Spice for marinating eggs and method for marinating eggs

A technology for eggs and brine, applied in application, food preparation, food science and other directions, can solve the problems of thin taste, low production efficiency, water loss, etc., and achieve the effect of shortening processing time, improving processing efficiency and preventing water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

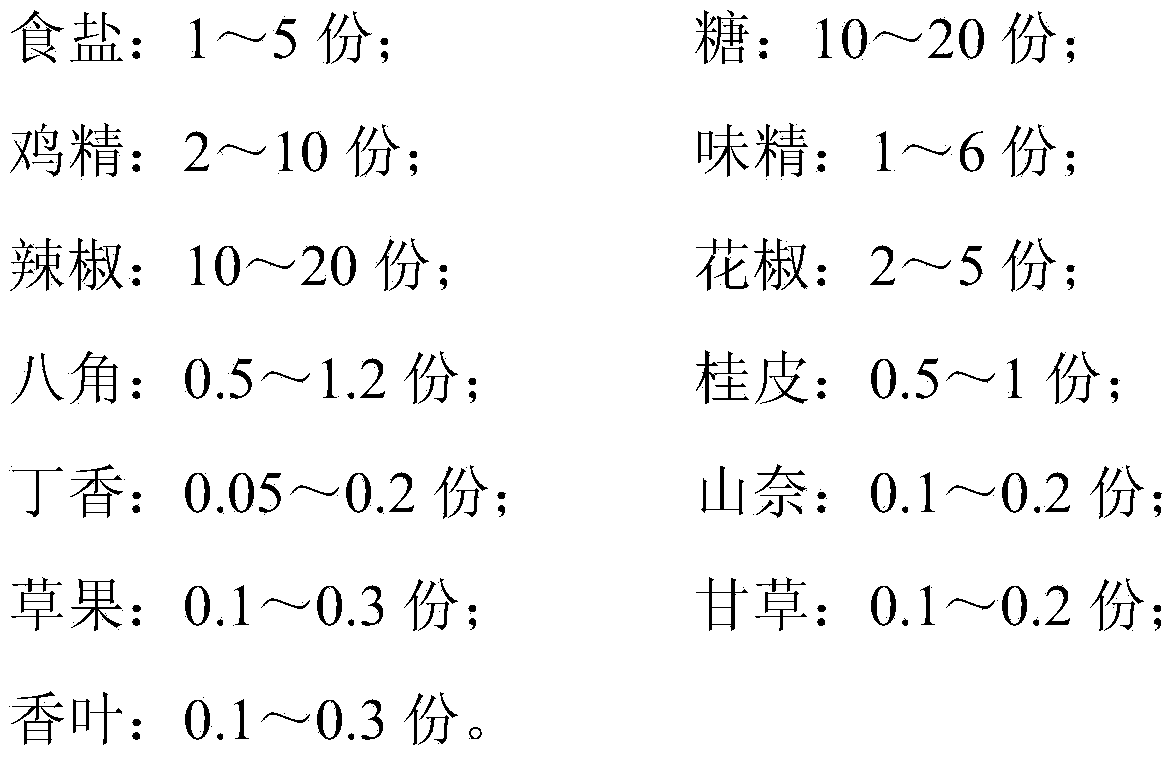

[0047] In terms of parts by mass, the halogen material made of the following raw materials is selected for use:

[0048]

[0049] The method for marinating eggs with the marinated material comprises the following steps:

[0050] Step 101: Select eggs that are 4 days old from the laying date, and disinfect the eggs to obtain disinfected eggs.

[0051] Step 102: Put the sterilized eggs into the jacketed pot, pour water into the jacketed pot until 5cm of the sterilized eggs are covered, the temperature of the water is 15°C, heat until the water boils, cook for 5 minutes until the eggs are cooked, then pick up the boiled eggs and put into water with a temperature of 15° C., store for 5 minutes until the temperature of the boiled eggs is lower than 25° C., and then remove the shells to obtain shellless eggs.

[0052] Step 103: Select shellless eggs with no damage on the surface, put them into high-temperature oil at 150° C., so that the oil surface is submerged by 0.5 cm of the...

