Cutting Technology of Aluminum Profile Electronic Radiator and Its Stamping Cutting Die

A technology of aluminum profiles and radiators, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting raw materials, burrs easily appearing in cutting workpiece sections, and debris affecting product quality, so as to protect the environment and improve work Environmental quality, the effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

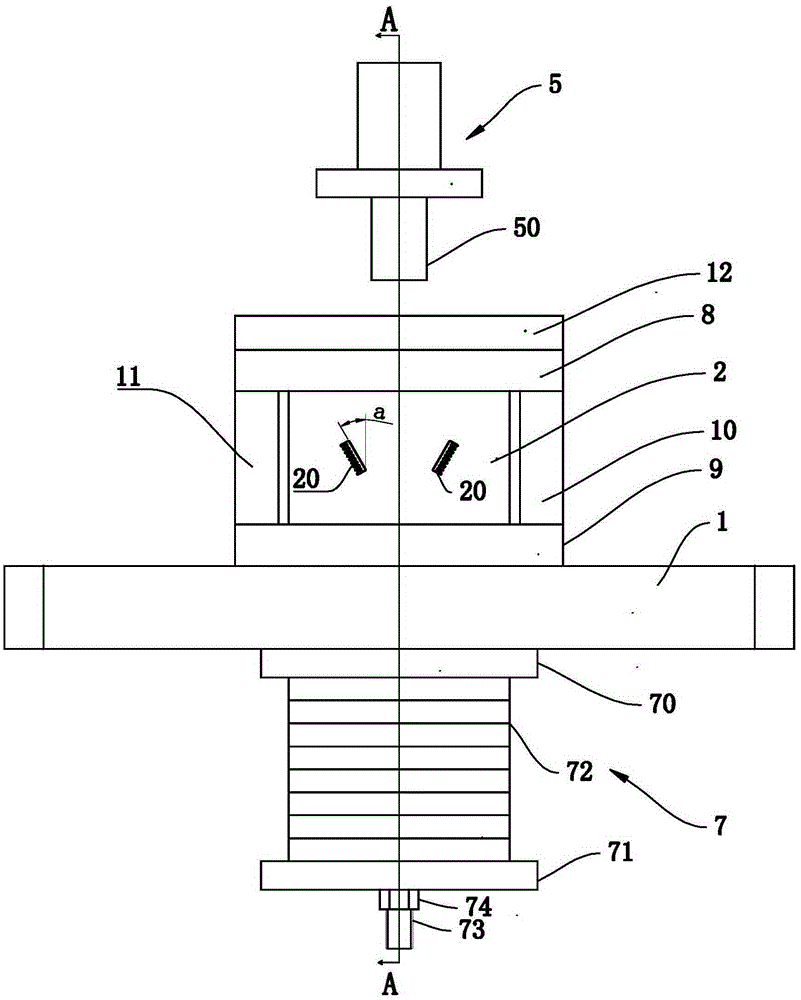

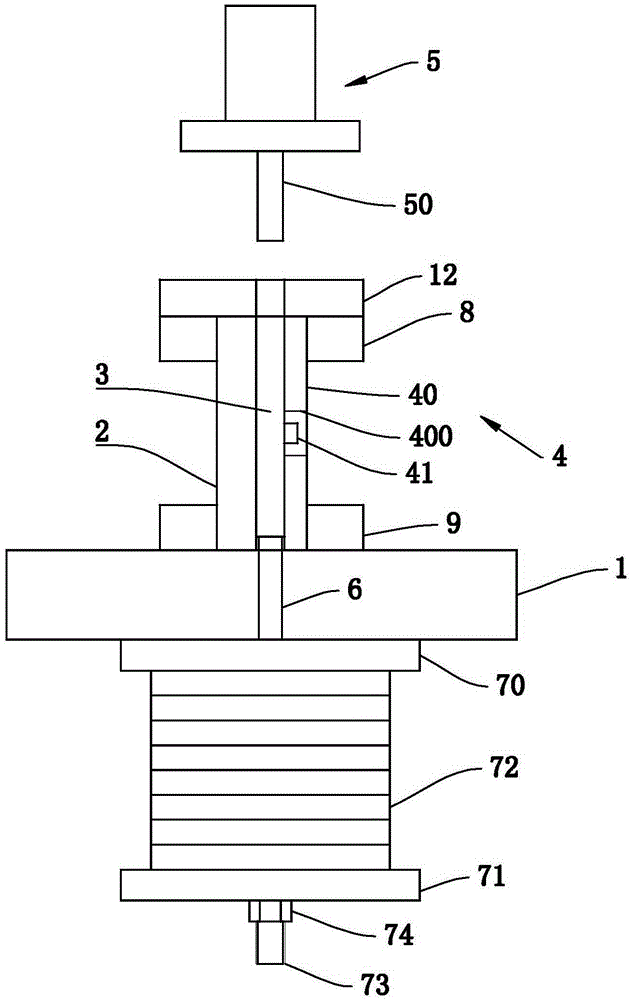

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] A cutting process for an aluminum profile electronic radiator, comprising the following steps:

