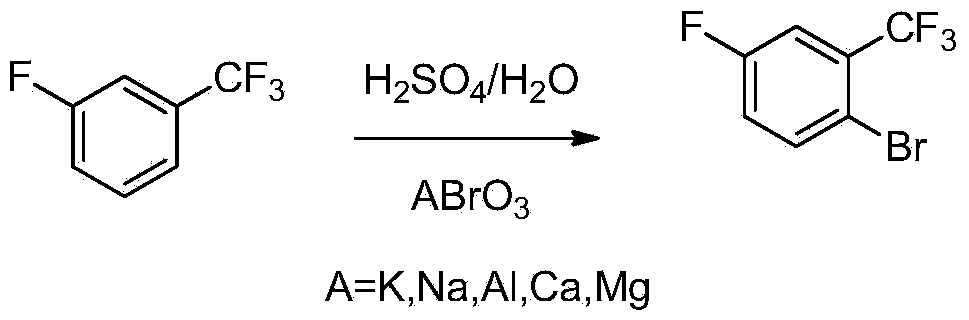

Method for preparing 2-bromine-5-fluorobenzotrifluoride

A technology of fluorobenzotrifluoride and m-fluorobenzotrifluoride, which is applied in the field of organic synthesis, can solve the problems of difficult availability of bromination reagents, high processing costs, and many synthesis steps, and achieve fewer reaction steps, simple and convenient operation, and high reaction efficiency. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 6.00kg of 70% sulfuric acid into a 10L glass reactor, pass through frozen brine, control the temperature below 30°C, add 0.66kg of m-fluorobenzotrifluoride under stirring, heat the mixture to keep the temperature at 45-50°C, divide Add 0.80kg powdered potassium bromate in 10 batches for about 4 hours. After the addition, continue to keep warm and stir for 2 hours. Take samples for analysis until the reaction is complete, quench, extract with 3L dichloromethane, wash with sodium sulfite, remove the solvent after alkali washing, and rectify The 158-162°C / 760mmHg fraction was collected to obtain a product with a weight of 0.92kg, a purity of 99.2%, and a yield of 93.9%.

Embodiment 2

[0025] Add 6.00kg of 70% sulfuric acid into a 10L glass reactor, pass through frozen brine, control the temperature below 30°C, add 0.66kg of m-fluorobenzotrifluoride under stirring, heat the mixture to keep the temperature at 45-50°C, divide Add 1.00kg powdered potassium bromate in 10 batches for about 4 hours. After the addition, continue to keep warm and stir for 2 hours. Take samples for analysis until the reaction is complete, quench, extract with 3L dichloromethane, wash with sodium sulfite, remove the solvent after alkali washing, and rectify The 158-162°C / 760mmHg fraction was collected to obtain a product with a weight of 0.91kg, a purity of 99.0%, and a yield of 92.7%.

Embodiment 3

[0027] Add 6.00kg of 70% sulfuric acid into a 10L glass reactor, pass through frozen brine (water bath, the same below), control the temperature below 30°C, add 0.66kg of m-fluorobenzotrifluoride under stirring, and heat the mixture to keep the temperature at 30~35℃, add 0.80kg powdered potassium bromate in 10 batches, about 4 hours, continue to keep warm and stir for 2 hours after adding, take samples and analyze until the reaction is completed, quench, extract with 3L dichloromethane, wash with sodium sulfite, wash with alkali After precipitating, rectification collects 158~162 ℃ / 760mmHg distillate, obtains product weight 0.90kg, purity 99.1%, yield 91.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com