Embodiment 2

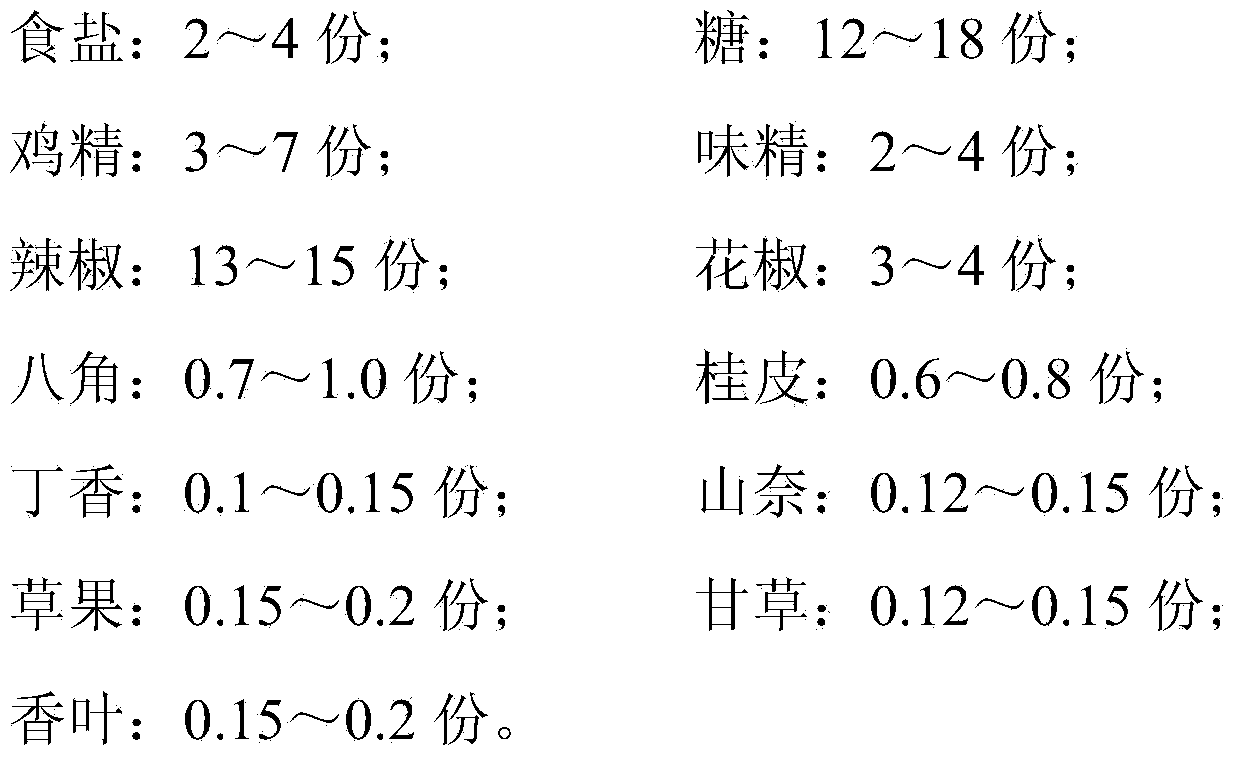

[0058] In terms of parts by mass, the halogen material made of the following raw materials is selected for use:

[0059]

[0060] The method for marinating goose eggs with the stewed material comprises the following steps:

[0061] Step 201: Select goose eggs 6 days from the laying date, and disinfect the goose eggs to obtain sterilized goose eggs.

[0062] Step 202: Put the sterilized goose eggs into the jacketed pot, pour water into the jacketed pot until 7cm of the sterilized goose eggs are covered, the temperature of the water is 20°C, heat until the water boils, cook for 8 minutes, and then remove the boiled goose eggs Take it up and put it into water at a temperature of 20°C, store it for 8 minutes until the temperature of the goose eggs is lower than 25°C, and then remove the shells to obtain shellless goose eggs.

[0063] Step 203: Select shellless goose eggs with no damage on the surface, put them into high-temperature oil at 175°C, so that the oil surface is subm...

Embodiment 3

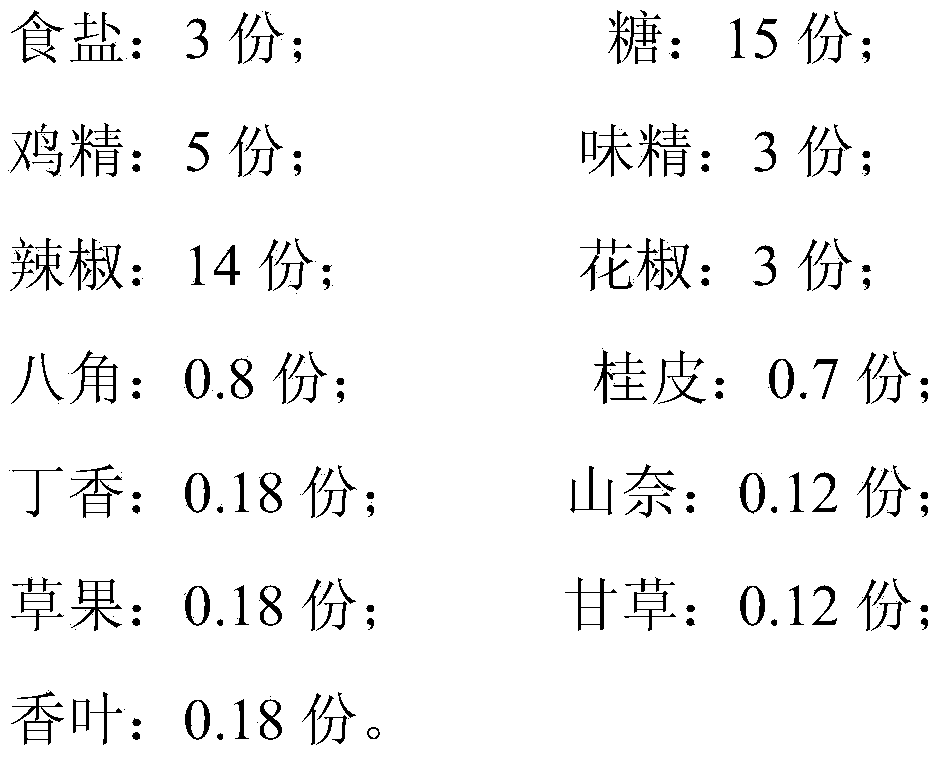

[0069] In terms of parts by mass, the halogen material made of the following raw materials is selected for use:

[0070]

[0071] The method for marinating quail eggs with the stewed material comprises the following steps:

[0072] Step 301: Select quail eggs 8 days from the egg-laying day, and disinfect the quail eggs to obtain disinfected quail eggs.

[0073] Step 302: Put the sterilized quail eggs into the jacketed pot, pour water into the jacketed pot until 10 cm of the sterilized quail eggs are covered, the temperature of the water is 25°C, heat the water to boil, cook for 10 minutes, and then remove the boiled quail eggs Take it up and put it into water with a temperature of 25°C, store it for 10 minutes until the temperature of the quail eggs is lower than 25°C, and then remove the shells to obtain shellless quail eggs.

[0074] Step 303: Select shellless quail eggs with no damage on the surface, put them into high-temperature oil at 200°C, so that the oil surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com