Regeneration of metal nitric acid and hydrofluoric acid pickling waste liquid and recovery process of metal elements

A hydrofluoric acid and metal technology, applied in the fields of mechanical processing, steel and metal, can solve the problems of high operating cost, large investment, and high recovery rate of metal elements, and achieve low operating costs, many recycled resources, and low investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

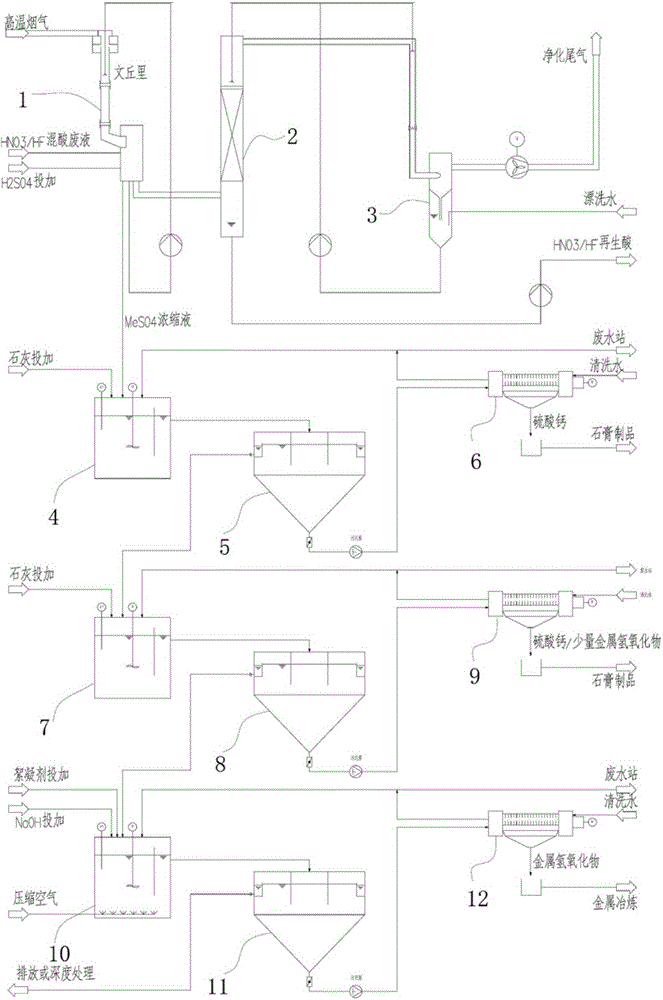

[0031] figure 1 The structure of the metal nitric acid, hydrofluoric acid pickling waste regeneration and metal element recovery system provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0032] refer to figure 1 , the present embodiment provides a kind of regeneration of metal nitric acid, hydrofluoric acid pickling waste liquor and the recycling process of metal elements, comprising the following steps:

[0033] S101. Put metal pickling waste liquid into sulfuric acid to make it undergo a displacement reaction with sulfuric acid, and send the obtained mixed waste liquid into Venturi heat exchanger 1, and exchange heat with high-temperature gas by spraying, and separate HNO 3 and HF gas, and discharge the concentrated waste liquid from the bottom of the Venturi heat exchanger 1 sump.

[0034] In this step, the metal pickling waste liquid includes at l...

Embodiment 2

[0061] The metal nitric acid provided by the present embodiment, the regeneration of hydrofluoric acid pickling waste liquor and the recycling process of metal elements comprise the following steps:

[0062] S201. Put metal pickling waste liquid into sulfuric acid to make it undergo a displacement reaction with sulfuric acid, and send the obtained mixed waste liquid into Venturi heat exchanger 1 to exchange heat with high-temperature gas by spraying, and separate HNO 3 and HF gas, and discharge the concentrated waste liquid from the bottom of the Venturi heat exchanger 1 sump;

[0063] S202, the concentrated waste liquid is discharged into the No. 1 reaction tank 4, calcium hydroxide or calcium oxide is added and stirred, and the calcium sulfate and water mixture generated by the reaction are discharged into the No. 1 sedimentation tank 5, after the calcium sulfate is precipitated, The precipitated sludge is lifted by the pump and enters No. 1 filter press 6 for dehydration b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com