High-performance microstrip array antenna

A microstrip array, high-performance technology, applied in antennas, antenna arrays, antenna grounding devices, etc., can solve problems such as poor antenna impedance matching characteristics, inability to obtain power transmission, and damage to power distribution networks, so as to eliminate parasitic inductive reactance, Improving impedance matching characteristics, reducing feeder loss and spurious radiation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

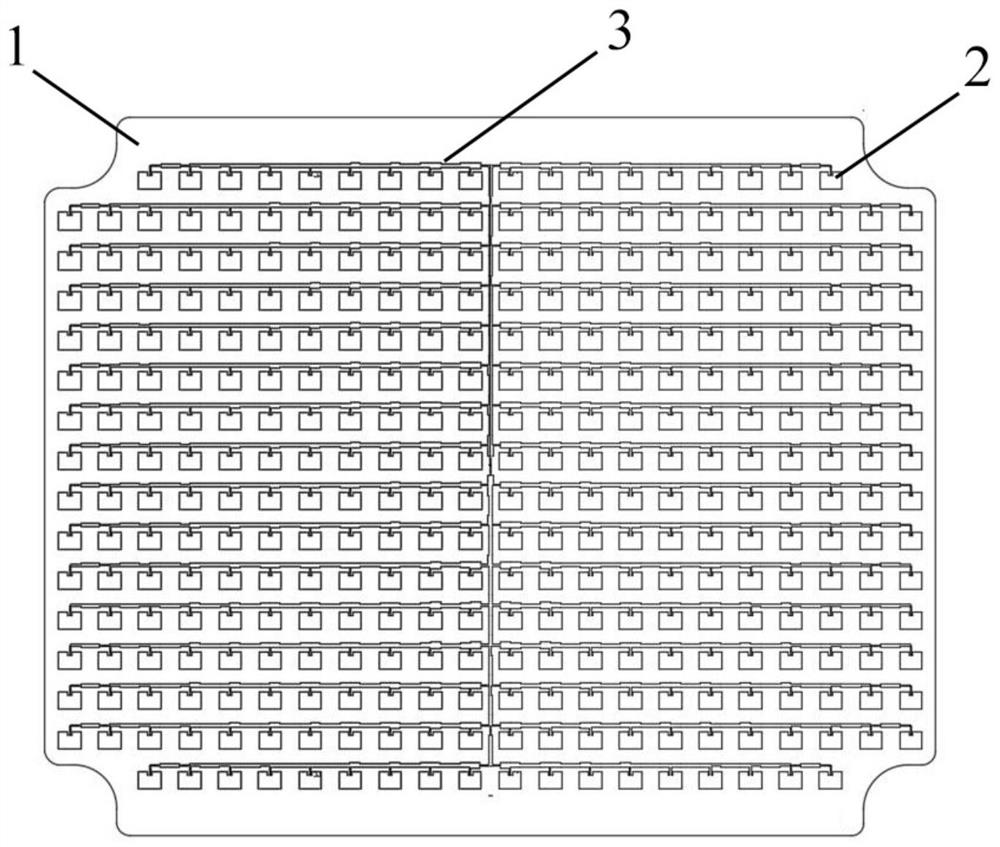

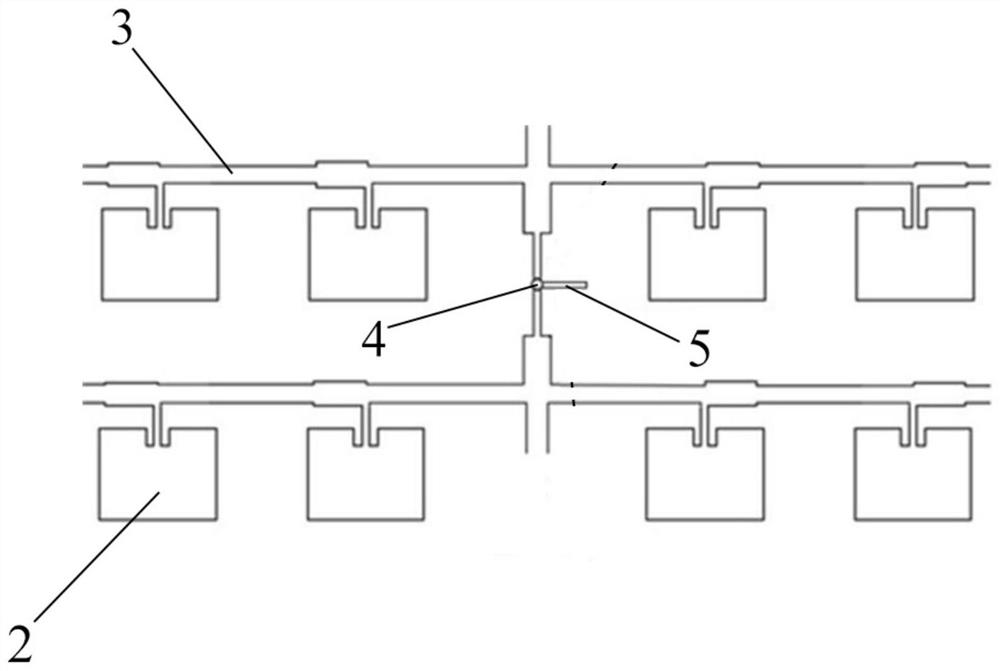

[0026] see Figure 1-2 As shown, a high-performance microstrip array antenna includes a substrate 1. The substrate 1 includes an upper substrate and a lower substrate disposed on the bottom surface of the upper substrate. The bottom surface of the lower substrate is provided with a metal ground layer. The structure of the substrate is a prior art and will not be repeated here.

[0027] The top surface of the upper substrate is arranged in a rectangular array with a number of microstrip radiation patches 2 (radiation units), that is, the array spacing in the horizontal direction is the same, and the array spacing in the vertical direction is the same, and the number of microstrip radiation patches 2 arrays in the horizontal direction is