Car body structure of light weight railway vehicle

A rail vehicle and car body structure technology, applied in the direction of railway car body, railway car body parts, railway transportation, etc., can solve the problems of not meeting social development and market demand, not being able to play a load-bearing role, and redundant strength, etc., to achieve Good economic and social benefits, light weight, and the effect of improving load-bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

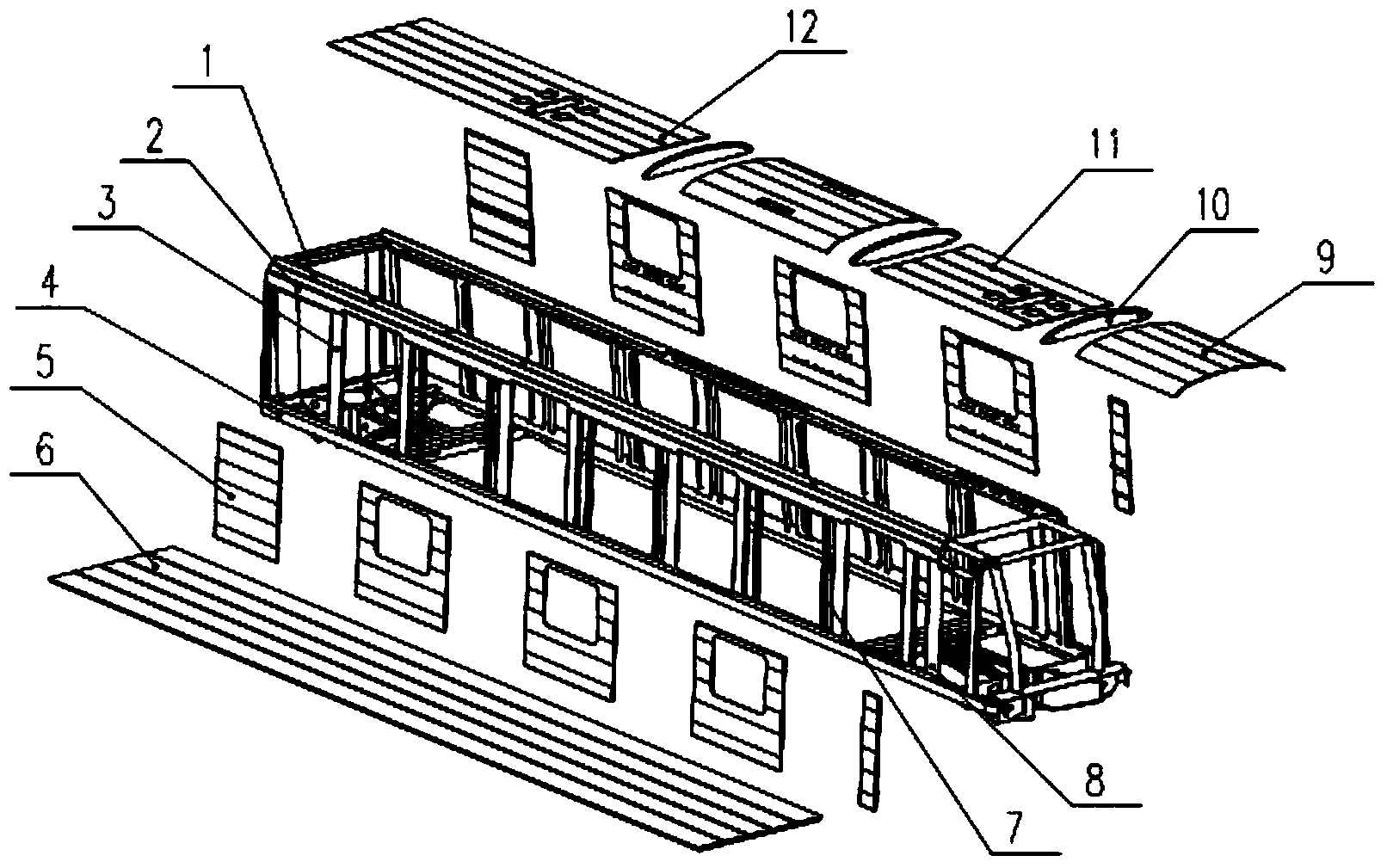

[0030] The present invention will be further elaborated below by taking the aluminum alloy car body structure of a subway vehicle as an example in conjunction with the accompanying drawings and embodiments.

