Brush system for an electric motor

A technology of electric motors and brushes, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problem of increasing the manufacturing cost and assembly cost of the brush system, the difficulty in positioning the components of the cable-guided brush system, and the unfavorable efficiency of conductor traces And save space and other issues, to achieve the effect of optimizing electromagnetic compatibility, simplifying maintenance or repair, and low-cost protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

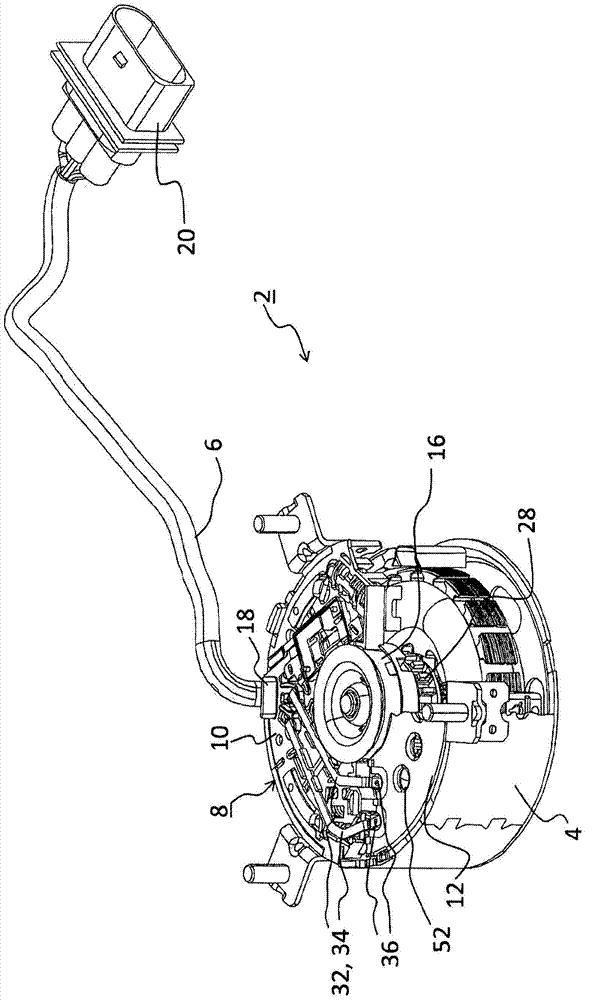

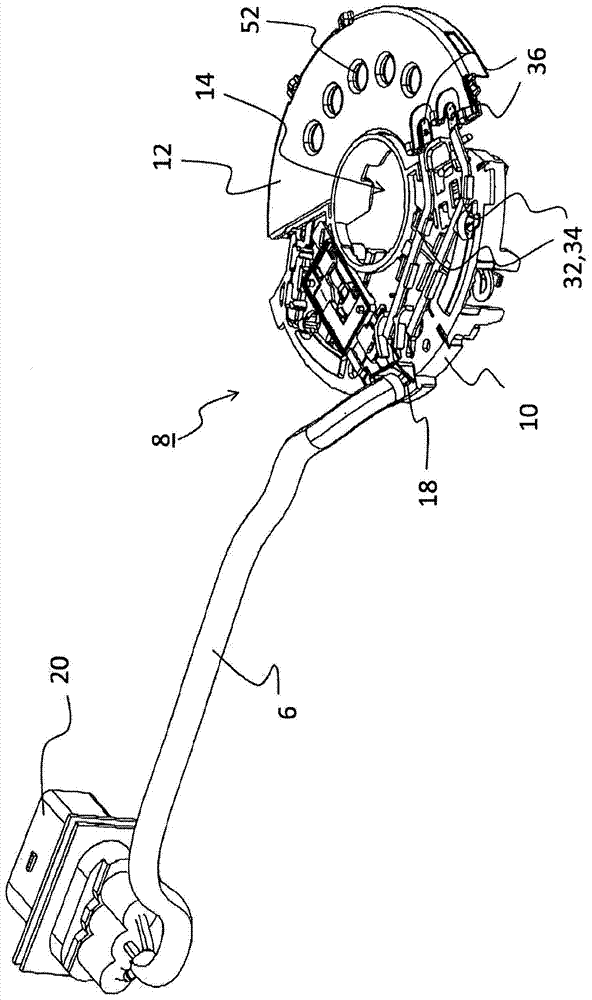

[0028] figure 1 Shown is an electric drive 2 with a motor housing 4 made of metal and with electrical cables 6 for connection to conductor lines and a brush system 8 . The brush system 8 is substantially circular and