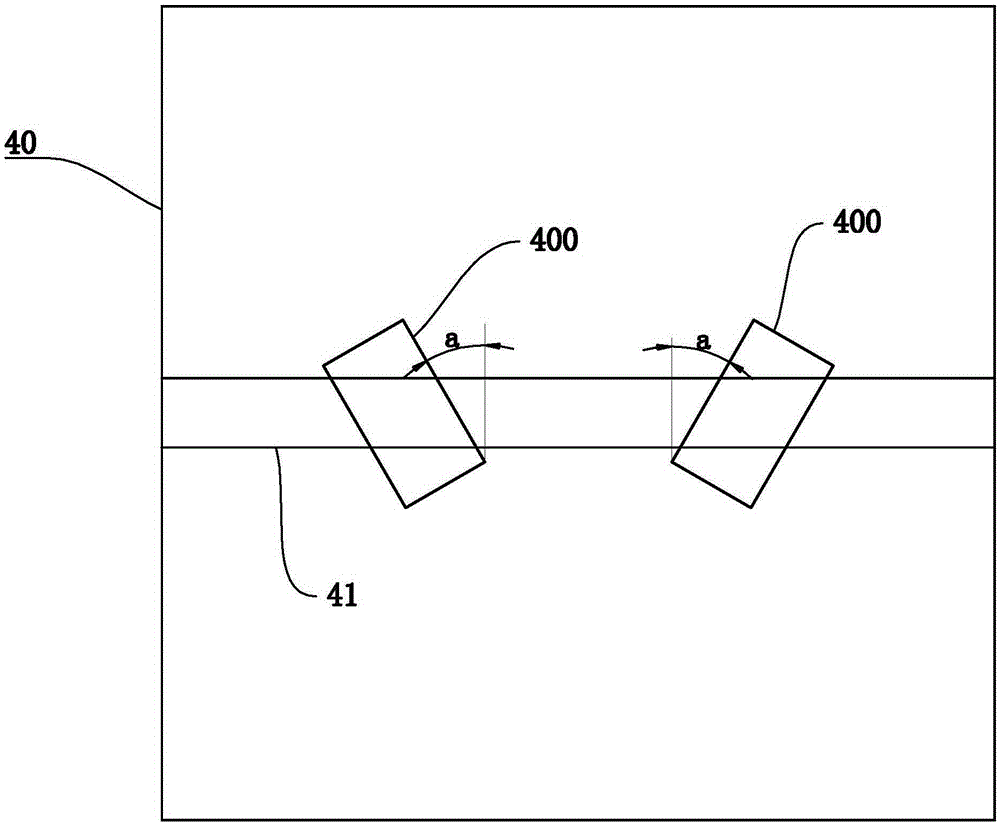

[0037] a. Profile positioning: Insert one end face of the profile into the insertion cavity on the fixed die 2 and the movable die 3 of the stamping cutting die in sequence until the end face of the profile pushes against the positioning device 4;

[0038] b. Cut off the profile positioned in step a: Start the punching machine so that the punch 50 of the punching machine punches the movable die 3, and relative motion occurs between the movable die 3 and the fixed die 2. At this time, the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com