A kind of plastic edge banding strip with 3D effect and preparation process thereof

A technology of 3D effect and preparation process, which is applied in furniture accessories, furniture parts, household appliances, etc., can solve the problem of glue stitches at the bonding between the glue layer and the board surface, the amount of glue material is large, and the appearance of the finished product is unsightly. and other problems, to avoid degumming, better stereoscopic vision, and better product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of the plastic edge banding strip with 3D effect of this embodiment comprises the following preparation steps:

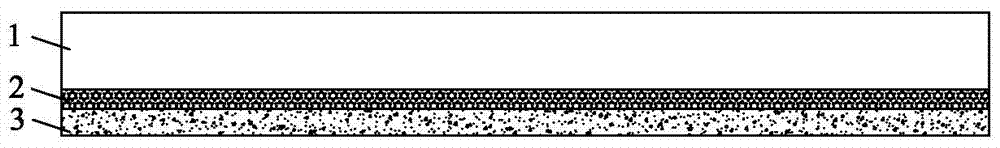

[0032] a. Extrude the transparent plastic raw material to make a transparent edge banding base sheet, and then cut the transparent edge banding base sheet to obtain a strip-shaped transparent base layer 1. The thickness of the transparent base layer 1 is 0.4 mm;

[0033] b. Use ink to print the pattern layer 2 on the lower surface of the strip-shaped transparent base layer 1 to obtain the primary product of the plastic edge banding strip;

[0034] c. Start the heating device of the gluing unit of the gluing machine, heat the gluing unit at 140°C for 15 minutes, then put the finished plastic edging into the gluing unit of the gluing machine for scraping and heating Melt glue, scrape the ethylene-vinyl acetate copolymer hot melt adhesive on the lower surface of the pattern layer 2 from the slit nozzle of the edge banding gluer, the temp...

Embodiment 2

[0037] The preparation process of the plastic edge banding strip with 3D effect of this embodiment comprises the following preparation steps:

[0038] a. Extrude the transparent plastic raw material to make a transparent edge banding base sheet, and then cut the transparent edge banding base sheet to obtain a strip-shaped transparent base layer 1. The thickness of the transparent base layer 1 is 0.6 mm, the surface at the corner of the transparent substrate layer 1 is curved;

[0039] b. Use ink to print the pattern layer 2 on the lower surface of the strip-shaped transparent base layer 1 to obtain the primary product of the plastic edge banding strip;

[0040] c. Start the heating device of the gluing unit of the gluing machine, heat the gluing unit at 145°C for 18 minutes, then put the finished plastic edging into the gluing unit of the gluing machine for scraping and heating Melt glue, scrape thermoplastic rubber hot melt glue on the lower surface of the pattern layer 2 fr...

Embodiment 3

[0043] The preparation process of the plastic edge banding strip with 3D effect of this embodiment comprises the following preparation steps:

[0044] a. Extrude the transparent plastic raw material to make a transparent edge banding base sheet, then cut the transparent edge banding base sheet to obtain a strip-shaped transparent base layer 1, the thickness of which is 1mm , the surface at the corners of the transparent substrate layer 1 is wavy;

[0045] b. Use ink to print the pattern layer 2 on the lower surface of the strip-shaped transparent base layer 1 to obtain the primary product of the plastic edge banding strip;

[0046] c. Start the heating device of the gluing unit of the gluing machine, heat the gluing unit at 150°C for 20 minutes, then put the finished paper-plastic edging into the gluing unit of the gluing machine for scraping and heating Melt glue, scrape polyamide hot melt adhesive on the lower surface of the pattern layer 2 from the slit nozzle of the edge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com