An automatic filling production system

An automatic filling and production system technology, applied in packaging, bottling machines, bottle filling, etc., can solve the problems of loose capping, huge human resource consumption, high production cost, etc., achieve accurate filling speed and save manpower Resources, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

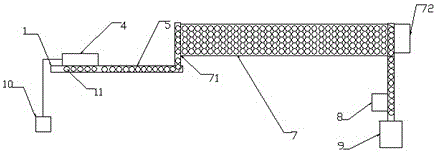

[0036] like Figure 1-7 As shown, an automatic filling production system is used for filling and packaging liquid wax products, including an assembly line 1, a multi-head automatic filling device 4, a multi-stage cooling device and an automatic capping mechanism 8.

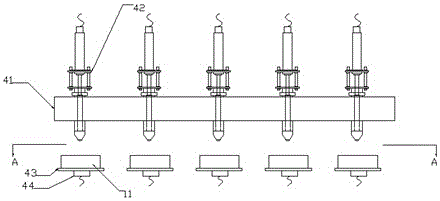

[0037] The multi-head automatic filling device 4 is located on the assembly line 1 and includes a conveyor chain 47, a wax tube 41 and five filling mechanisms arranged on the wax tube 41 in sequence.

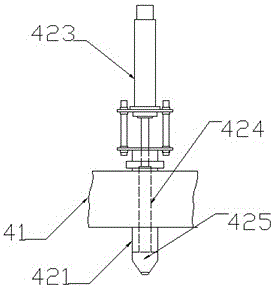

[0038] like Figure 1-2As shown, the wax tube 41 communicates with the wax pool 10, and the filling mechanism includes a filling mechanism 72 and a weighing mechanism. The filling mechanism 42 is vertically installed in the wax tube 41, and the filling mechanism 42 includes a filling head, a filling cylinder 423 and a filling mechanism 423. Nozzle 421, filling nozzle 421 is located at the bottom of wax tube 41 and is detachably connected with wax tube 41; The shape of the piston 424 is matched; the piston rod 425 ...

Embodiment 2

[0050] All the other are identical with embodiment 1, and difference is, as Figure 8 As shown, there is also a skinning zone 6 for skinning the wax liquid between the solidification zone 7 and the volatilization zone 5, and the number of parallel wax tanks conveyed by the volatilization zone 5, the skinning zone 6 and the solidification zone 7 increases successively.

[0051] Crust zone 6 includes a crust zone conveyor belt and crust cooling equipment, the crust zone conveyor belt is a double-row wax tank conveyor belt, and the crust cooling equipment includes a crust refrigerator, a crust zone fan and a cover located in the crust zone The crust cooling cover above the conveyor belt, the crust cooler and the fan in the crust area are all arranged in the crust cooling cover.

[0052] The crust cooler is communicated with the central controller. When the temperature sensor senses that the temperature of the bottom of the tank at the outlet of the solidification zone is higher t...

Embodiment 3

[0055] All the other are identical with embodiment 2, and difference is, as Figure 9-10 As shown, the automatic filling production system also includes a coding can turning mechanism, which is located at the upstream end of the multi-head automatic filling device, including a conveyor belt 31, a coding gun 3 and a can turning mechanism 2, and the coding gun 3 and the can turning mechanism 2 are sequentially arranged on the conveyor belt 31, and the coding gun 3 and the can turning mechanism 2 are respectively connected to the central controller through communication. The can-spraying can turning mechanism also includes an electronic sensor 32 for sensing that the wax can is in place. The electronic sensor 32 is arranged on the assembly line and corresponds to the position of the coding gun 3 and the can-turning mechanism 2 respectively. The electronic sensor 32 communicates with the central The controller, when the electronic sensor 32 senses the wax can, sends the wax can in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com