An extraction column chromatography for separating la, ce, pr, nd mixed rare earth ions

A mixed rare earth and extraction column technology, which is applied in the extraction column chromatography for separating La, Pr, Nd mixed rare earth ions, in the field of Ce, can solve the problems of large amount of acid and alkali, complicated separation process, low separation efficiency, etc. High purity, high separation efficiency, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1): Preparation of chromatographic column packing:

[0024] Weigh 80g of diatomite with a particle size of 100 mesh and place it in a 500mL beaker, add about 200mL of deionized water, stir for 30 minutes, then filter with suction, discard the filtrate; add about 200mL of absolute ethanol, stir for 30 minutes, then filter with suction, discard Remove the filtrate; add about 200mL deionized water, stir for 30 minutes and then suction filter, discard the filtrate; soak the diatomite after washing with 200mL 10% hydrochloric acid solution for 24 hours; wash the diatomite after acid leaching with deionized water until After neutralization, dry it for later use.

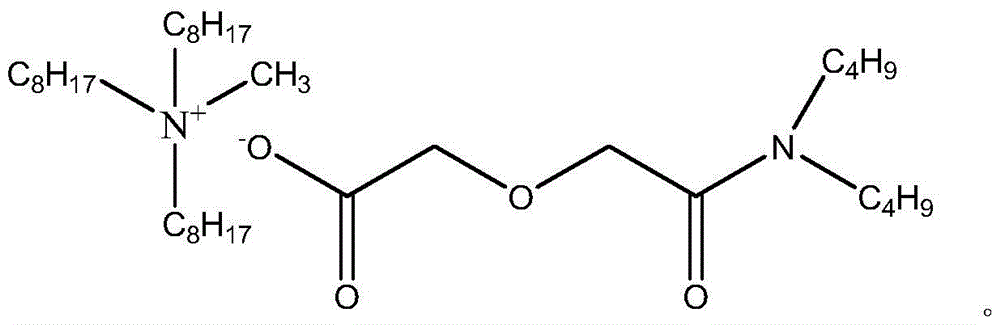

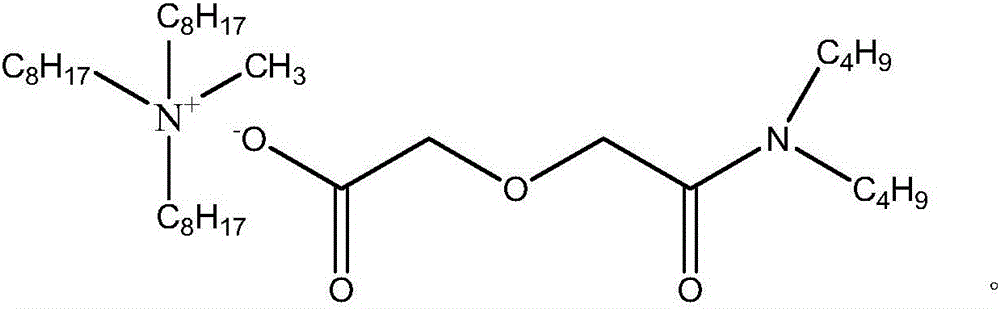

[0025] Weigh 20g of [A336][BDGA] ionic liquid, dilute with 60g petroleum ether / acetone (V / V=8 / 2) diluent, mix with 60g of activated diatomaceous earth, stir for 12 hours, then rotary evaporate Remove the thinner and dry for later use.

[0026] (2): Preparation of mixed rare earth samples:

[0027] Preparation co...

Embodiment 2

[0033] (1): Preparation of chromatographic column packing:

[0034] Weigh 40g of diatomite with a particle size of 300 mesh and place it in a 500mL beaker, add about 200mL of deionized water, stir for 30 minutes, then filter with suction, discard the filtrate; add about 200mL of absolute ethanol, stir for 30 minutes, then filter with suction, discard Remove the filtrate; add about 200mL deionized water, stir for 30 minutes and then suction filter, discard the filtrate; soak the diatomite after washing with 200mL 10% hydrochloric acid solution for 24 hours; wash the diatomite after acid leaching with deionized water until After neutralization, dry it for later use.

[0035] Weigh 15g of [A336][BDGA] ionic liquid, dilute with 30g of kerosene / ethanol (V / V=8 / 2) diluent, mix evenly with 30g of activated diatomaceous earth, stir for 12 hours, and remove by rotary evaporation Thinner, dried for later use.

[0036] (2): Preparation of mixed rare earth samples:

[0037] Prepare the ...

Embodiment 3

[0043] (1): Preparation of chromatographic column packing:

[0044]Weigh 50g of diatomite with a particle size of 200 mesh and place it in a 500mL beaker, add about 200mL of deionized water, stir for 30 minutes, then filter with suction, discard the filtrate; add about 200mL of absolute ethanol, stir for 30 minutes, then filter with suction, discard Remove the filtrate; add about 200mL deionized water, stir for 30 minutes and then suction filter, discard the filtrate; soak the diatomite after washing with 200mL 10% hydrochloric acid solution for 24 hours; wash the diatomite after acid leaching with deionized water until After neutralization, dry it for later use.

[0045] Weigh 15g [A336][BDGA] ionic liquid, dilute with 60g petroleum ether / ethanol (V / V=8 / 2) diluent, mix with 60g activated diatomaceous earth, stir for 12 hours, then rotary evaporate Remove ethanol and dry for later use.

[0046] (2): Preparation of mixed rare earth samples:

[0047] Preparation concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com