Treatment process of high ammonia-nitrogen organic wastewater

A technology of organic wastewater and treatment process, applied in multi-stage water treatment, degassed water/sewage treatment, neutralized water/sewage treatment, etc. Achieve the effect of improving purity, overcoming resistance loss and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

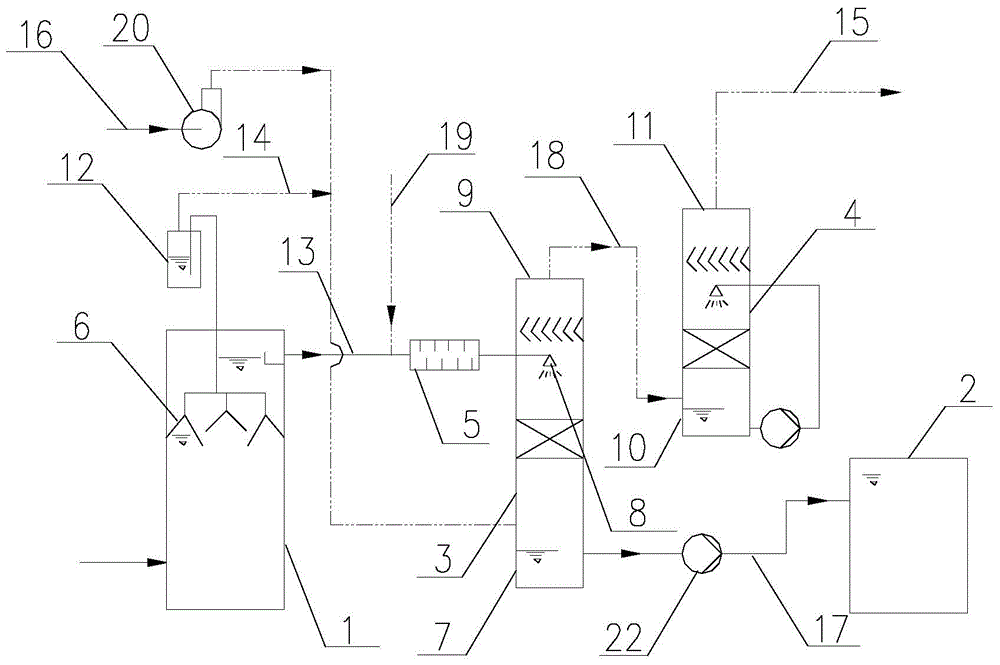

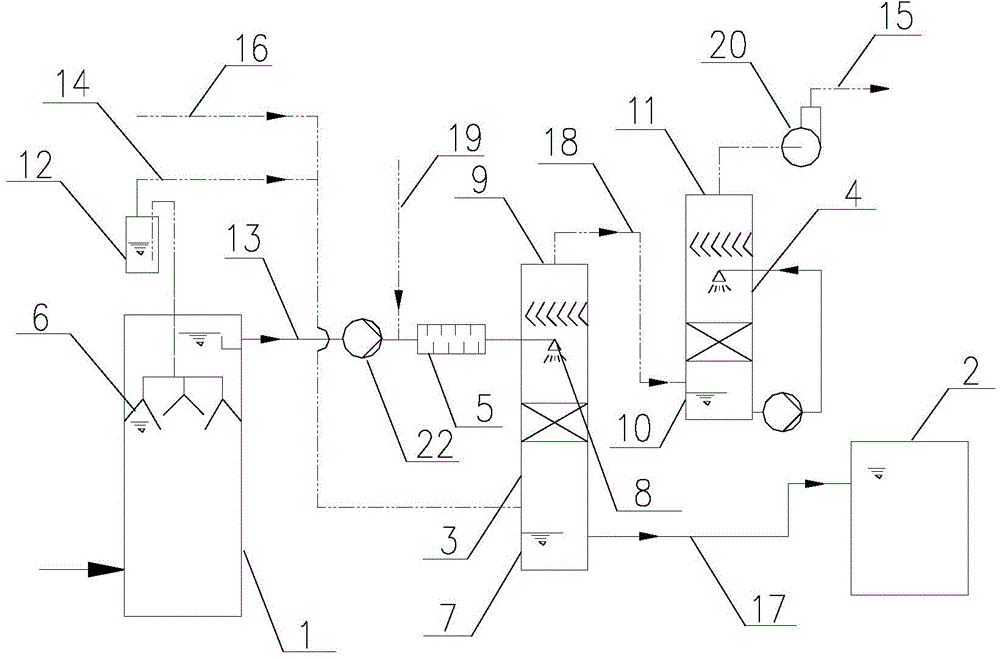

[0028] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] A treatment process for high ammonia nitrogen organic wastewater, including an anaerobic section, a stripping section, an absorption device, an aerobic section, and a biogas treatment section,

[0030] (1) Wastewater containing high ammonia nitrogen concentration is treated in the anaerobic section, then enters the blowing section through the anaerobic outlet pipeline for treatment, and before the anaerobic outlet pipeline enters the blowoff section, lye is added through the lye pipeline to adjust the pH value;

[0031] (2) The ammonia nitrogen stripping section uses the biogas generated in the anaer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com