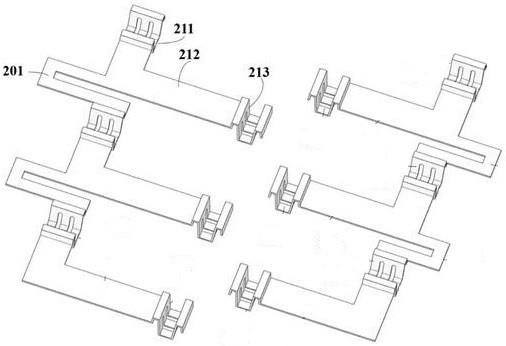

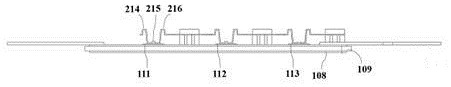

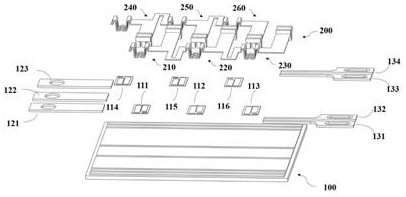

[0061] see figure 1 , figure 2 and image 3 , the packaging structure of this embodiment is mainly composed of 6 power electronic power semiconductor chips, 3 power substrates, 3 power terminals, 4 drive terminals and 2 conductive metal clips;

[0062] The six power electronic power semiconductor chips are specifically a semiconductor chip 111, a semiconductor chip 112, a semiconductor chip 113, a semiconductor chip 114, a semiconductor chip 115, and a semiconductor chip 116;

[0063] The three power substrates are specifically the lower surface conductive metal substrate 108, the insulating dielectric substrate 109 and the upper surface conductive metal substrate;

[0064] The three power terminals are specifically DC power terminal positive pole 121, DC power terminal negative pole 122 and AC power terminal 123;

[0065] The four drive terminals are specifically the source drive terminal 131 of the upper arm using the Kelvin connection method, the gate drive terminal 132...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com