Multi-stage aging treatment method for aluminium-zinc-magnesium-copper 7000 series alloy thick plates

A technology of graded aging and treatment method, applied in the field of graded aging treatment of zinc, copper 7000 series alloy thick plate, aluminum, magnesium, can solve the problems of low fracture toughness, cracking sensitivity, etc., to improve fracture toughness, reduce sensitivity, improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

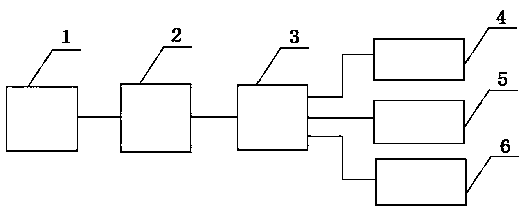

[0013] Embodiment, with reference to accompanying drawing, a kind of aluminum, zinc, magnesium, copper 7000 series alloy thick plate graded aging treatment method, it is characterized in that taking the following steps:

[0014] a. Put aluminum, zinc, magnesium, copper 7000 series alloy thick plates in box type quenching furnace 1 for quenching treatment, the quenching temperature is raised to 477±3°C, and the holding time is 80~100min; quenching transfer time t1≤30~ 50s;

[0015] b. the aluminum, zinc, magnesium, copper 7000 series alloy thick plate after quenching treatment is cooled in the water cooling container 2;

[0016] c. Put the cooled aluminum, zinc, magnesium, and copper 7000 series alloy thick plates in the aging furnace 3 for three-stage aging treatment. The first-stage aging temperature is 120±3°C, and the holding time is 4~6h; the second-stage The aging temperature is 155±3℃, and the holding time is 24~28h; the third aging temperature is 120±3℃, and the holdin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com