Concrete pavement brick with water permeability and preparation method thereof

A technology of concrete pavement and water permeability, applied in the municipal field, can solve the problems of easy fading, low strength, impermeability, etc., and achieve the effect of good bending resistance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

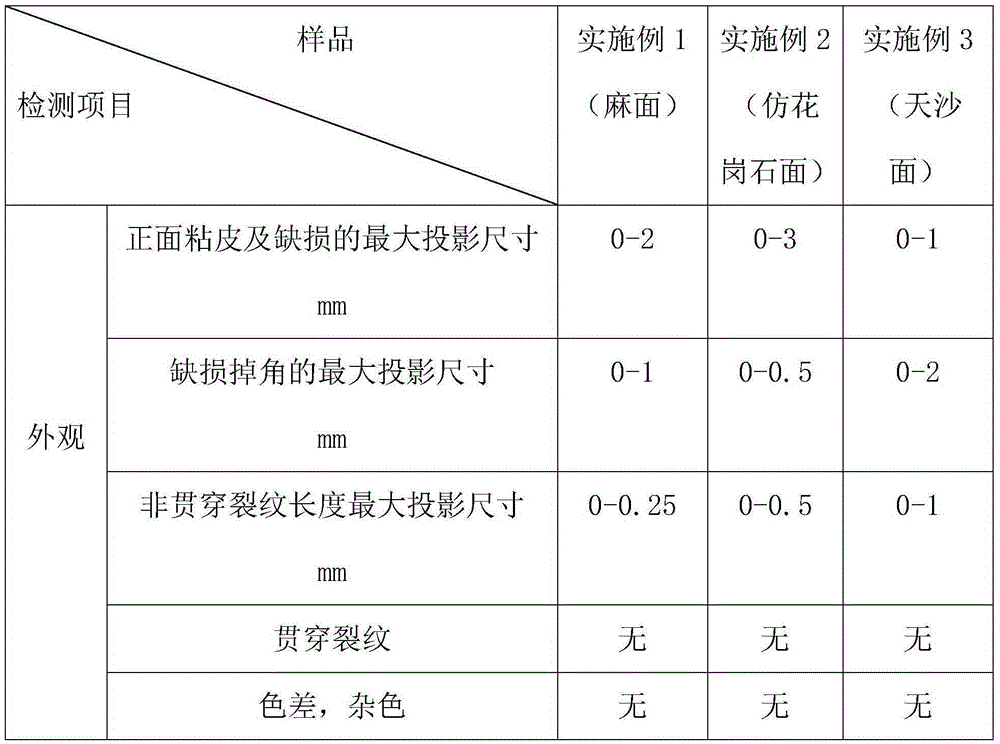

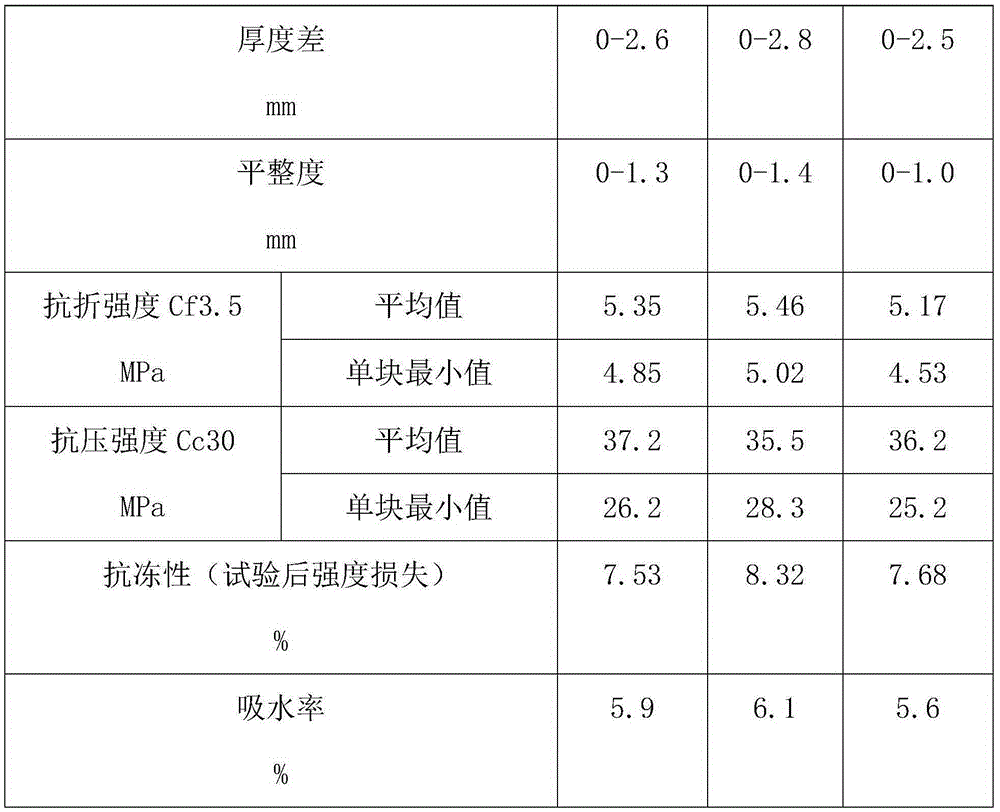

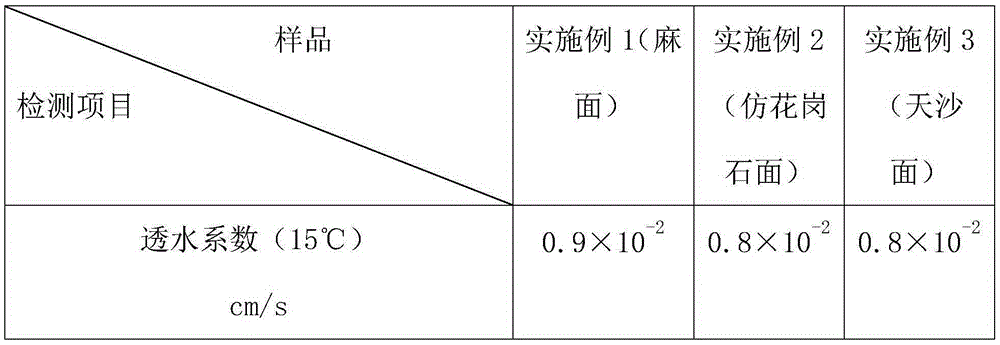

Examples

Embodiment 1

[0026] The preparation of embodiment 1 pitted concrete pavement brick

[0027] ①Weigh the fabric and bottom material.

[0028] Said that 100 parts by weight of No. 42.5 cement, 300 parts by weight of quartz sand, 4 parts by weight of pigment and 25 parts by weight of water were mixed together as the fabric.

[0029] Said 200 parts by weight of No. 42.5 cement, 100 parts by weight of 0.5cm pebble or ore, 850 parts by weight of 200 mesh pebble crushed powder, 850 parts by weight of 200 mesh ore crushed powder and 110 parts by weight of water are mixed together as base material.

[0030] ② Stir the fabric and bottom material separately.

[0031] ③Product molding and demoulding. Product forming and demoulding are carried out in U18-15 pallet-free brick machine.

[0032] Product forming: lower the mold frame, raise the pressure head, then open the bottom material door, the bottom material truck feeds the bottom material for cloth, shake the mold frame to make the bottom material...

Embodiment 2

[0036] Embodiment 2 Preparation of imitation granite face concrete pavement brick

[0037] ①Weigh the fabric and bottom material.

[0038] Said that 100 parts by weight of No. 42.5 cement, 210 parts by weight of quartz sand, 90 parts by weight of granite, parts by weight of pigment, and 25 parts by weight of water were mixed together as the fabric.

