A crawler-type meter counting device

A meter-counting device and crawler-type technology, applied in the field of length measuring devices, can solve the problems of meter-counting error, wheel-type meter-counter large meter-counting error, large difference in positive pressure, etc., so as to reduce the influence of meter-counting accuracy and stabilize Synchronization performance, the effect of improving meter accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

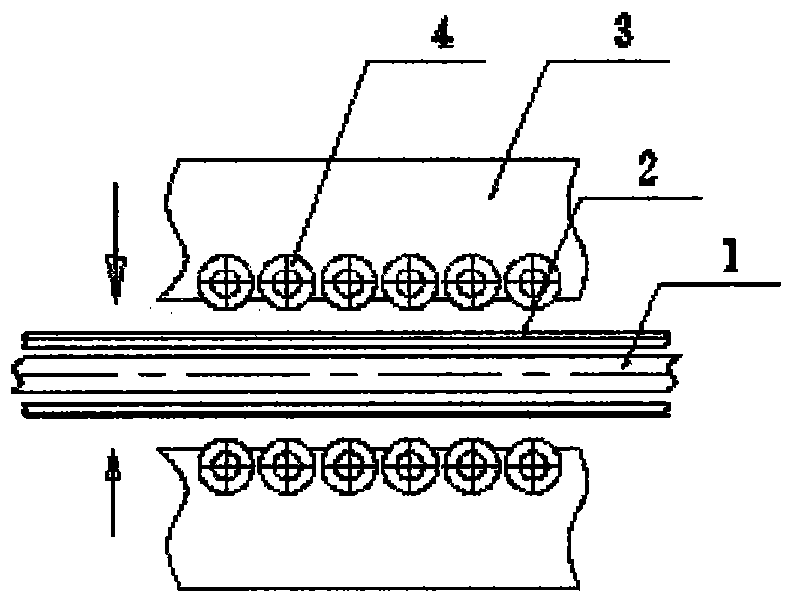

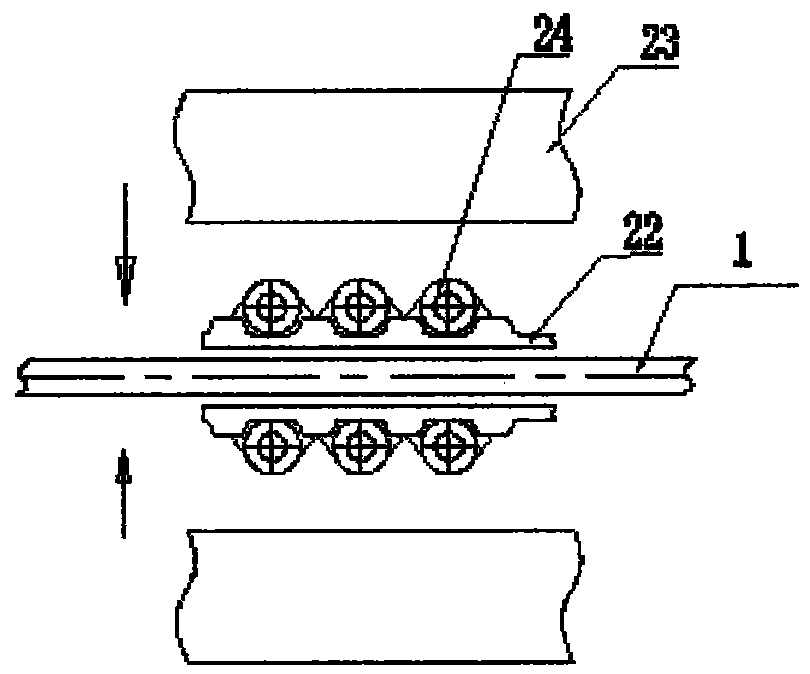

[0029] The crawler-type meter counting device of embodiment 2 is as image 3 and Figure 4 As shown, the difference from Embodiment 1 is that a different pressure applying mechanism is used. The pressure applying mechanism of this embodiment includes a pressure block 26 and an intermediate pressure transmission block 23 arranged on the inner side of the corresponding clamping contact section and can move up and down. , the middle pressure transmission block is located between the pressure block 26 and the clamping contact section of the synchronous belt, and the inner belt surface of the synchronous belt 22 extends along the belt length direction and is provided with an annular track 27, the track surface of which is a plane structure, and the middle pressure transmission The block 23 is rotated at intervals along the length direction of the clamping contact section to be equipped with a force transmission rolling body 24. The force transmission rolling body adopts a roller mo...

Embodiment 1

[0030]In Embodiment 1 and Embodiment 2, the force-transmitting rolling body adopts rollers, and in other embodiments, the force-transmitting rolling body can also be replaced by rollers.

Embodiment 3

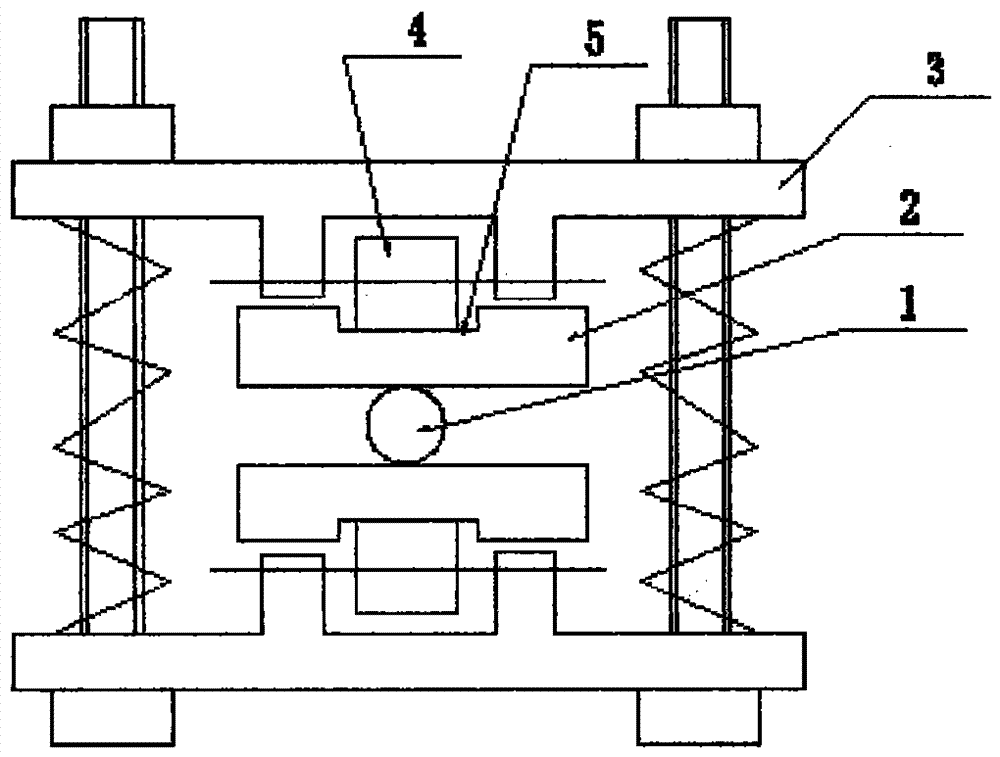

[0031] The crawler type meter counting device of embodiment 3 is as Figure 5-Figure 9 As shown, it includes a base 41, a length-measuring synchronous belt assembly, a pressing assembly and a guide wheel assembly, wherein two left and right guide rods 42 are fixedly arranged on the base 41, and the two guide rods extend along the up and down direction, are parallel to each other, and are arranged at intervals .

[0032] The guide wheel assembly includes a guide wheel beam 43 extending left and right and a guide wheel 44 rotatably assembled at both ends of the beam. The guide wheel is used to guide and support the cable or wire 1 to be tested. The guide wheel is made of wear-resistant, strong and tough Made of high-molecular polyethylene material, the wheels are designed as grooved wheels, and processed by the unified datum plane of the machining center. The guide wheel beam 43 is assembled on the guide rod 42 through the linear bearings arranged at intervals on the left and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com