Method for reducing smoke dust concentration measurement errors of thermal power plant flue gas

A technology for concentration measurement and thermal power plants, which is applied in measuring devices, material absorption weighing, suspension and porous material analysis, etc. It can solve problems such as weighing errors, easy loss of filter cartridges, strong water absorption of filter cartridges, etc., to achieve Reduce measurement errors, avoid weighing errors, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

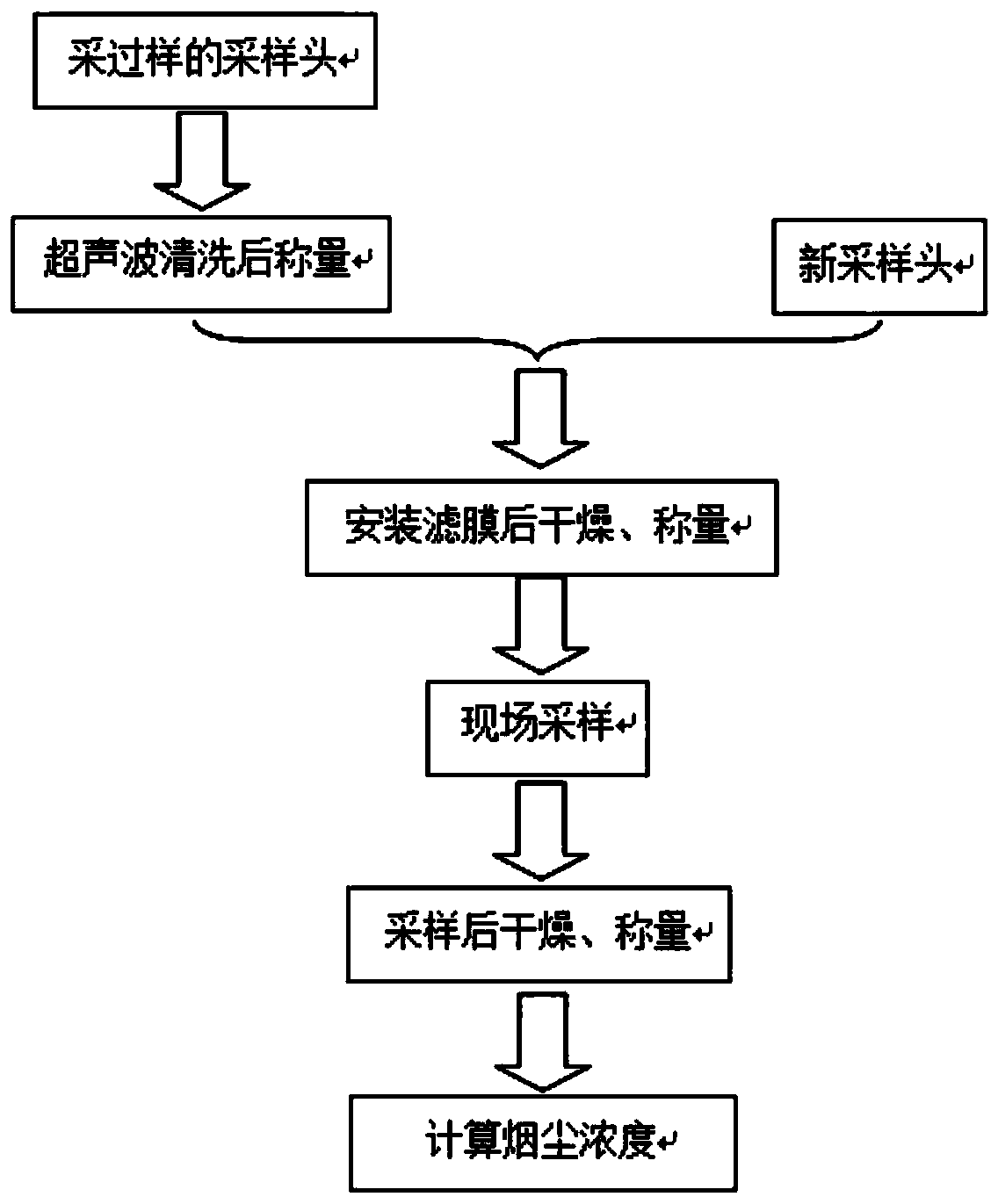

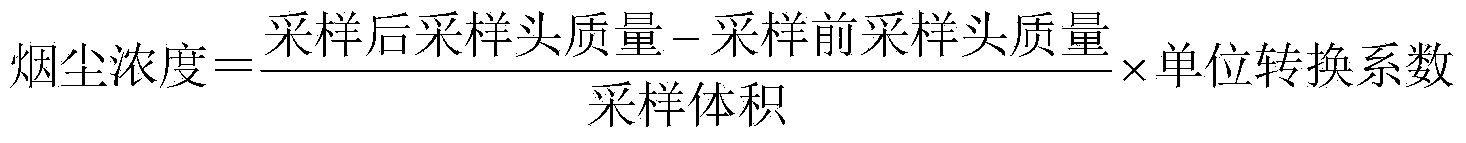

Method used

Image

Examples

Embodiment 1

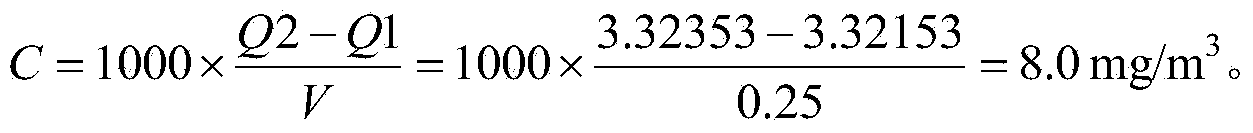

[0040] (1) Take a used sampling head (number 001), and clean the sampling head with ultrasonic waves for 40 minutes. After cleaning, dry it in a drying oven at 105°C for 2.5 hours, and then balance it on a one-hundred-thousandth balance Weigh it under, the result is 3.01236g; then use ultrasonic to clean the sampling head again for 40 minutes, after cleaning, dry it in a drying oven at 105°C for 2.5 hours, then weigh it under the balance of 1 / 100,000, the result is 3.01234g, the mass difference between the two times is 0.00002g (ie 0.02mg), less than 0.1mg;

[0041](2) Install a filter membrane (No. 001) on the sampling head, dry it in a drying oven at 105°C for 2.5 hours, then weigh it under a one-hundred-thousandth balance, and record the weighing mass as 3.32154g; then dry it again Dry it at 105°C for 2.5 hours, weigh it on a one-hundred-thousandth balance, and record the weighing mass as 3.32153g; the difference between the two weighings Δm is 0.01mg, which is less than 0....

Embodiment 2