[0039] Said 200 parts by weight of No. 42.5 cement, 100 parts by weight of 0.5cm pebble or ore, 850 parts by weight of 200 mesh pebble crushed powder, 850 parts by weight of 200 mesh ore crushed powder and 110 parts by weight of water are mixed together as base material.

[0040] ② Stir the fabric and bottom material separately.

[0041] ③Product molding and demoulding. Product forming and demoulding are carried out in U18-15 pallet-free brick machine.

[0042] Product forming: lower the mold frame, raise the pressure head, then open the bottom material door, the bottom material truck feeds the bottom material for cloth, shake ...

Embodiment 3

[0046] The preparation of embodiment 3 day sand surface concrete pavement brick

[0047] ①Weigh the fabric and bottom material.

[0048] Say 100 weight parts of No. 42.5 cements, 300 weight parts of river sands, 4 weight parts of pigments, 25 weight parts of water mix together, as lining.

[0049] Said 200 parts by weight of No. 42.5 cement, 100 parts by weight of 0.5cm pebble or ore, 850 parts by weight of 200 mesh pebble crushed powder, 850 parts by weight of 200 mesh ore crushed powder and 110 parts by weight of water are mixed together as base material.

[0050] ② Stir the fabric and bottom material separately.

[0051] ③Product molding and demoulding. Product forming and demoulding are carried out in U18-15 pallet-free brick machine.

[0052] Product forming: lower the mold frame, raise the pressure head, then open the bottom material door, the bottom material truck feeds the bottom material for cloth, shake the mold frame to make the bottom material flat, then return ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com