A reduction shaft transmission device

A transmission device and reduction shaft technology, applied in the field of transmission shafts, can solve the problems of affecting the life of needle roller bearings, unreliable positioning, easy movement of the inner ring, etc., achieve simplified structure and assembly process, simple structure, improved reliability and The effect of running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

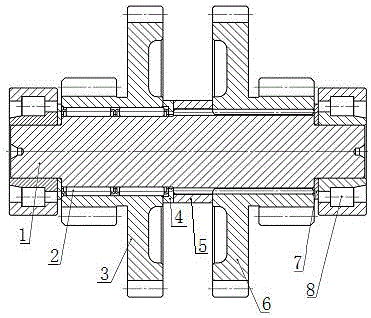

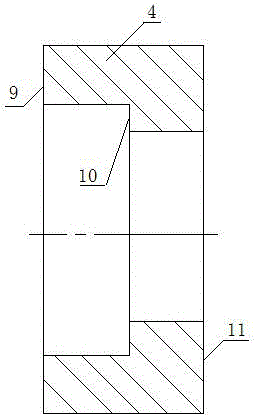

[0012] The reduction shaft transmission device of the present invention includes a transmission shaft 1 , a needle bearing 2 , a left gear 3 , a right gear 6 , and a cylindrical roller bearing 8 . A needle roller bearing spacer 4 and a drive shaft middle spacer 5 are arranged between the left gear 3 and the right gear 6 to axially locate the left gear 3 . The needle roller bearing spacer 4 is a cylindrical inner stepped spacer composed of the first end face 9, the second end face 10 and the third end face 11. The first end face 9, the second end face 10 and the third end face 11 are respectively connected with the left gear 3 , The needle roller bearing 2 is in contact with the spacer sleeve 5 in the transmission shaft. A cylindrical roller bearing spacer 7 is arranged between the right gear 6 and the cylindrical roller bearing 8 to axially locate the right gear 6 .

[0013] In order to simplify the structure and assembly process of the needle roller bearing 2, the needle rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com