Disassembling and assembling method for shield tunneling machine in tunnel

A disassembly method and technology of shield machine, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of large construction volume, poor conditions, complex construction conditions of shield machine, etc., to save construction time, reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

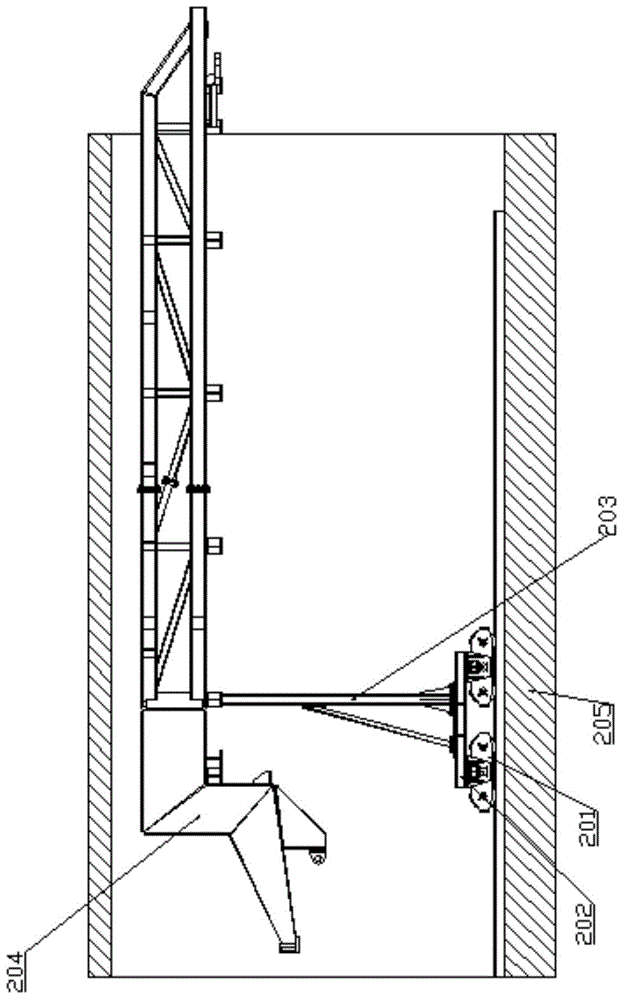

[0029] A method of disassembling and assembling a shield machine in a tunnel, please refer to Figure 1-5 , including the following steps:

[0030] ①Preparation before disassembly and entry

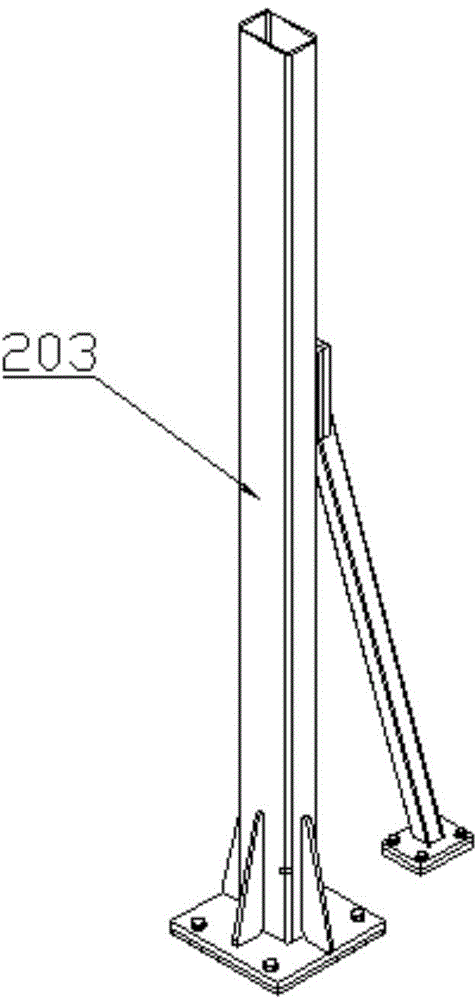

[0031] Firstly, a support mechanism 203 is provided, the length of which is at least greater than the height between the bridge of the shield machine and the ground.

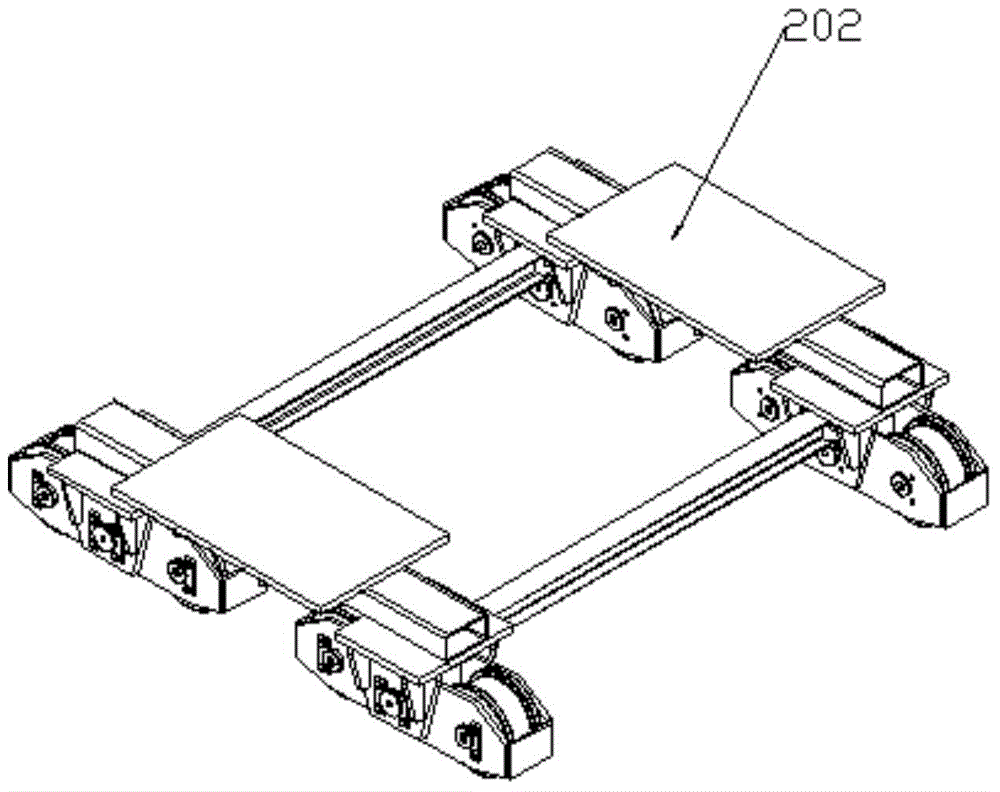

[0032] Secondly, remove the slice feeder in the tunnel, and lay the tunnel segment 201 to the slice machine with the rails 205 of the electric vehicle for transporting the segment, and park the segment transport battery car in the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com