Method for characterizing nano-porous material

A nanoporous, characterization technology, used in image data processing, instrumentation, computing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

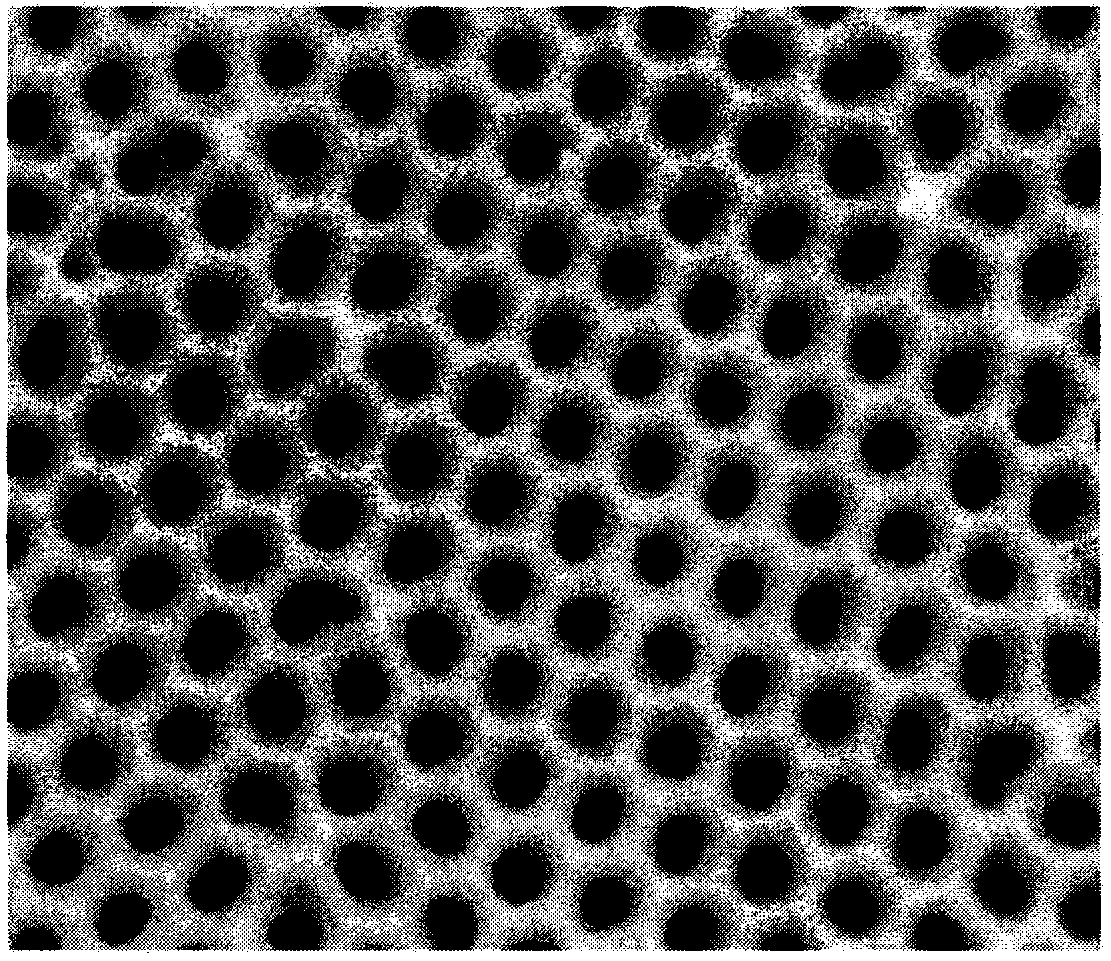

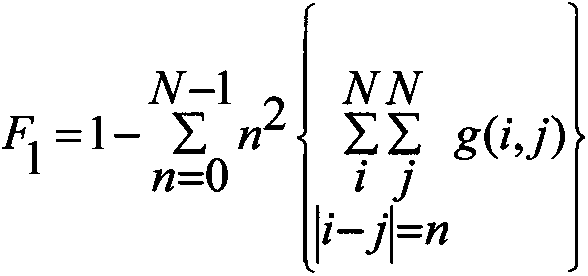

[0032] The following is an example of measuring an alumina nanoporous film sample using a FEI Quanta FEG 450 scanning electron microscope. The film structure has non-connected pores between 20 and 100 nanometers, and its microstructure is as figure 1 shown. It should be noted that although the above-mentioned scanning electron microscope is used in this embodiment, this method can also be implemented by scanning tunneling microscope (STM), atomic force microscope (AFM) or other devices that can realize microscopic scanning imaging and form moiré. accomplish.