is formed on one side by a semi-circular carrier plate 10 of non-conductive material, in particular plastic, and on the other side by a likewise semi-circular metallic resistor. The device housing 12 is formed. The brush system 8 has a central recess 14 in which the electric motor 16 is arranged in the assembled state. In the assembled state, the brush system 8 is coupled to the motor housing 4 . The cable 6 has a plug connection 18 to the drive 2 on the motor side and a plug connection 20 on the conductor line side.

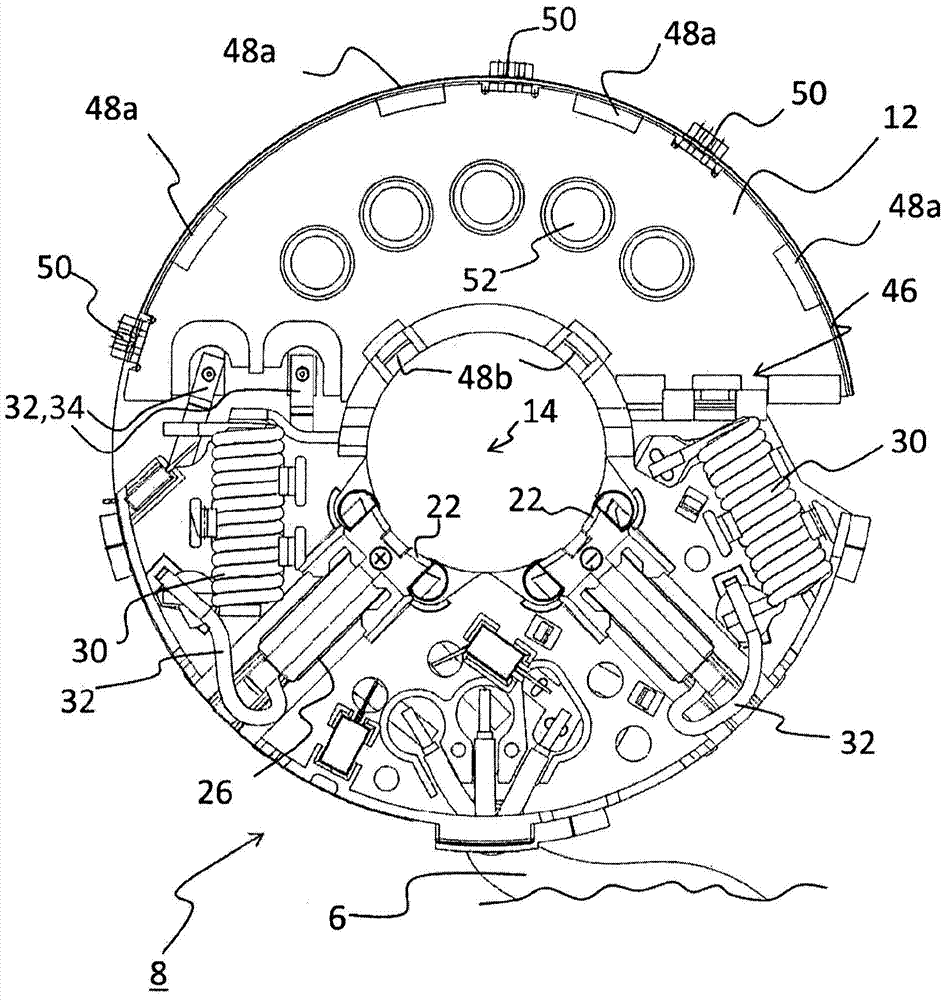

[0029] exist figure 2 and image 3 The brush system 8 is shown in more detail in . On the underside ( image 3 ), two carbon brushes 22 are arranged as sliding contacts on the periphery of the not-shown rotor of the electric motor 16 . As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com