Non-bearing building block and special production equipment thereof

A production equipment, non-load-bearing technology, applied in the field of special production equipment, to achieve the effect of saving labor, good automation efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

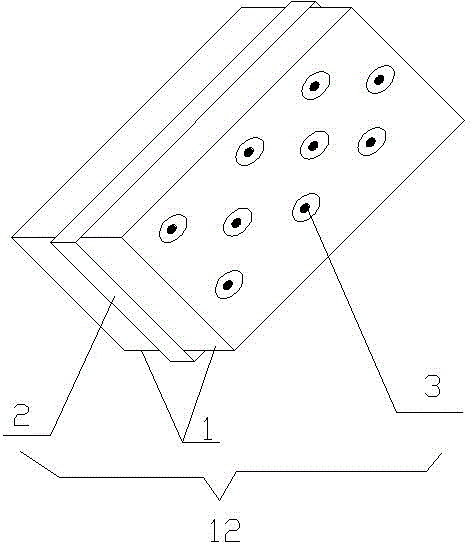

[0044] as attached figure 1 As shown, a non-load-bearing building block, the building block 12 is a three-layer structure, the upper and lower layers are respectively independent bricks 1, the middle layer is a heat preservation board 2, the bricks and the heat preservation board are rectangular, two bricks Between the block and the insulation board, the drill rods 3 are bound and connected by several non-heat-conducting materials.

[0045] as attached figure 1 As shown, one long side and two wide sides of the insulation board 2 exceed the edges of the bricks 1 on both sides by 0.5-1.5 cm respectively, and the other long side of the insulation board is aligned with the edges of the bricks on both sides.

[0046] In this embodiment, one long side of the insulation board 2 exceeds the edges of the bricks 1 on both sides by 1.5 cm, and the two wide sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com