Device and method for integrating well dredging and well flushing, and well logging of cement bond well cementing quality

A technology of cement bonding and quality, which is applied in the directions of flushing wellbore, wellbore/well components, earth-moving drilling, etc. It can solve the problems of high logging cost, complicated equipment and long time consumption of single well, and achieve good market application prospects. The effect of saving logging time and reducing the number of times equipment goes down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

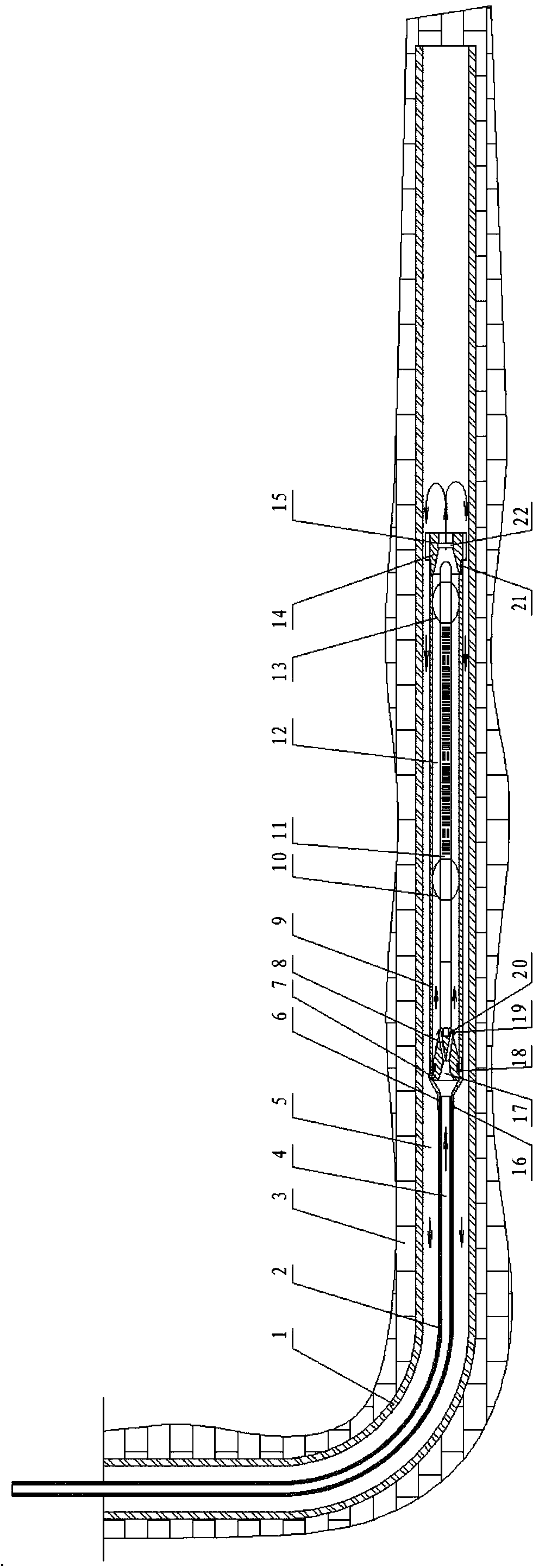

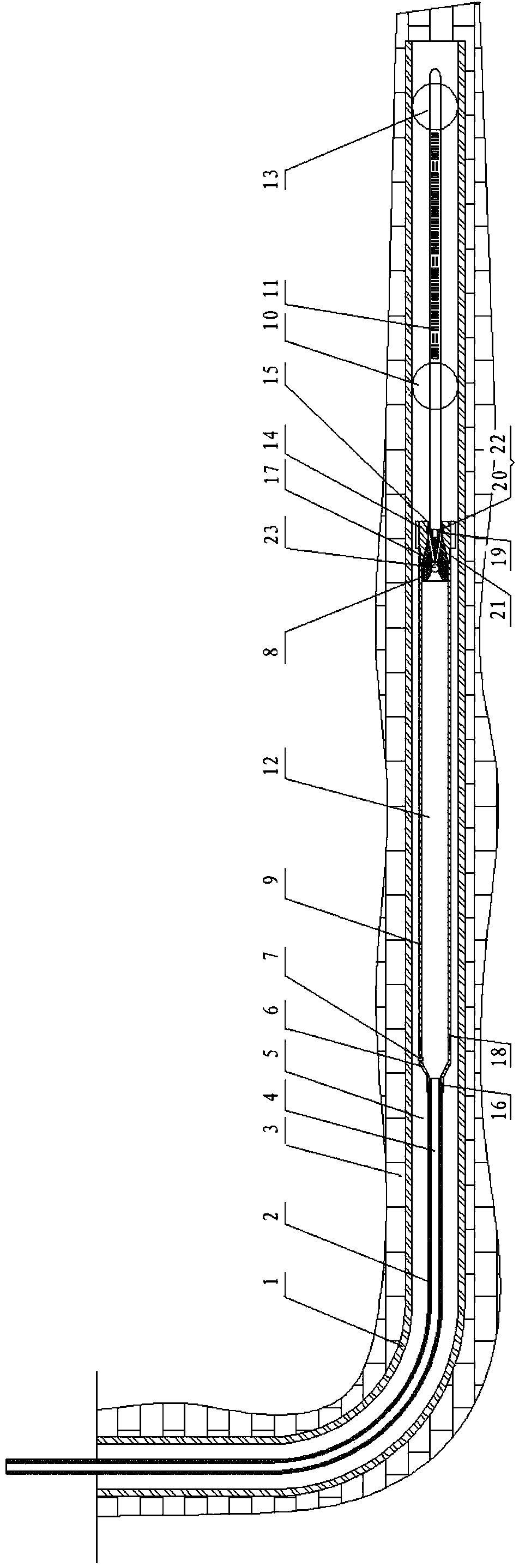

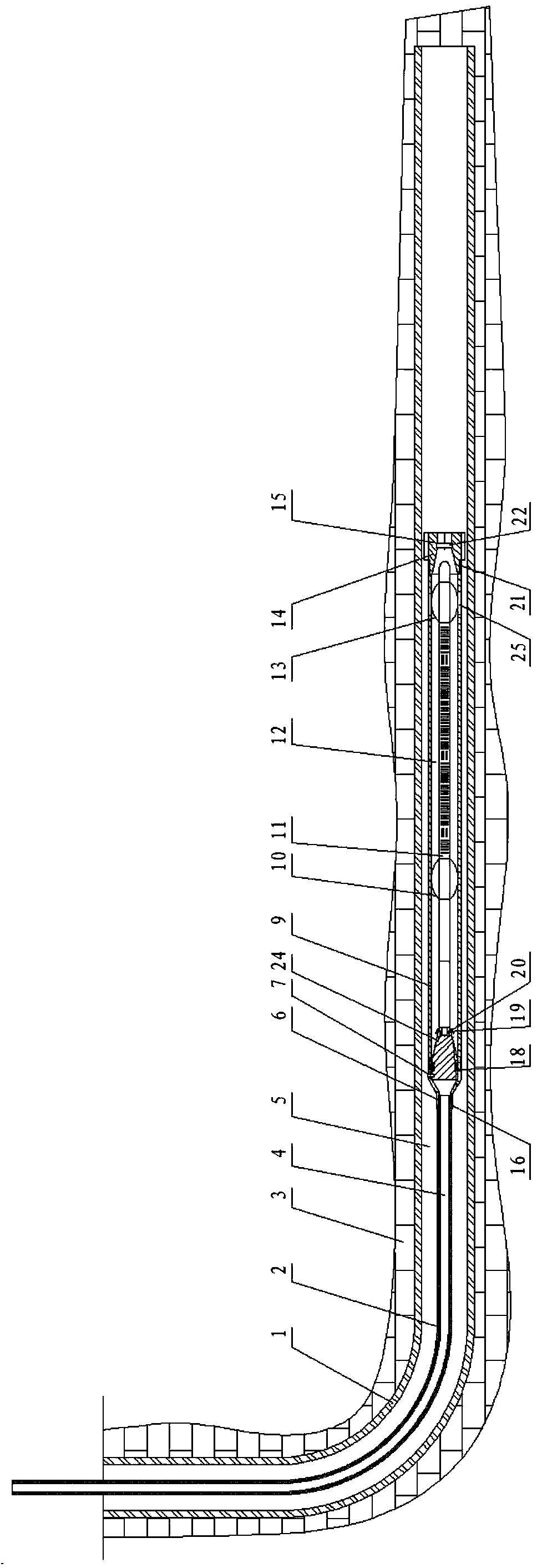

[0045] refer to figure 1 and figure 2 As shown, the first embodiment of the present invention is an integrated process technology for drilling, flushing, cementing, cementing, and cementing of horizontal wells, and its construction equipment includes coiled tubing, ordinary tubing or drill pipe connected from top to bottom. 2. Adapter 6, protection tube 9, piston I 8, instrument string 11, well gauge 14 and ball 23 thrown in during work.

[0046] refer to figure 1 As shown, the horizontal well drilling, well cleaning, cement bonding and cementing quality logging integrated device includes coiled tubing, common tubing or drill pipe 2 extending into the oil well and connected from top to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com