the same as that in the vertical direction. are even numbers. It should be noted that, during actual production, the number of arrays in the horizontal direction and the number of arrays in the vertical direction of the microstrip radiation pat...

Embodiment 2

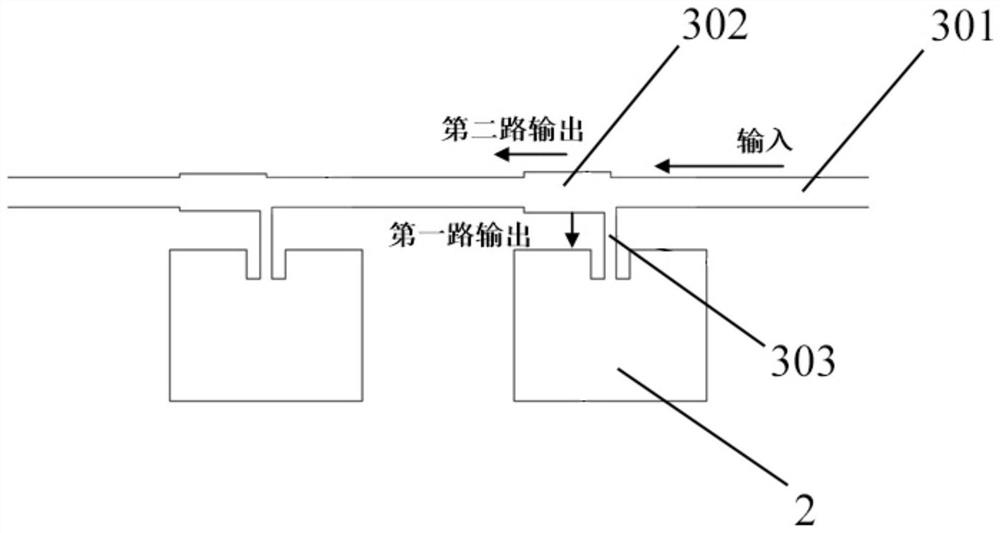

[0035] see Figure 1-4 As shown, on the basis of Example 1, the microstrip radiation patch is rectangular 2, and the horizontal direction and vertical direction of the rectangular array of microstrip radiation patches 2 are respectively consistent with the length direction and width direction of the microstrip radiation patch 2. Optionally, the substrate 1 is rectangular, and the horizontal direction and vertical direction of the rectangular array of microstrip radiation patches 2 are respectively consistent with the length direction and width direction of the substrate 1 .

[0036] In the rectangular array of microstrip radiation patches 2, the spacing between adjacent microstrip radiation patches 2 in the horizontal direction is equal to the spacing between adjacent microstrip radiation patches 2 in the vertical direction, ensuring that each single microstrip radiation patch 2 There is a 360° phase difference at the center frequency point.

[0037] The power distribution ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com