Comprehensive crop straw harvesting machine

A crop straw and harvester technology, which is applied to agricultural machinery and tools, agriculture, loaders, etc., can solve the problems that affect the collection and comprehensive utilization of crop straw, the high cost of straw collection and processing, and low operating efficiency, so as to promote The effects of collection and comprehensive utilization, improvement of equipment operation efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

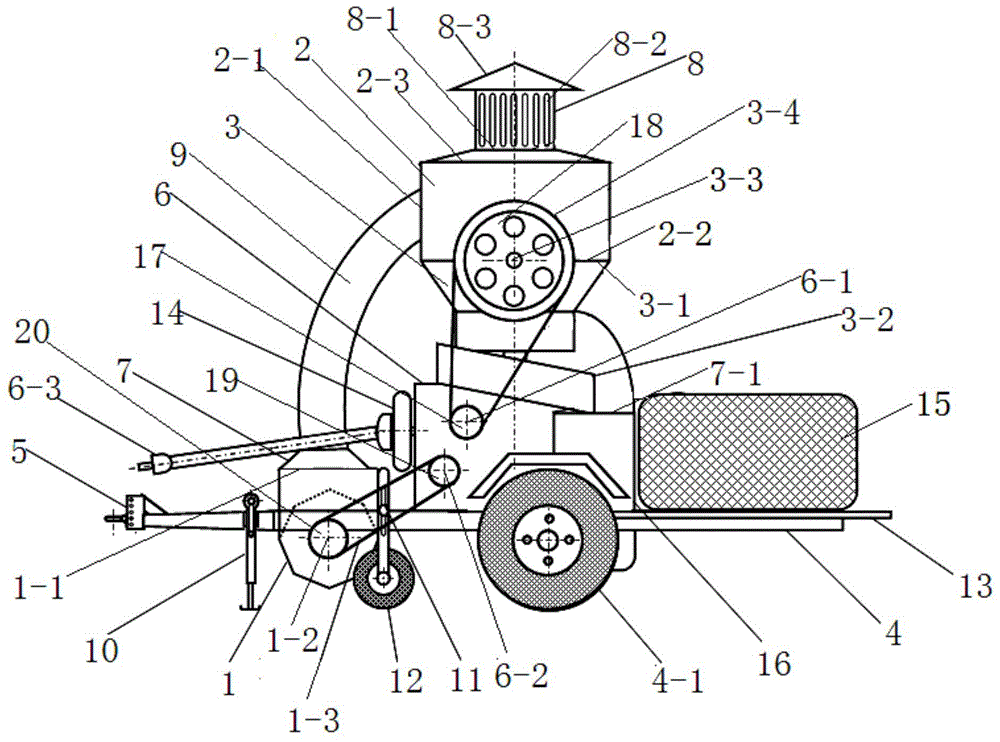

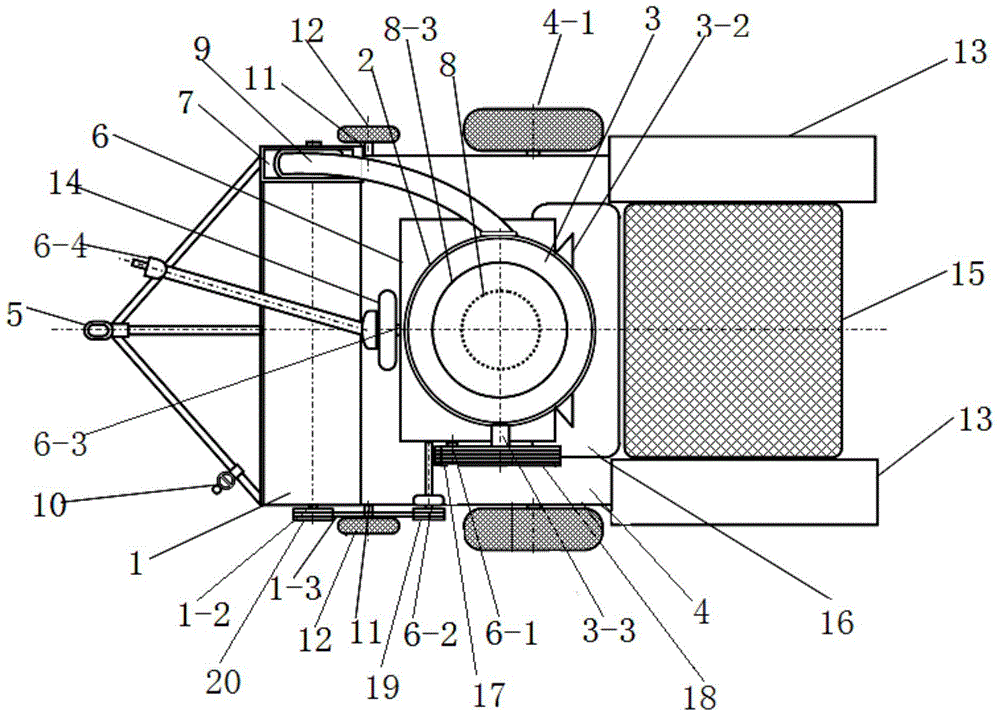

[0022] like Figure 1~2 The crop straw comprehensive harvester shown includes a tractor, a picking and crushing device 1, a rotating airflow separation bin 2, a forming unit 3, a transmission gearbox 6 and a harvester chassis 4, the forming unit 3 is a ring die briquette forming unit, and the harvester chassis 4 both sides are provided with traveling wheel 4-1, picks up crushing device 1 and hangs on harvester chassis 4 front parts, picks up the both sides of crushing device 1 and is respectively connected with profiling wheel bracket 11, is connected with picking up imitation wheel bracket 11 on the profiling wheel bracket 11. Shaped wheel 12, picking up profiling wheel 12 drives picking up and crushing device 1 to change with the change of ground heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com