[0048] (1) Take a used sampling head (No. 002), and clean the sampling head with ultrasonic wave for 30 minutes. After cleaning, dry it in a drying oven at 100°C for 2 hours, and then balance it in one hundred thousandth of the balance. Weigh it under the ground, and the result is 3.01224g; then clean the sampling head again with ultrasonic waves for 30 minutes, after cleaning, dry it in a drying oven at 100°C for 2 hours, and then weigh it under a one-hundred-thousandth balance, the result is 3.01222g, the mass difference between the two times is 0.00002g (ie 0.02mg), less than 0.1mg;

[0049] (2) Install a filter membrane (No. 002) on the sampling head, dry it in a drying oven at 100°C for 2 hours, then weigh it under a one-hundred-thousandth balance, and record the weighing mass as 3.32142g; then dry it again Dry it at 100°C for 2 hours, weigh it on a one-hundred-thousandth balance, and record the weighing mass as 3.32141g; the difference between the two weighings Δm is 0.0...

Embodiment 3

[0056] (1) Take a used sampling head (number 003), and clean the sampling head with ultrasonic waves for 60 minutes. After cleaning, dry it in a drying oven at 105°C for 4 hours, and then balance it on a one-hundred-thousandth balance Weigh it under, and the result is 3.01248g; then clean the sampling head again with ultrasonic waves for 60 minutes, after cleaning, dry it in a drying oven at 105°C for 4 hours, and then weigh it under a one-hundred-thousandth balance, the result is 3.01246g, the mass difference between the two times is 0.00002g (ie 0.02mg), less than 0.1mg;

[0057] (2) Install a filter membrane (No. 003) on the sampling head, dry it in a drying oven at 105°C for 4 hours, then weigh it under a one-hundred-thousandth balance, and record the weighing mass as 3.32166g; then dry it again Dry in the oven at 105°C for 4 hours, weigh it on a one-hundred-thousandth balance, and record the weighing mass as 3.32165g; the difference between the two weighings Δm is 0.01mg,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com