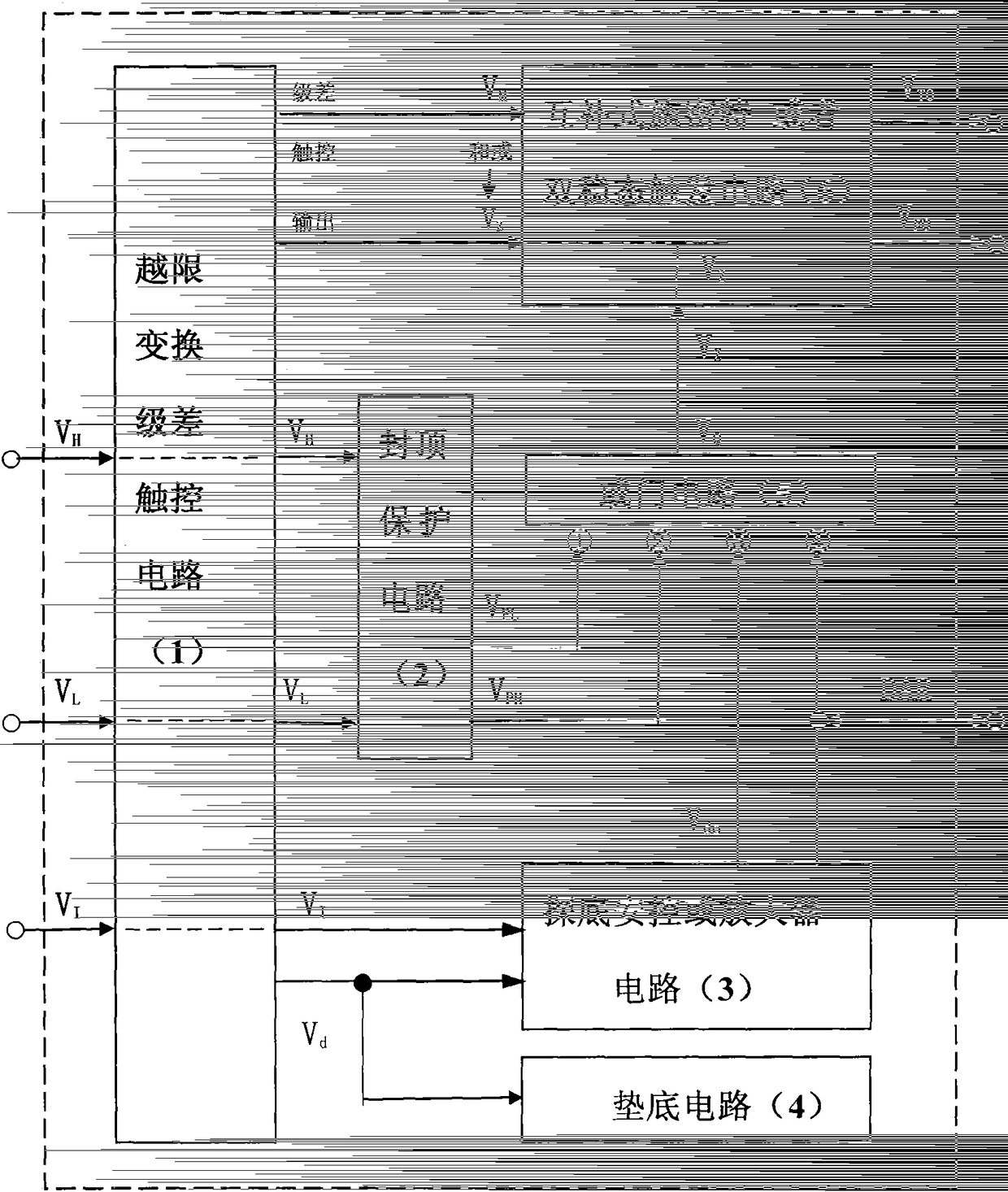

Top-sealing and bottom safety control circuit and its safety temperature and time control electrical appliances

A technology of touch circuit and circuit, which is applied in the direction of program control, instrument and program control in the sequence/logic controller, which can solve the problems of the input terminal exceeding the bottom limit, out of control, and mutual short circuit failure of the ports, so as to avoid serious out of control Accidents, improved safety performance, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

