Control method for preventing hydrogenation tail gas blast in anthraquinone method preparation of hydrogen peroxide

A control method and technology of hydrogen peroxide, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of low safety factor, etc. The effect of ensuring safety and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

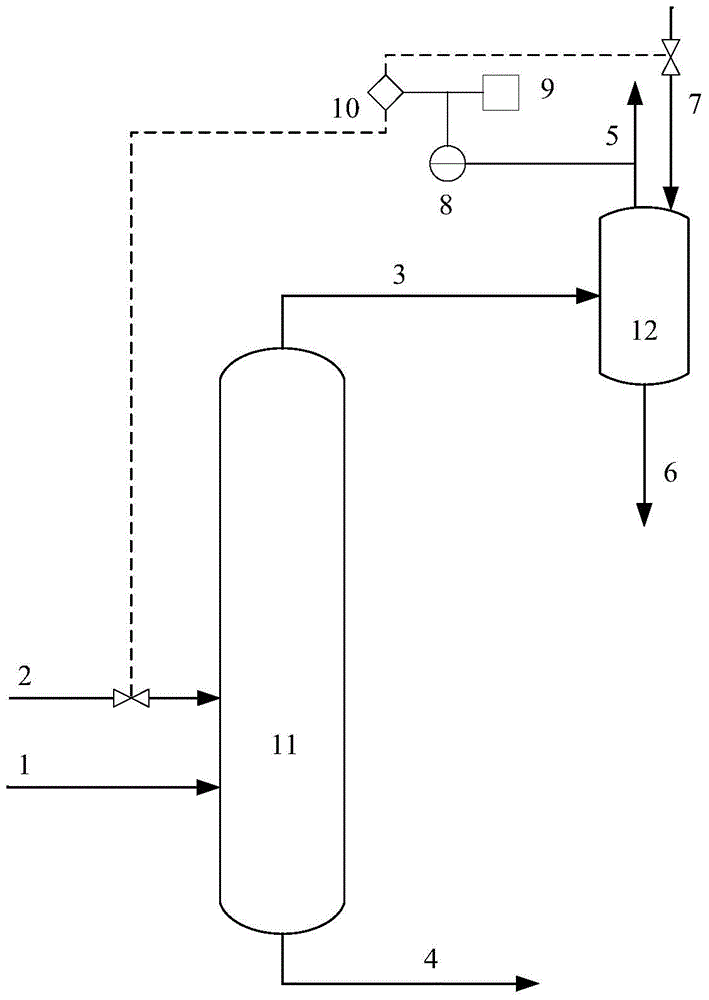

[0013] Such as figure 1 In the process flow shown, the outlet pipeline at the top of the hydrogenation reactor is connected to the gas-liquid separator, and the gas-phase outlet pipeline at the top of the gas-liquid separator is equipped with an oxygen content online detector, and an alarm value and an interlock value are set; The content on-line detector uses a thermomagnetic method to measure the oxygen content. When the oxygen content of the gas phase outlet at the top of the gas-liquid separator exceeds the alarm value (0.5%), reduce or cut off the hydrogenation reactor working liquid feed; when the oxygen content of the gas phase outlet at the top of the gas-liquid separator exceeds the interlock value (2.0%) , cut off the hydrogenation reactor working fluid feed, and add nitrogen to the gas-liquid separator to dilute the oxygen content. This measure can effectively guarantee the safety of the hydrogenation reaction system of the hydrogen peroxide plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com