Plasma phase-changing control air inlet passage and control method

A technology of plasma and air inlet, which is applied in the field of air inlet, can solve the problems affecting engine performance, engine surge, parking, etc., and achieve the effects of reducing separation, increasing engine thrust, and sufficient fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

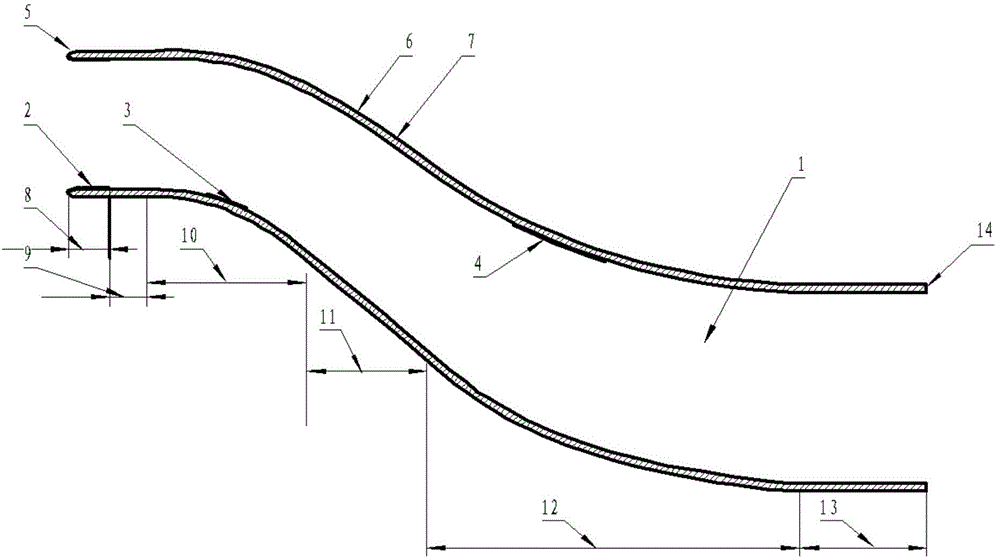

[0017] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

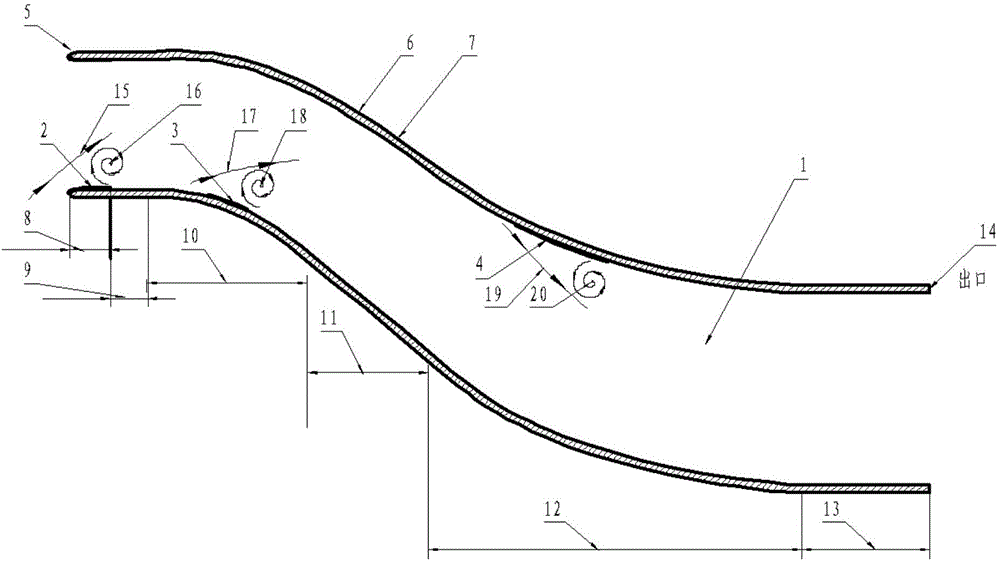

[0018] Phase-change flow control inlets based on bipolar plasma actuators, such as figure 2 As shown, the air intake form is: rectangular air inlet 100mm*84mm, circular outlet diameter 128mm, consisting of lip 8, throat 9, first bend 10, middle bend 11, second bend 12 and rear Straight segment 13 is composed. The first bipolar plasma actuator 2 is arranged at the lip 8, the second bipolar plasma actuator 3 is arranged in the airflow separation area of the first bend, and the third bipolar plasma actuator 4 is arranged in the first bend 2 Bend airflow separation area.

[0019] When the airflow separates at the lip 8, the lip separation airflow 15 airflow moves away from the surface of the lip 8 and forms a lip vortex 16 in reverse motion, the same situation will occur at the first bend 10 and the second bend Road 12 appears, the 1st bend separation airflow 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com