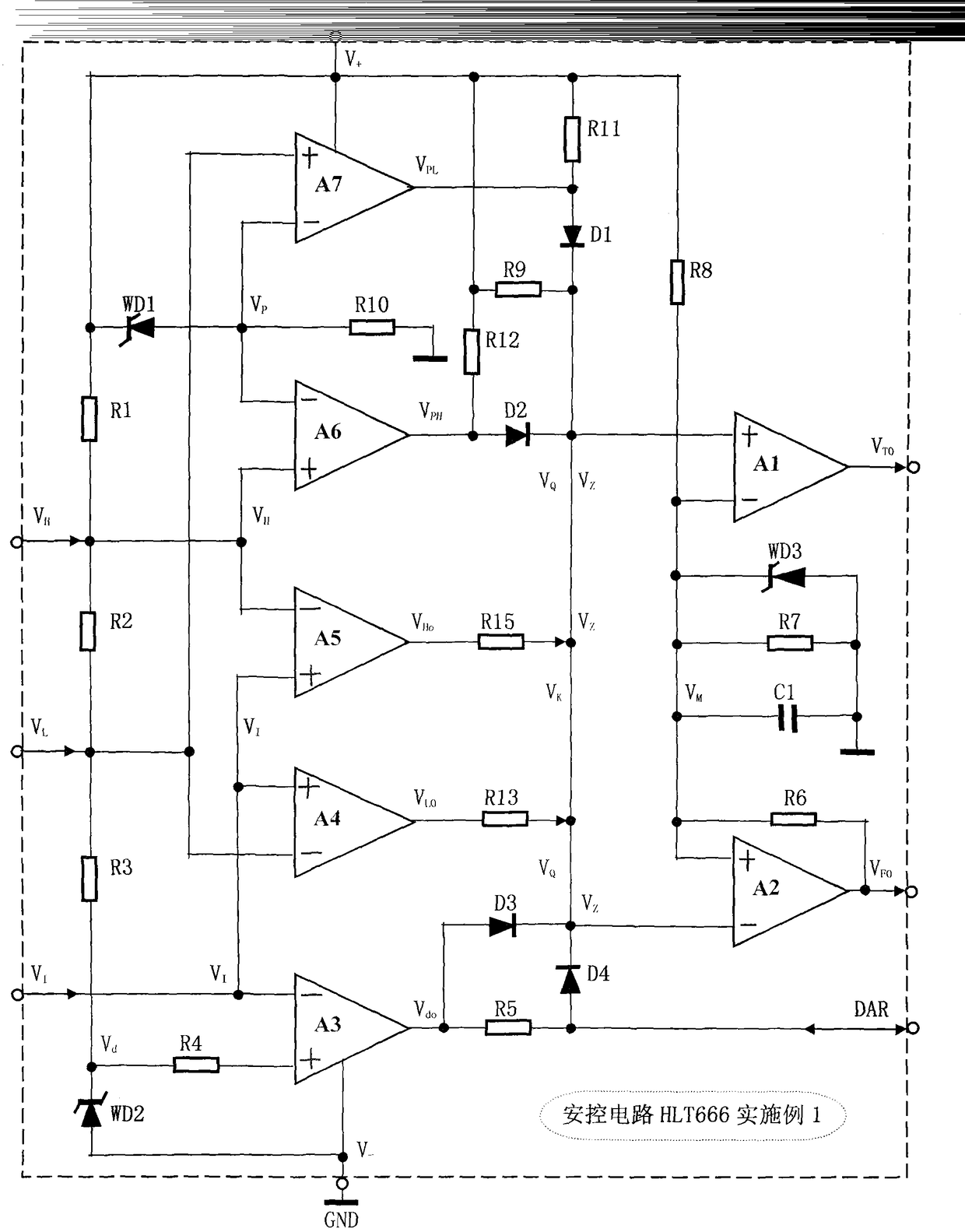

Embodiment 1

[0038] The specific circuit schematic diagram of embodiment 1, as figure 2 As shown, the over-limit conversion step difference touch circuit (1) includes operational amplifiers A4, A5, voltage dividing and limiting resistors R1, R2, R3 and conversion step difference resistors R9, R13, R15, and the capping protection circuit ( 2) include operational amplifiers A6, A7, Zener diodes WD1 and resistors R10, R11, R12, and the safety control or amplifier circuit (3) includes operational amplifiers A3 and resistors R4, R5, and the bottom circuit ( 4) comprise Zener diode WD2, described OR gate circuit (5) comprises diode D1, D2, D3, D4, described complementary bistable state or Schmitt trigger circuit (6) comprises operational amplifier A1, A2 and Zener diode WD3, resistors R6, R7, R8 and anti-interference capacitor C1; the resistor R2 is connected in series between resistors R1 and R3, the other end of resistor R3 is connected to the negative pole of Zener diode WD2, and the positiv...

