Sealing assembly for universal joint for crossed shaft type universal shaft coupler

A technology for universal couplings and sealing components, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., and can solve problems such as increased friction, increased sealing temperature, and vicious cycle at the lip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

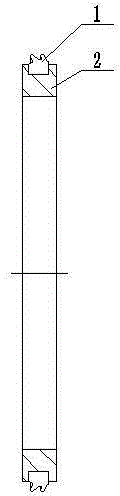

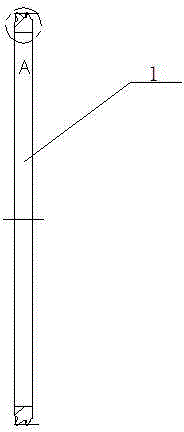

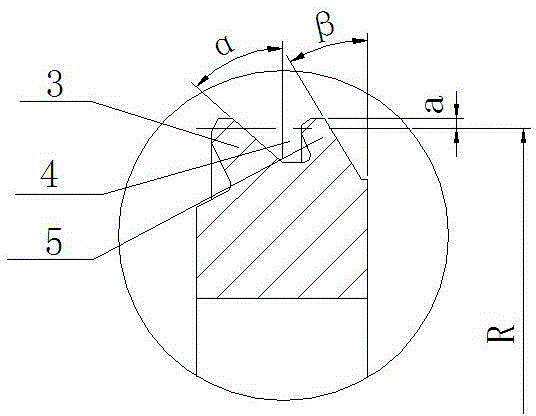

[0019] Such as figure 1 , 2 , 3, the sealing assembly for the universal joint of the cross-shaft universal joint, which includes a seal 1 and a seal seat 2, the outer side of the seal is provided with a main seal lip 3 and a secondary seal lip inclined relative to the seal Port 5, the two sealing lips are inclined toward the left end face of the seal, the auxiliary sealing lip is located at the edge of the seal, the main sealing lip is at an angle of 40°-50° to the axial direction of the seal, and the auxiliary sealing lip It is at an angle of 25°~30° to the axial direction of the seal, and a U-shaped cavity 4 is formed between the main sealing lip and the auxiliary sealing lip. The thickness of the main sealing lip is 0.8-1.5mm, and the thickness of the auxiliary sealing lip is 80% of the thickness of the main sealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com