Bra component material and manufacturing method thereof as well as bra component manufacturing method

A technology for underwear components and a manufacturing method, applied in the field of manufacturing materials, can solve the problems of inability to meet the development needs of modern underwear, lack of infrared radiation, sterilization, and restricting the high comfort of underwear, so as to promote breast development and shaping, and smooth blood flow. , the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Making underwear cups with natural energy benefits involves the following steps:

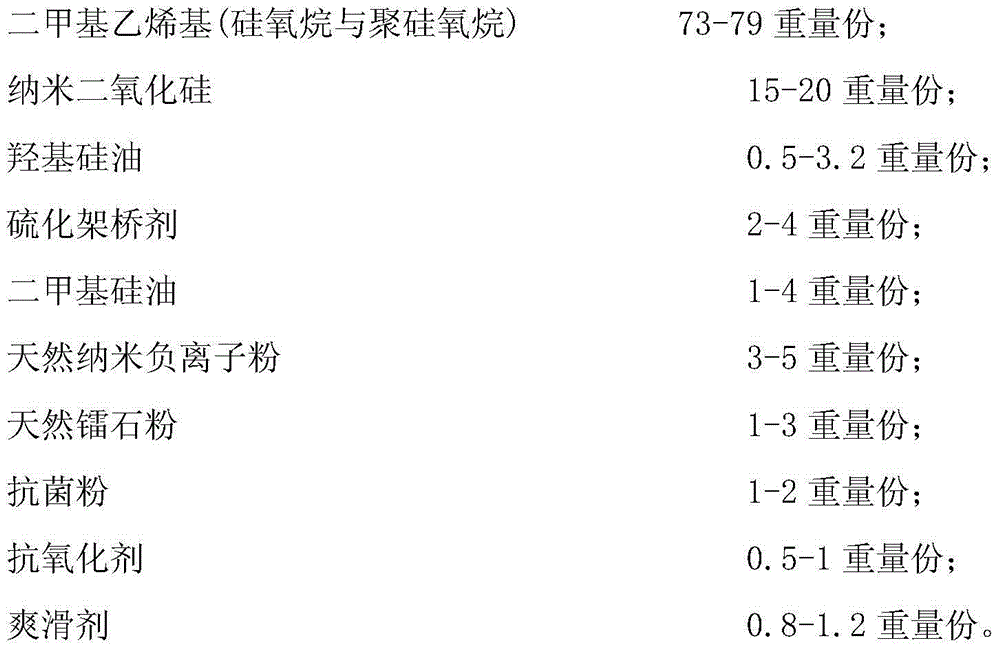

[0078] Step 1: Dissolve 73 parts by weight of semi-solid dimethylvinyl (siloxane and polysiloxane) into a kneader and preheat for 5 minutes with stirring, wherein the hydroxyl-terminated dimethylvinyl (silicon Oxane and polysiloxane) account for 2.1%, and the temperature is controlled between 150-220 degrees Celsius;

[0079] Step 2: Add 15 parts by weight of nano-silica to the above-mentioned open mill for stirring and re-training for about 10 minutes, so that the two materials of dimethyl vinyl (siloxane and polysiloxane) and nano-silica are mixed Uniform, filling effect;

[0080] Step 3: Add 0.5 parts by weight of hydroxy silicone oil and 1 part by weight of dimethyl silicone oil, and knead for about 5 minutes to make the viscosity uniform. At the same time, add 1 part by weight of natural nano-anion powder and stir well;

[0081]Step 4: Add 2 parts by weight of vulcanized bridging a...

Embodiment 2

[0092] Making underwear straps with natural energy benefits includes the following steps:

[0093] Step 1: Dissolve 79 parts by weight of semi-solid dimethylvinyl (siloxane and polysiloxane) into a kneader and preheat for 5 minutes with stirring, wherein the hydroxyl-terminated dimethylvinyl (silicon Oxane and polysiloxane) account for 2.6%, and the temperature is controlled between 150-220 degrees Celsius;

[0094] Step 2: Add 20 parts by weight of nano-silica to the above-mentioned open mill for stirring and re-training for about 10 minutes, so that the two materials of dimethyl vinyl (siloxane and polysiloxane) and nano-silica are mixed Uniform, filling effect;

[0095] Step 3: Add 3.2 parts by weight of hydroxy silicone oil and 4 parts by weight of dimethyl silicone oil, and knead for about 5 minutes to make the viscosity uniform. At the same time, add 2 parts by weight of natural nano-anion powder and stir well;

[0096] Step 4: Add 4 parts by weight of vulcanized bridg...

Embodiment 3

[0107] Making an underwear shaper belt with natural energy benefits includes the following steps:

[0108] Step 1: Dissolve 75 parts by weight of semi-solid dimethylvinyl (siloxane and polysiloxane) into the kneader and preheat for 5 minutes with stirring, wherein the hydroxyl-terminated dimethylvinyl (silicone Oxane and polysiloxane) account for 2.3%, and the temperature is controlled between 150-220 degrees Celsius;

[0109] Step 2: Add 18 parts by weight of nano-silica to the above-mentioned open mill for stirring and re-training for about 10 minutes, so that the two materials of dimethyl vinyl (siloxane and polysiloxane) and nano-silica are mixed Uniform, filling effect;

[0110] Step 3: Add 2.2 parts by weight of hydroxy silicone oil and 2 parts by weight of dimethyl silicone oil, and knead for about 5 minutes to make the viscosity uniform. At the same time, add 1.5 parts by weight of natural nano-anion powder and stir well;

[0111] Step 4: Add 3 parts by weight of vul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com