Efficient oil gas pre-cooler

An oil-gas precooler, high-efficiency technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of cooling or heating fluid leakage, reduce heat transfer efficiency, etc., and achieve good defrosting effect , Improve heat transfer efficiency and prolong effective working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

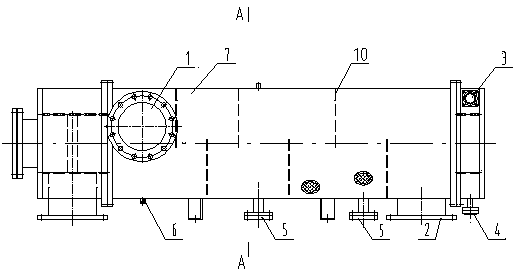

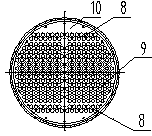

[0019] The high-efficiency oil-gas precooler shown in the accompanying drawings includes a housing 7, a condensation pipe 9, and a baffle device 10; the condensation pipe 9 is distributed in the middle of the housing 7 along the length direction of the housing 7; Inside; the shell 7 is provided with a hot oil gas inlet 1, a hot oil gas outlet 2, a refrigerant inlet 3, a refrigerant outlet 4, an oil outlet 5 and a sewage outlet 6.

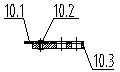

[0020] The baffle device 10 is a composite baffle, including a flexible baffle 10.1 and a rigid baffle 10.3; the flexible baffle 10.1 and the rigid baffle 10.3 are connected by copper rivets 10.2; the outer edge of the flexible baffle 10.1 is connected to the casing 7 Inner wall interference fit.

[0021] A defrosting device is provided in the casing 7, and the defrosting device includes a defrosting pipe 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com