Debris flow blocking structure capable of resisting impact of large stones for steel pipe concrete pile group

A technology for concrete-filled steel tube piles and reinforced concrete, which is applied in water conservancy projects, marine engineering, coastline protection, etc. The effect of improving compressive strength and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

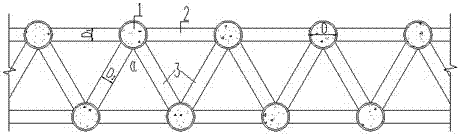

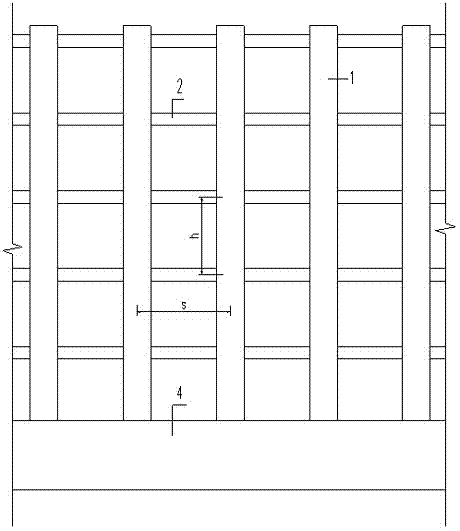

[0013] Example 1: When the apex angle ɑ of the isosceles triangle is 45°, the outer diameter D of the hollow steel pipe beam 2 1 Ratio to the outer diameter D of pile pipe 1: D 1 / D=0.43, the outer diameter D of the hollow steel pipe beam 3 2 Ratio to the outer diameter D of pile pipe 1: D 2 / D=0.33.

Embodiment 2

[0014] Embodiment 2: When the vertex angle α of the isosceles triangle is 60°, D 1 / D=0.43, the outer diameter D of the hollow steel pipe beam 3 2 Ratio to the outer diameter D of pile pipe 1: D 2 / D=0.43.

Embodiment 3

[0015] Example 3: When the apex angle ɑ of the isosceles triangle is 75°, the outer diameter D of the hollow steel pipe beam 2 1 Ratio to the outer diameter D of pile pipe 1: D 1 / D=0.38,D 2 / D=0.38. When the large stone particle size D m Known, s takes 1.5D m , s / h=1.5; s takes 1.75D m s / h=1.75; s is 2D m , s / h=2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com