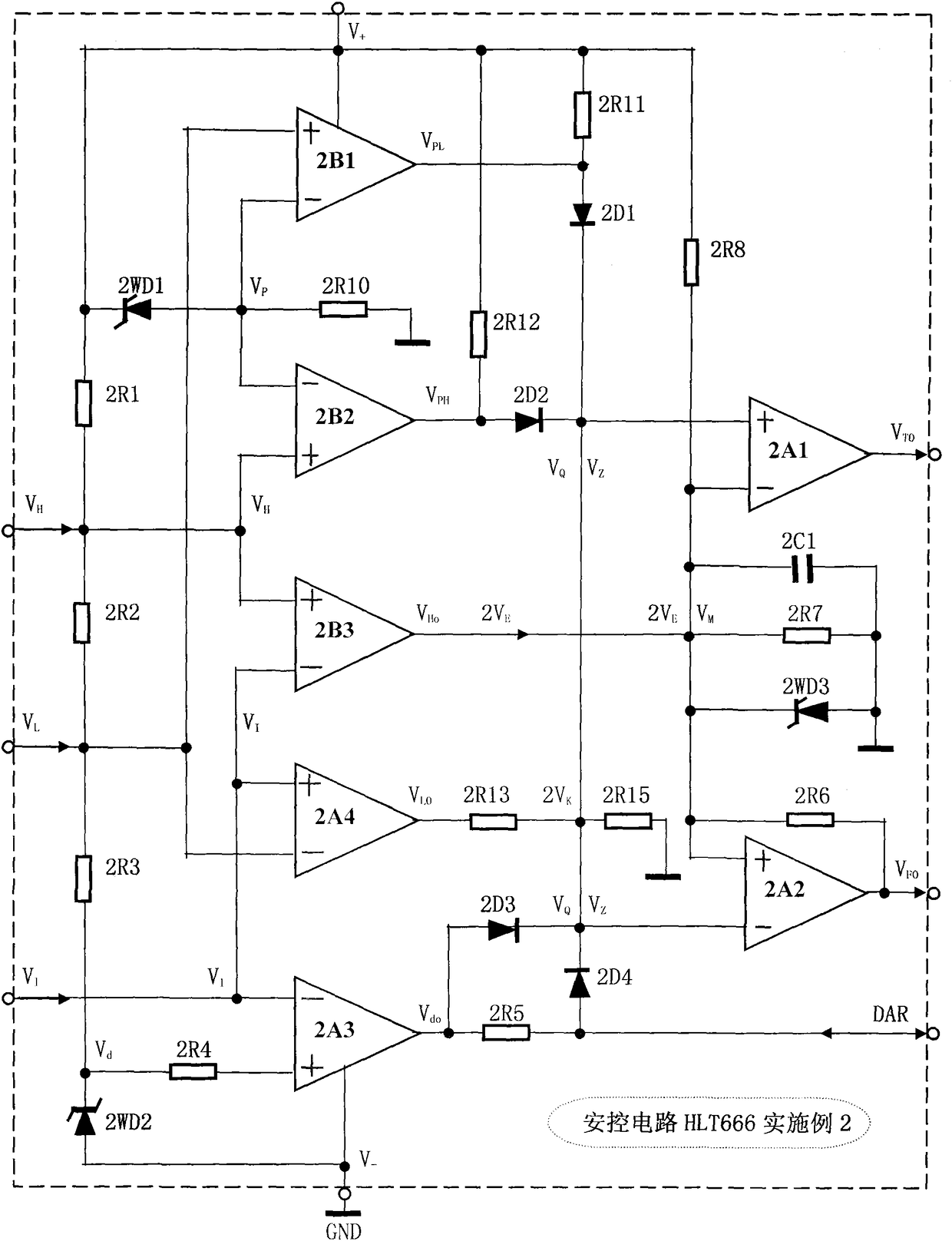

Embodiment 2

[0050] The specific circuit schematic diagram of embodiment 2, as image 3 As shown, the off-limit conversion step difference touch circuit (1) includes an operational amplifier 2A4, a voltage comparator 2B3, voltage dividing and limiting resistors 2R1, 2R2, 2R3 and conversion step difference resistors 2R13, 2R15, and the capping protection circuit (2) comprise voltage comparator 2B1, 2B2 and Zener diode 2WD1 and resistance 2R10, 2R11, 2R12, described safety control or amplifier circuit (3) comprise operational amplifier 2A3 and resistance 2R4, 2R5, described bottom Circuit (4) comprises Zener diode 2WD2, and described OR gate circuit (5) comprises diode 2D1, 2D2, 2D3, 2D4, and described complementary bistable state or Schmitt trigger circuit (6) comprises operational amplifier 2A1 , 2A2, Zener diode 2WD3, resistors 2R6, 2R7, 2R8 and anti-interference capacitor 2C1; the resistor 2R2 is connected in series between resistors 2R1 and 2R3, and the other end of resistor 2R3 is conn...

Embodiment 3

[0062] The specific circuit schematic diagram of embodiment 3, as Figure 4 As shown, the trans-limit conversion step difference touch circuit (1) includes voltage comparators 3B3, 3B4, voltage dividing and limiting resistors 3R1, 3R2, 3R3, conversion step difference resistors 3R9, 3R13, 3R15 and diode 3D5. The capping protection circuit (2) includes voltage comparators 3B1, 3B2, Zener diodes 3WD1 and resistors 3R10, 3R11, 3R12, and the bottom-out safety control or amplifier circuit (3) includes operational amplifiers 3A3 and resistors 3R4, 3R5. The bottom circuit (4) described above includes a Zener diode 3WD2, the OR circuit (5) includes diodes 3D1, 3D2, 3D3, 3D4, and the complementary bistable or Schmitt trigger circuit (6) includes Operational amplifiers 3A1, 3A2, Zener diode 3WD3, resistors 3R6, 3R7, 3R8 and anti-interference capacitor 3C1; the resistor 3R2 is connected in series between resistors 3R1 and 3R3, and the other end of resistor 3R3 is connected to the negative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com