Self-flushing water purifier

A self-flushing, water purifier technology, applied in mechanical equipment, engine components, multi-stage water treatment, etc., can solve the problems of affecting the working efficiency of the filter element, waste of replacing the filter element, troublesome folding and cleaning, etc., to improve work efficiency and use. Cycle, work efficiency and life cycle improvement, the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings.

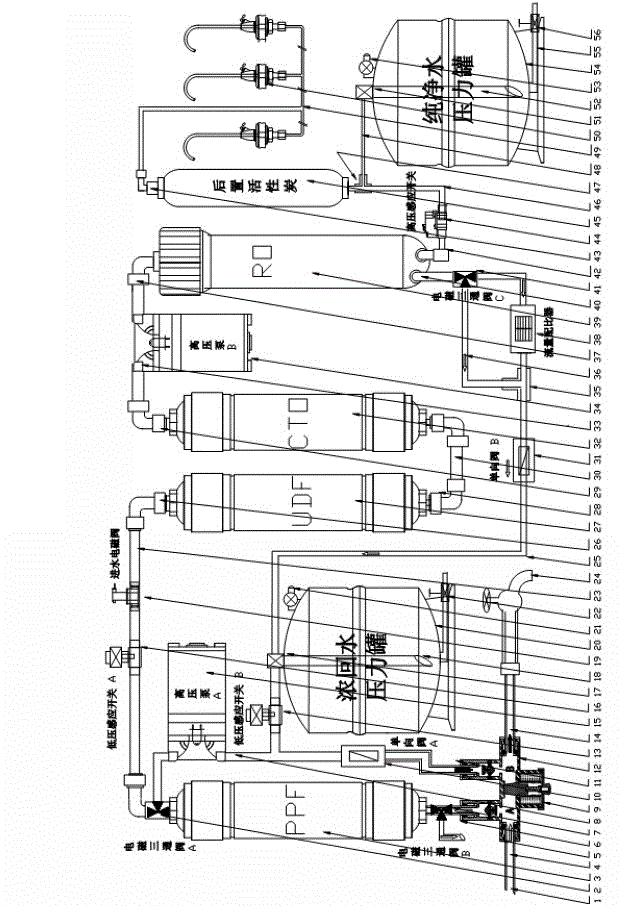

[0047] Such as figure 1 As shown, the flushing objects of the self-flushing water purifier are the PPF filter element (3) and the RO membrane filter element (39); the power for flushing the PPF filter element (3) and the RO membrane filter element (39) is respectively Provided by high pressure pump A (15) and high pressure pump B (34).

[0048] Such as figure 1 As shown, the flushing of the PPF filter element (3) is carried out by the high-pressure pump A (15) in the backflush mode; the water inlet port and the water outlet port of the PPF filter element (3) are respectively provided with electromagnetic valves of the same specification and model. Reversing valve B (7) and electromagnetic reversing valve A (2).

[0049] Such as figure 1 As shown, the upper port of the electromagnetic reversing valve B (7) is connected to the water inlet port of the PPF filter ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap