Array type annular electrostatic sensor and pneumatic transmission powder measurement device and method

An electrostatic sensor and array technology, which is used in measuring devices, electrostatic field measurement, conveying bulk materials, etc., can solve the problems of instrument failure, low reliability, measurement errors, etc., to achieve convenient installation and maintenance, wide measurable range, Implement simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

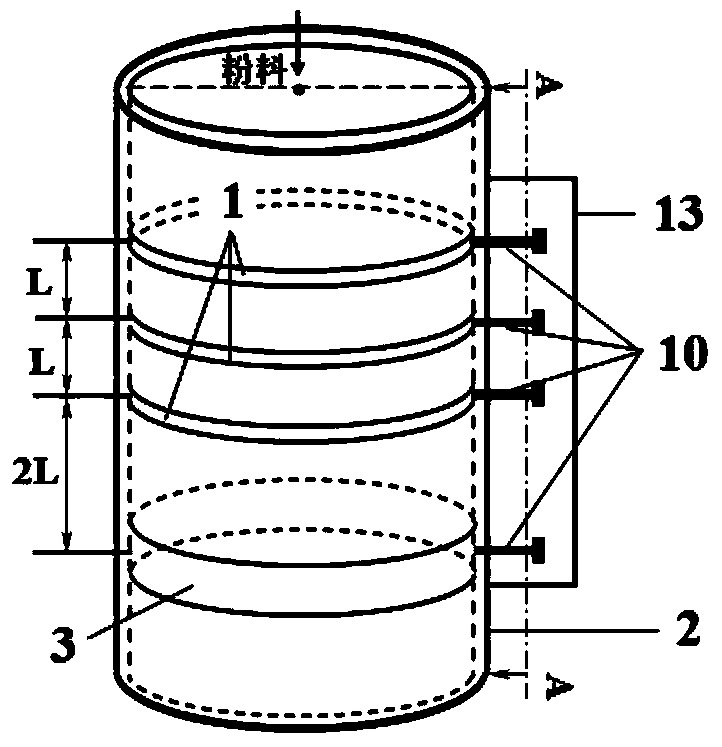

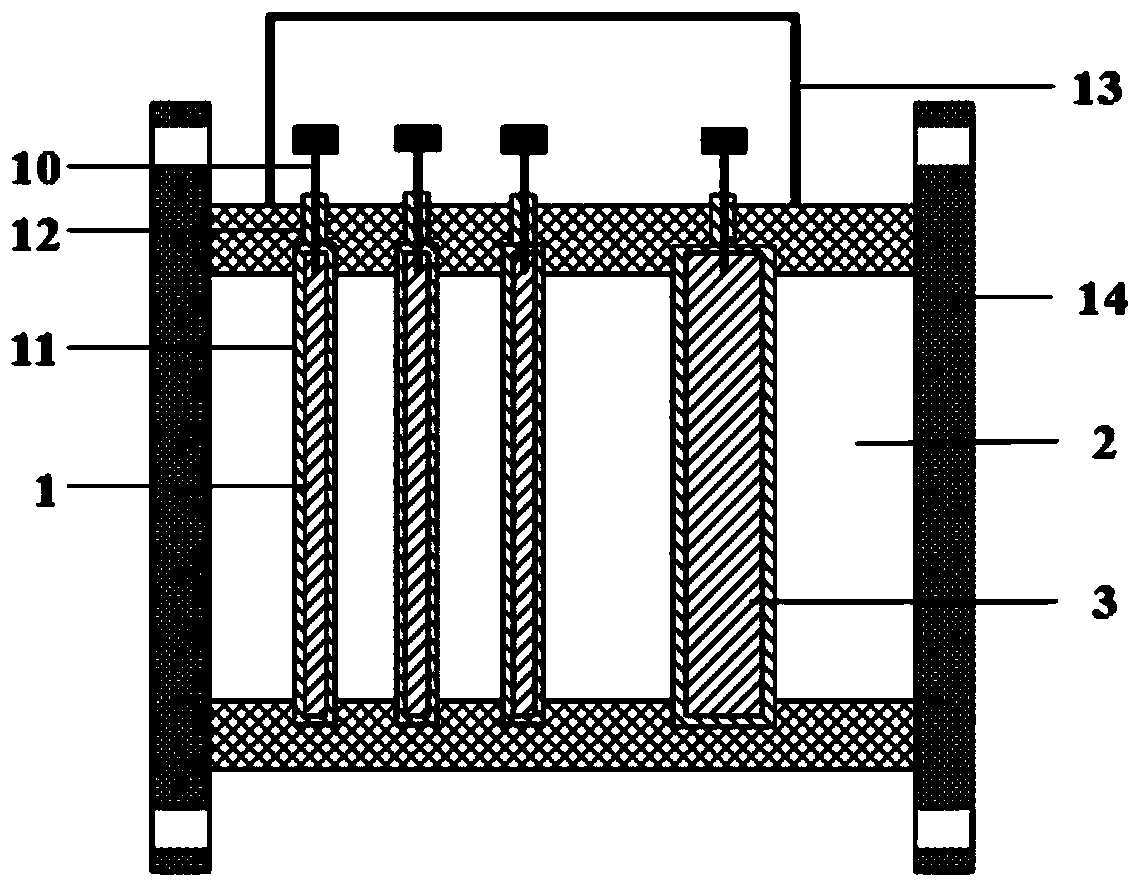

[0031] figure 2 Schematic diagram of the structure of the arrayed annular electrostatic sensor provided by the embodiment of the present invention; image 3 for figure 2 A-A sectional schematic of the sensor and mounting flange shown. Depend on figure 2 and image 3 It can be seen that:

[0032] The array type annular electrostatic sensor provided in this embodiment includes a metal tubular body 2, and at least one set of first metal electrodes 1 and at least one set of second metal electrodes are arranged side by side on the inner peripheral surface of the metal tubular body 2. 3. The first metal electrode 1 and the second metal electrode 3 are annular, and the axial width of the first metal electrode 1 is smaller than the axial width of the second metal electrode 3 . The second metal electrode is used for powder flow measurement, and the first metal electrode is used for powder flow velocity measurement and serves as an auxiliary flow measurement. The axial sensitiv...

Embodiment 2

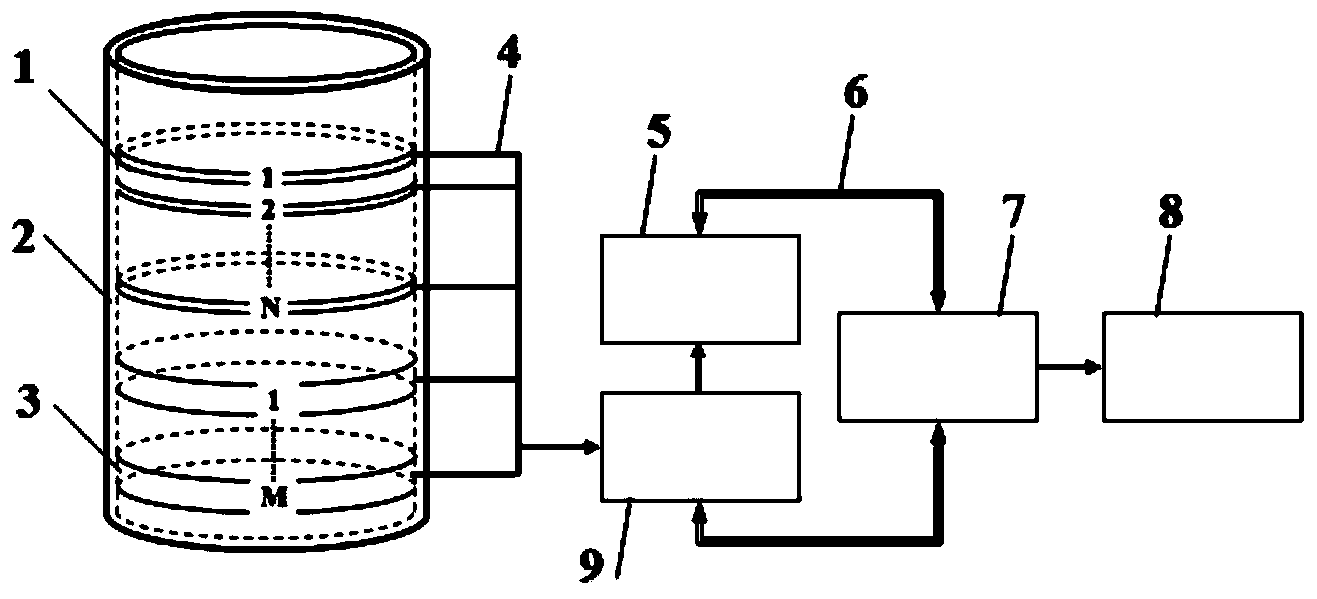

[0043] This embodiment provides a pneumatically conveyed powder measuring device based on an array type annular electrostatic sensor. figure 1 Schematic diagram of the structure of the pneumatic conveying powder measuring device provided by the embodiment of the present invention. Depend on figure 1 It can be seen that the pneumatically conveyed powder measuring device based on the arrayed annular electrostatic sensor involved in this embodiment includes an arrayed annular electrostatic sensor, an embedded signal processing module, a multi-data fusion module and a central analysis module:

[0044] A plurality of the aforementioned array-type annular electrostatic sensors are used to obtain electrostatic signals caused by powder flow;

[0045] The embedded signal processing module is used to receive and process the electrostatic signal obtained by the array ring electrostatic sensor to obtain the electrostatic digital signal, and obtain the flow velocity information and flow i...

Embodiment 3

[0051] This embodiment provides a method for measuring pneumatically conveyed powder based on an annular electrostatic sensor, which mainly includes the following steps:

[0052] Step 1. A plurality of the aforementioned arrayed annular electrostatic sensors are used to obtain electrostatic signals caused by powder flow;

[0053] Step 2, the embedded signal processing module receives the electrostatic signal obtained by the array ring electrostatic sensor to obtain the electrostatic digital signal, and obtains the flow velocity information and flow information of the powder according to the electrostatic digital signal; the processing is to The electrostatic signal undergoes current / voltage conversion (the electrostatic signal is converted into a voltage signal through resistance), amplification and filtering, and then performs analog / digital signal conversion; at the same time, the embedded microprocessor is used to process the powder flow velocity and flow information;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com