A kind of powder for preparing magnesium-silicon hard insulation board, magnesium-silicon hard insulation board and preparation method thereof

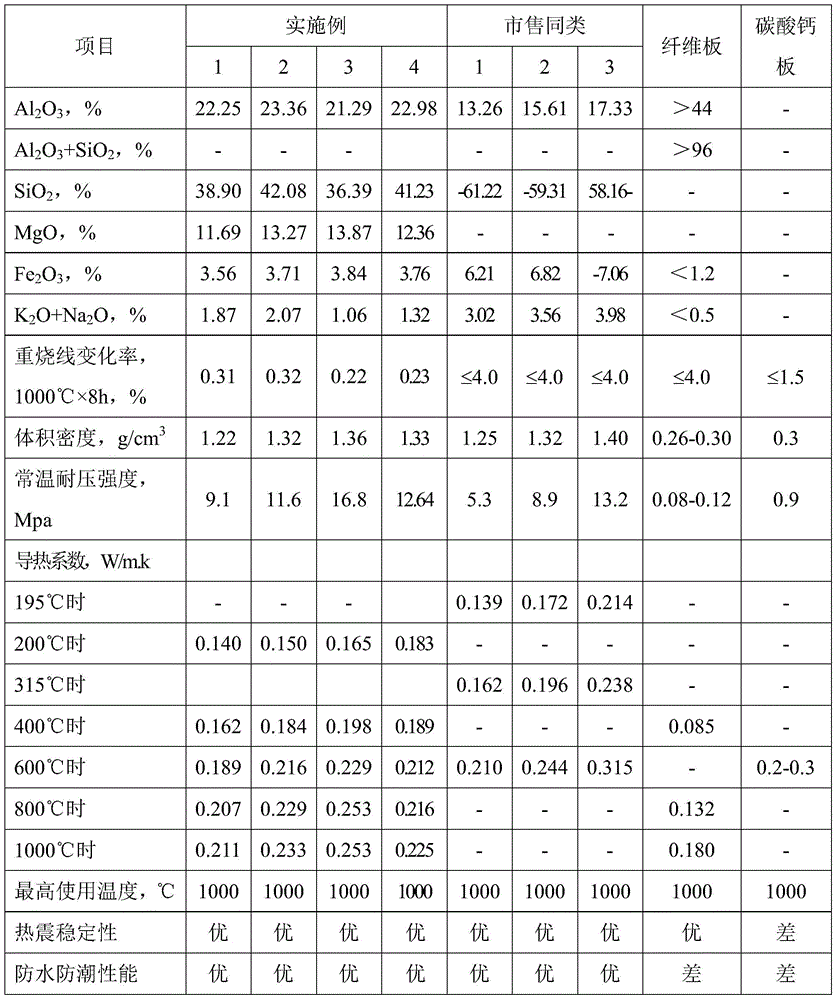

A thermal insulation board and hard technology, applied in the field of thermal insulation materials, can solve the problems of poor thermal insulation performance, low structural strength, poor thermal shock stability, etc., and achieve good waterproof and moisture-proof performance, good heat insulation performance, and low high-temperature shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The powder used to prepare the magnesium-silicon hard insulation board in this embodiment includes the following components in parts by weight: 40 parts of vermiculite powder, 12 parts of floating beads, 15 parts of clay powder, 10 parts of alumina powder, and 3 parts of silicon micropowder. 10 parts, expanded perlite 10 parts, aluminate cement 10 parts.

[0034] The specification of the vermiculite powder is 0.1-1.5mm; the specification of the floating beads is 20-40 mesh; the specification of the clay powder is ≥250 mesh; the specification of the alumina powder is ≥320 mesh; The specification is ≥1000 mesh; the specification of the expanded perlite is 0.1-1.0mm; the specification of the aluminate cement is CA80.

[0035] The magnesium-silicon hard insulation board of this embodiment is mainly made of the following raw materials in parts by weight: 40 parts of vermiculite powder, 12 parts of floating beads, 15 parts of clay powder, 10 parts of alumina powder, 3 parts o...

Embodiment 2

[0041] The powder used to prepare the magnesium-silicon hard insulation board in this embodiment includes the following components in parts by weight: 37 parts of vermiculite powder, 18 parts of floating beads, 12 parts of clay powder, 8 parts of alumina powder, and 4 parts of silicon micropowder. parts, expanded perlite 13 parts, aluminate cement 8 parts.

[0042] The specification of the vermiculite powder is 0.1-1.5mm; the specification of the floating beads is 20-40 mesh; the specification of the clay powder is ≥250 mesh; the specification of the alumina powder is ≥320 mesh; The specification is ≥1000 mesh; the specification of the expanded perlite is 0.1-1.0mm; the specification of the aluminate cement is CA80.

[0043] The magnesium-silicon hard insulation board of this embodiment is mainly made of the following raw materials in parts by weight: 37 parts of vermiculite powder, 18 parts of floating pearls, 12 parts of clay powder, 8 parts of alumina powder, 4 parts of sil...

Embodiment 3

[0049] The powder used to prepare the magnesium-silicon hard insulation board in this embodiment includes the following components in parts by weight: 42 parts of vermiculite powder, 20 parts of floating beads, 10 parts of clay powder, 5 parts of alumina powder, and 5 parts of silicon micropowder. 10 parts, expanded perlite 10 parts, aluminate cement 8 parts.

[0050] The specification of the vermiculite powder is 0.1-1.5mm; the specification of the floating beads is 20-40 mesh; the specification of the clay powder is ≥250 mesh; the specification of the alumina powder is ≥320 mesh; The specification is ≥1000 mesh; the specification of the expanded perlite is 0.1-1.0mm; the specification of the aluminate cement is CA80.

[0051] The magnesium-silicon hard insulation board of this embodiment is mainly made of the following raw materials in parts by weight: 42 parts of vermiculite powder, 20 parts of floating beads, 10 parts of clay powder, 5 parts of alumina powder, 5 parts of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com