A guide vane angle adjustment system related to a powder classifier

A guide vane and angle adjustment technology, which is applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of laborious, time-consuming manual adjustment of angles, etc., to save labor costs and shorten debugging Time, to achieve the effect of real-time adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

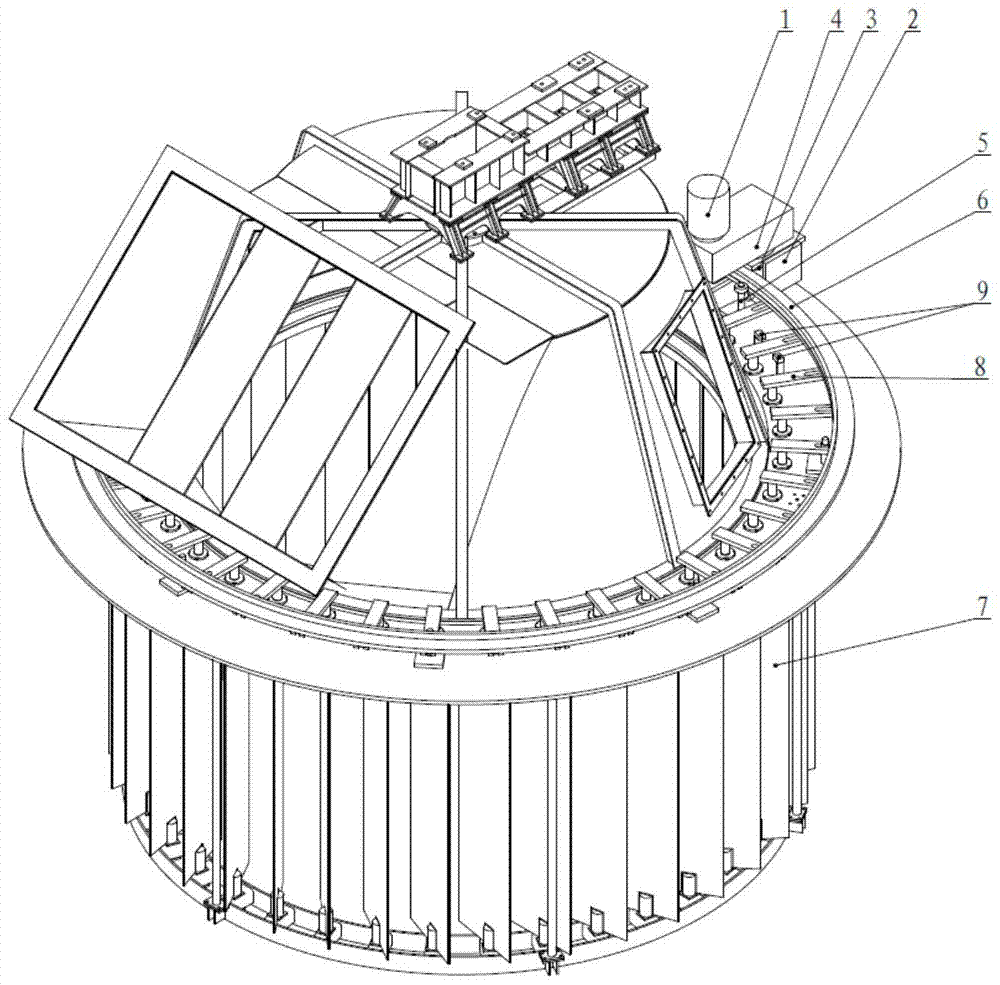

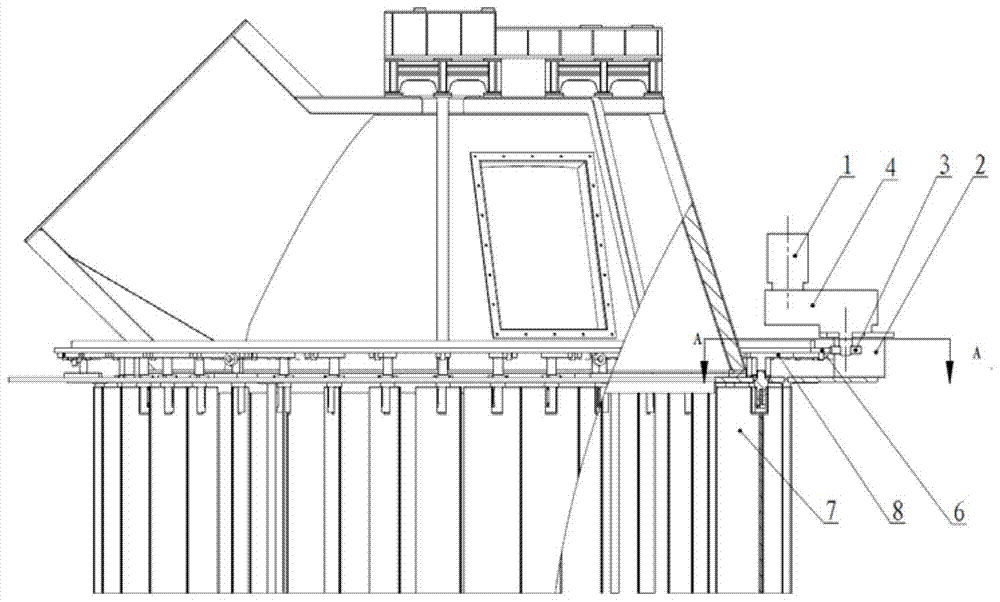

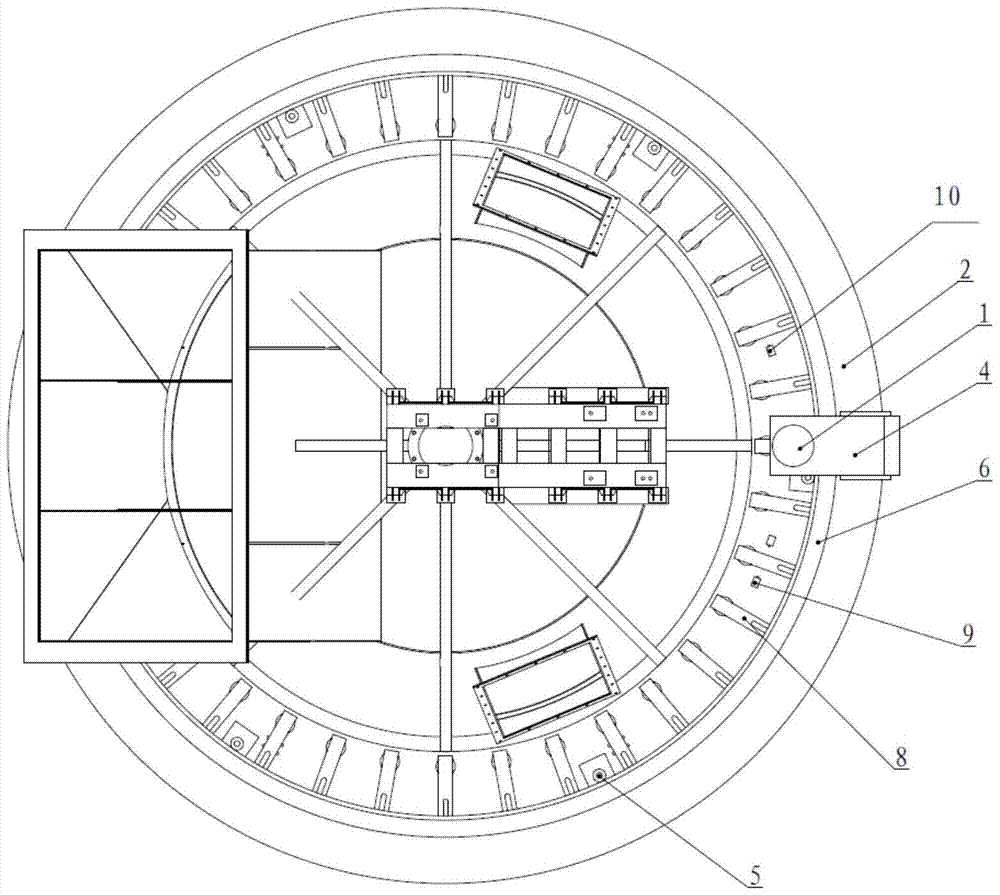

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , including stepper motor 1 with brake disc, powder classifier housing 2, transmission gear 3, reducer 4, bracket 5, large ring gear 6, guide vane 7, transmission arm 8, limit switch 9, displacement sensor 10. There is a flange on the lower part of the stepping motor 1 with a brake disc, and the powder separator housing 2 is installed on the flange. The output end of the stepping motor 1 is provided with a reducer 4 with a transmission gear 3, and the powder separator housing The large ring gear 6 supported by the bracket 5 on the 2 is paired with the transmission gear 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com