Preparation method and system of lanthanum acetate

A preparation system and technology of lanthanum acetate, applied in the field of preparation of lanthanum acetate, can solve the problems of not being able to consult patent documents, difficult to achieve, etc., and achieve the effects of easy filtration and drying, short reaction time and high total amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

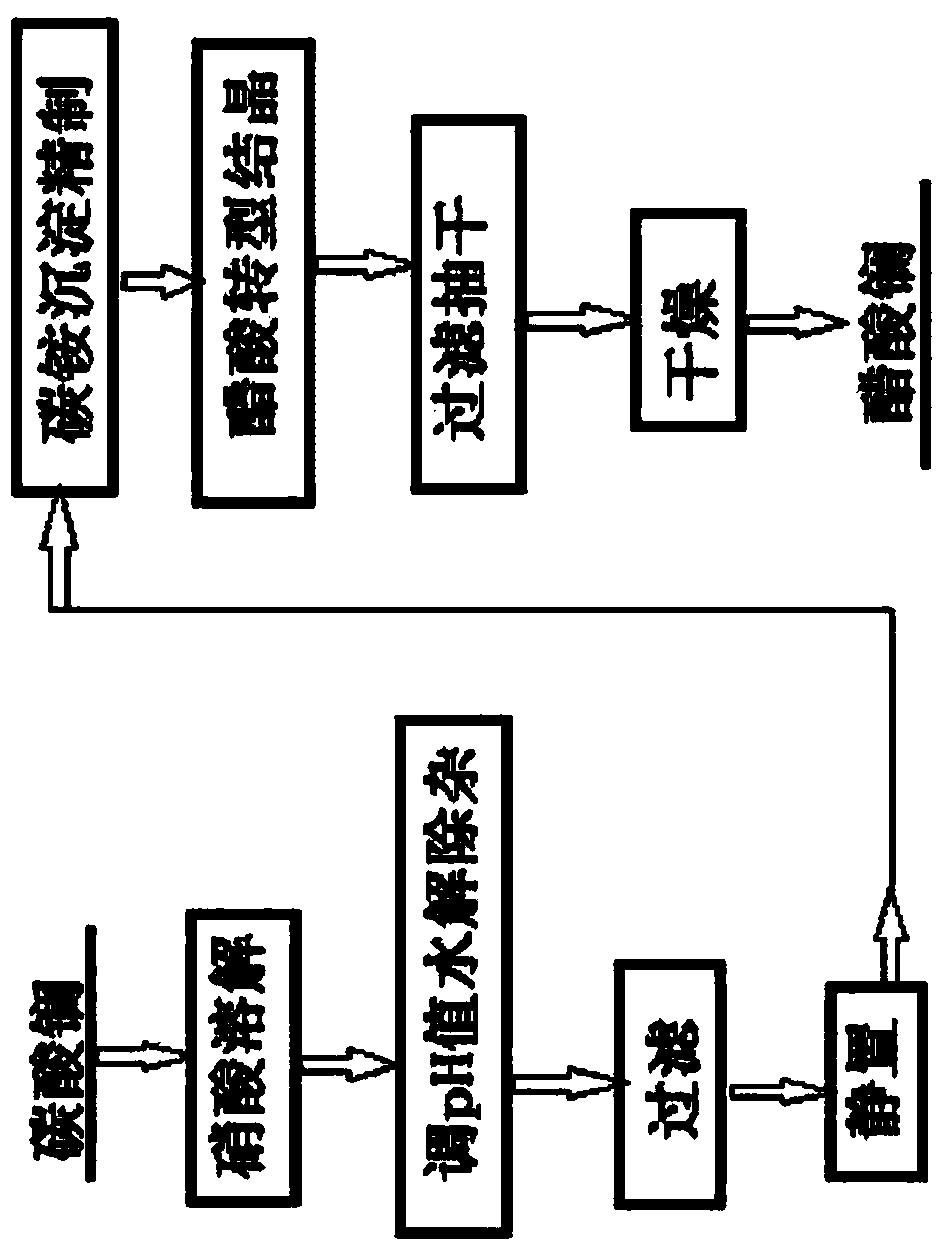

Method used

Image

Examples

Embodiment Construction

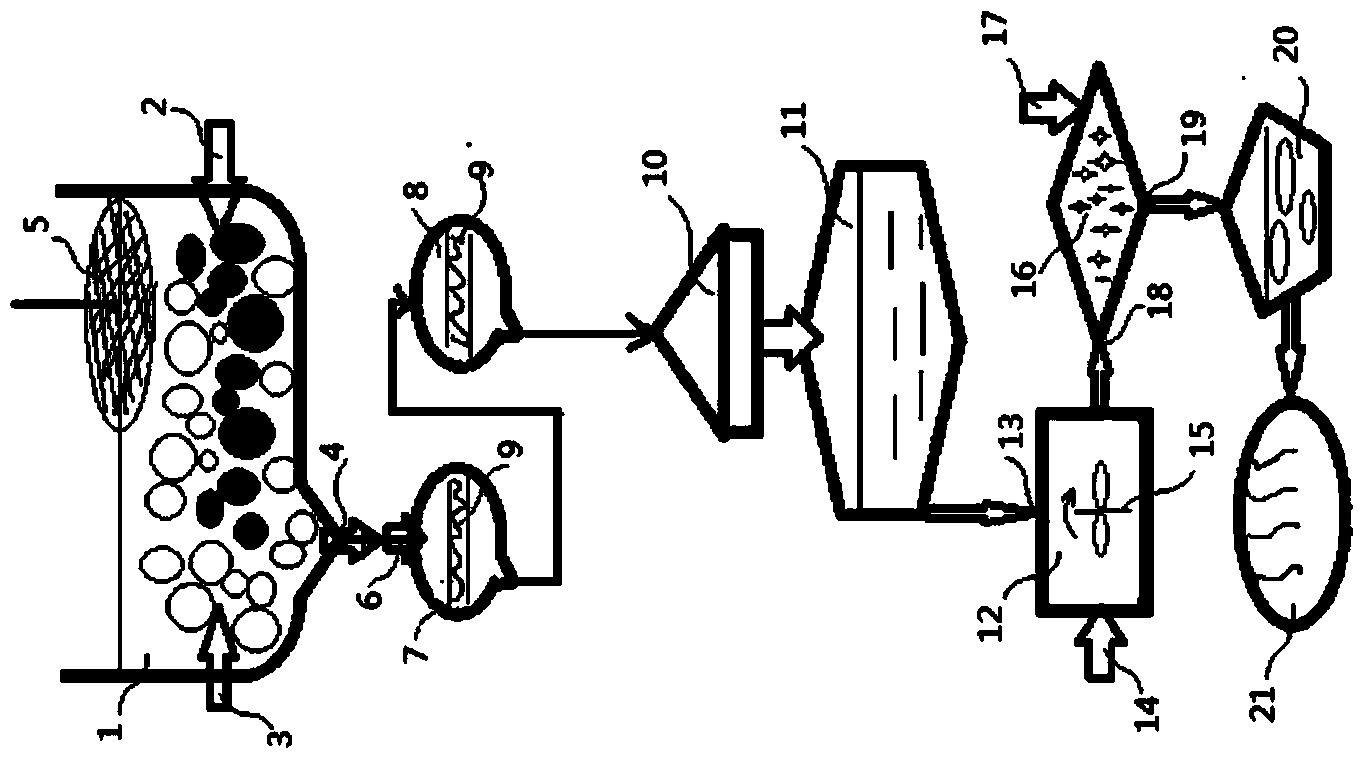

[0034] Such as figure 2 As shown, the system for preparing high-purity and high-volume lanthanum acetate according to the present invention comprises: dissolution reactor 1, lanthanum carbonate inlet 2, nitric acid inlet 3, lanthanum nitrate feed liquid output 4, oil removal device 5, lanthanum nitrate Feed liquid inlet 6, primary airtight filter tank 7, secondary airtight filter tank 8, double-layer filter cloth with filter paper in the middle 9, precision filter pump 10, storage tank 11, precipitation reaction kettle 12, lanthanum nitrate feed liquid Entry port 13, ammonium bicarbonate solution entry port 14, stirring device 15, crystallization reactor 16, acetic acid entry port 17, refined lanthanum carbonate feed liquid entry port 18, lanthanum acetate feed liquid output port 19, filtration and drying device 20, drying device 21.

[0035] The technological scheme is as follows:

[0036] Put high-purity lanthanum carbonate (>99.99%) quantitatively into reactor 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com