Solar Module Static Pressure Testing Machine

A solar module, static pressure testing technology, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor devices, etc., to achieve the effect of efficient and simple structure and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

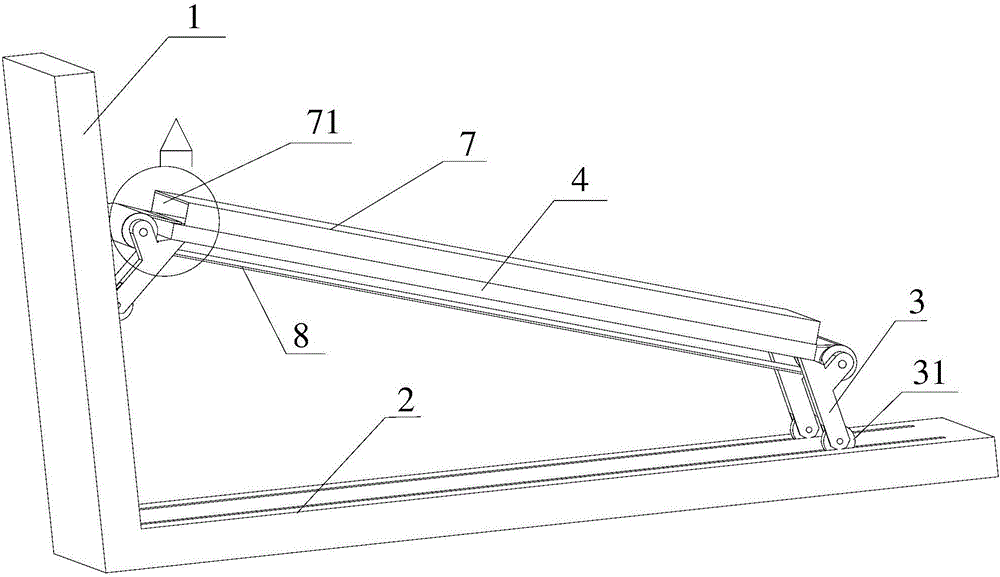

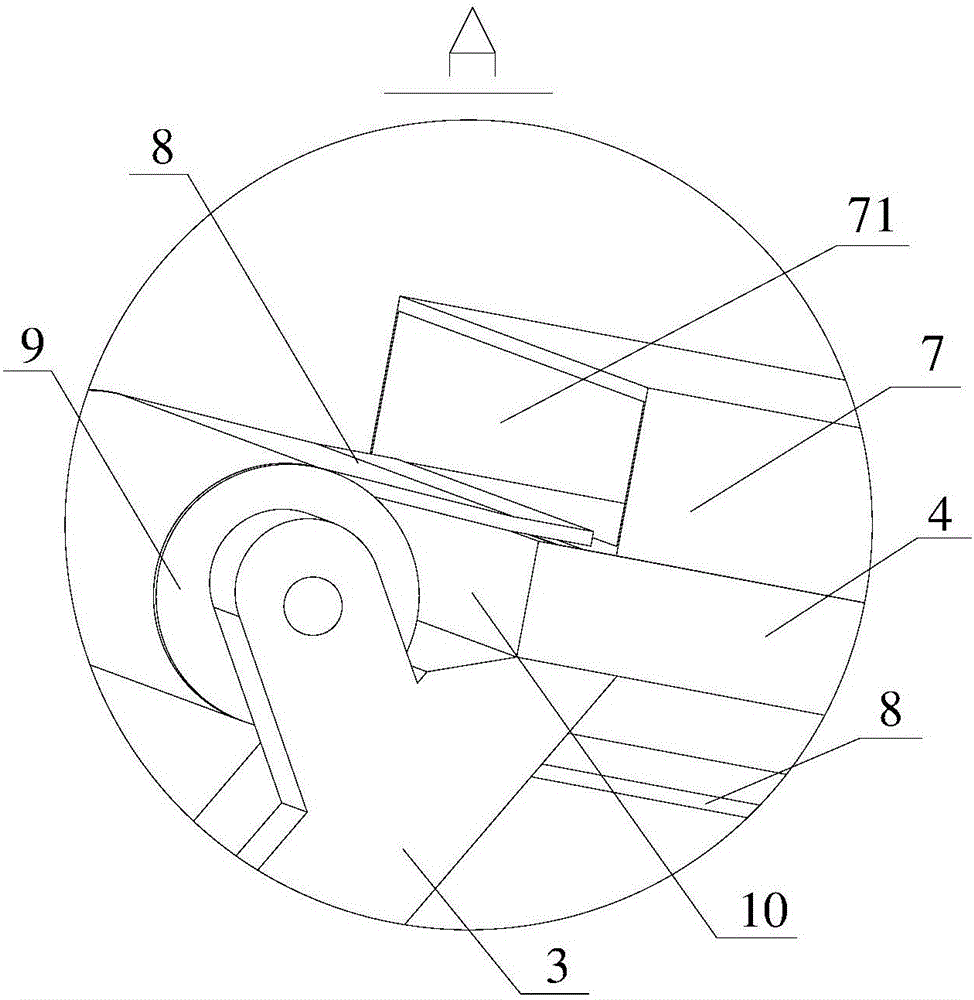

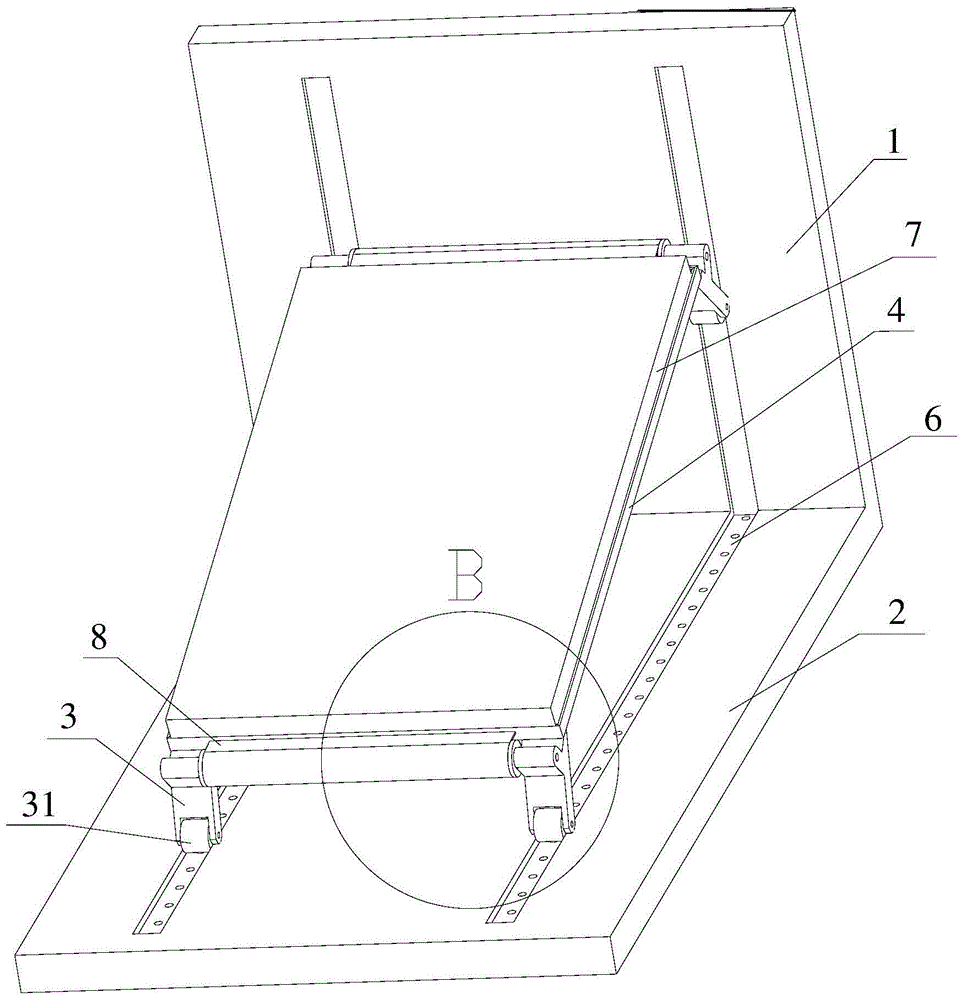

[0022] Such as figure 1 and 3 As shown, a solar module static pressure testing machine includes an L-shaped support plate, a movable mechanism 3 slidingly connected with the support plate, a solar module fixedly installed on the movable mechanism 3, and a pressure device;

[0023] Specifically, the support plate includes L-shaped support plate one 1 and support plate two 2, and the support plate one 1 and support plate two 2 are perpendicular to each other, and the movable mechanism 3 is obliquely arranged on the support plate, so One end of the movable mechanism 3 is slidably connected to the support plate 1, and the other end is slidably connected to the support plate 2; the left and right frames 4 of the solar module are fixedly connected to the movable mechanism 3; the pressure applying device includes a flat cuboid shaped storage bag7. In this embodiment, the lower surface in contact with the solar module is a wooden box made of cloth, and the upper surface of the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com