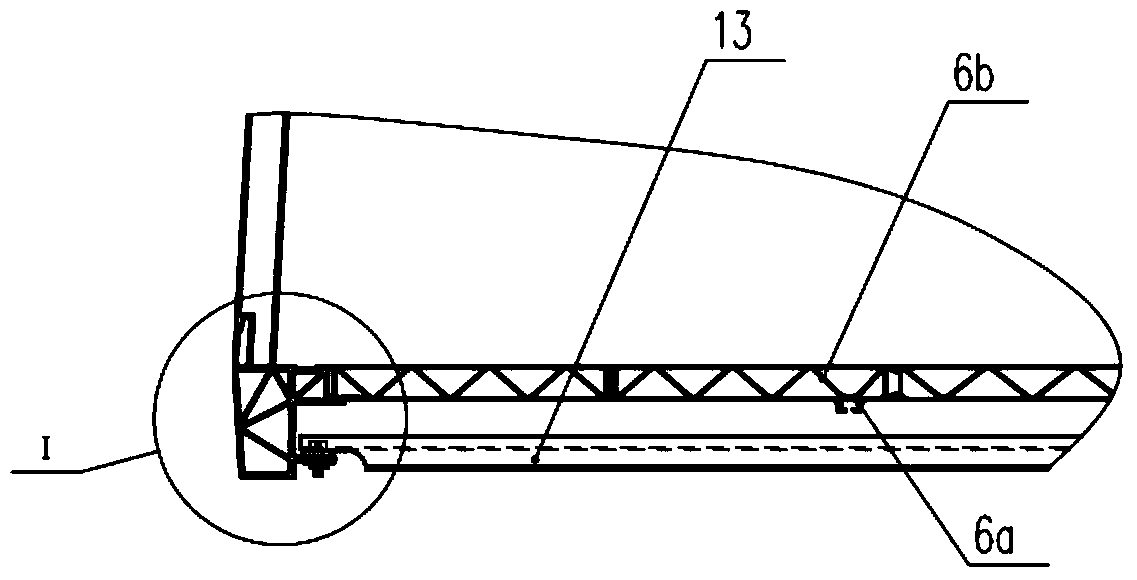

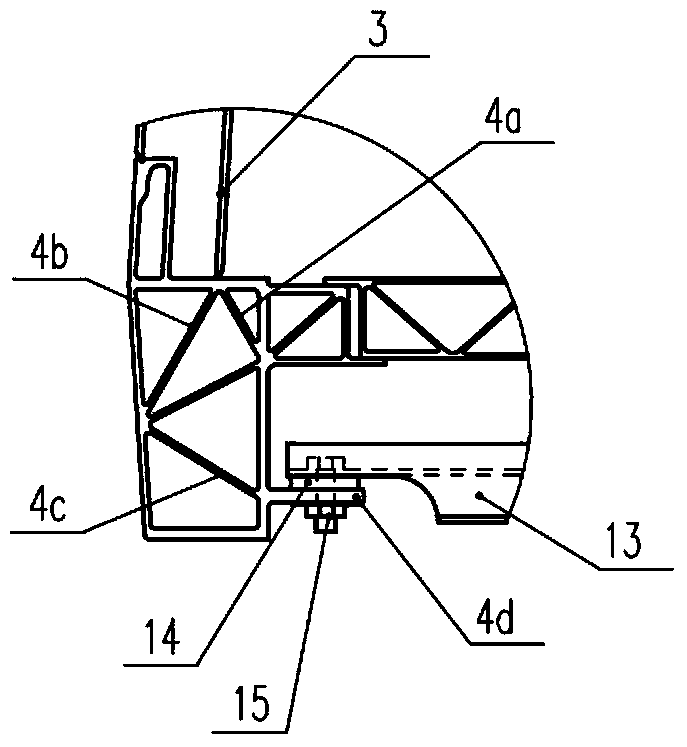

[0031] A kind of aluminum alloy car body structure of a subway vehicle, such as figure 1 Shown: the main load-bearing beam of the upper part of the car body is composed of the long roof beam 1 and the roof side beam 2, the underframe side beam 4 is the main load-bearing beam of the lower part of the car body, the passenger compartment door column 3, and the side wall support beam 7 The upper load-bearing beam and the lower load-bearing beam are connected with the driver's cab door column 8 to form a frame structure. The frame, the end structure of the underframe, the frame of the driver's cab, and the frame of the end wall are formed by arc welding to bear the main longitudinal force and vertical force of the car body. skeleton structure. The arc roof 9 between the two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com