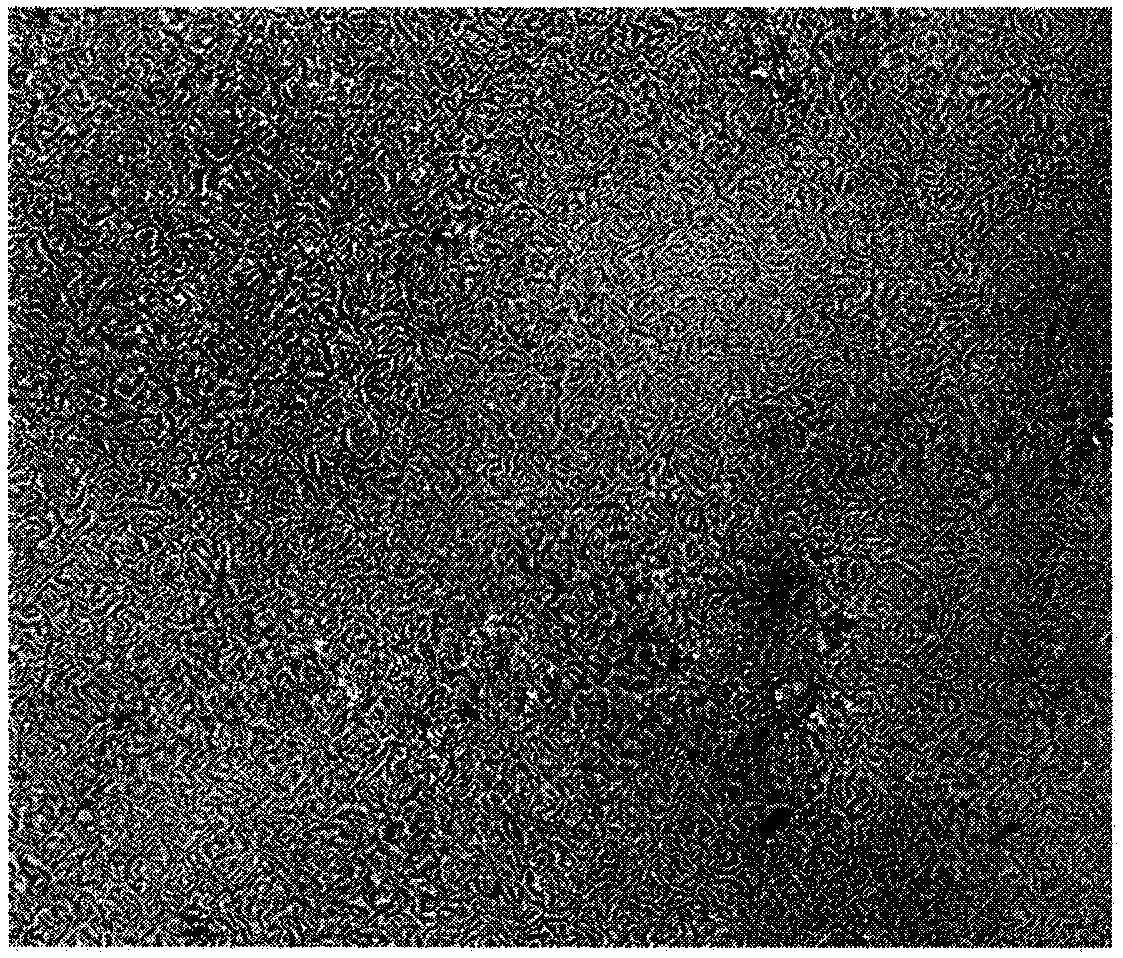

[0033] First, the nanoporous material to be tested is processed into a rectangular film sample with a thickness of 0.2 mm and placed on the sample stage of the scanning electron microscope, and the magnification and working distance are adjusted. When the magnification is 1800 times and the working distance is At 11.6mm, moiré fringe images will be generated in the scanning electron microscope display, and the moiré fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com